Husking and peeling machine for acer truncatum samara and application method thereof

A peeling machine and wing fruit technology, applied in the intelligent control system, the field of Yuanbao maple wing fruit peeling and peeling machine, can solve the problems that affect the quality of processed products, the black seed coat is difficult to peel, the degree of automation is low, etc., and achieve frequent solutions. The problem of feeding and feeding quantity control, compact structure, and the effect of improving the utilization rate of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to be able to understand the technical means of the present invention more clearly, it can be implemented according to the contents of the description, and in order to make the above-mentioned and other purposes, features and advantages of the present invention more obvious and understandable, the preferred embodiments are listed below, and With accompanying drawings, the detailed description is as follows.

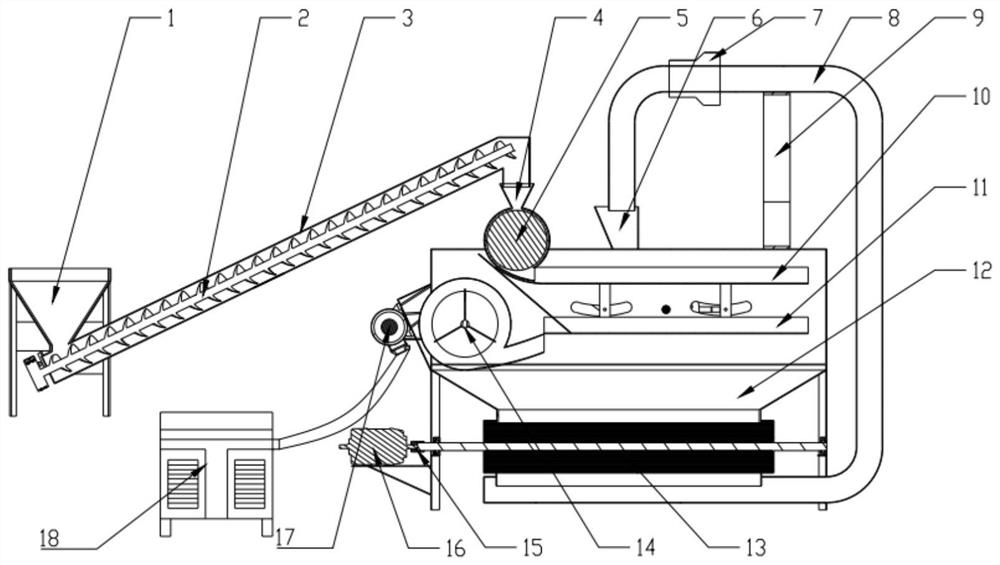

[0047] see figure 1 , the eucommia grain peeling machine of the present invention includes a material system, a shelling system, a grain sorting system and an intelligent control system;

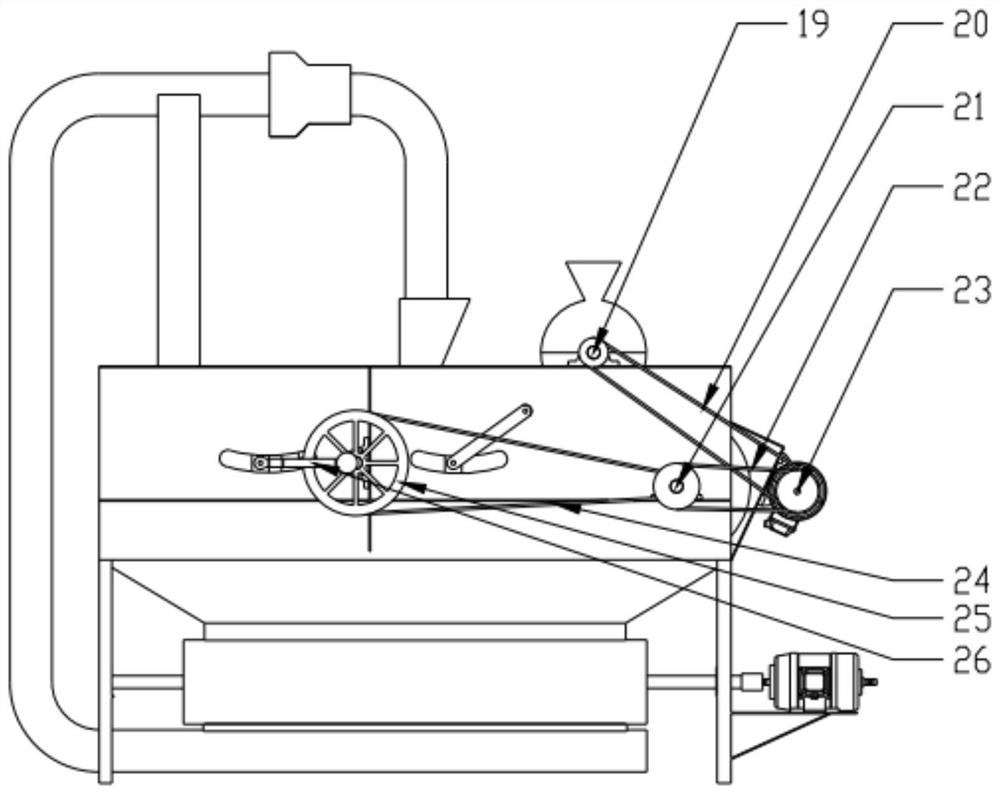

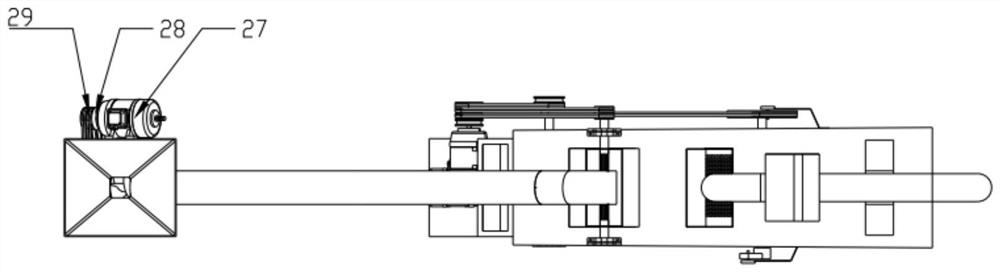

[0048] Further, see figure 1 , 2 and image 3 , the feeding system includes a trapezoidal feed bin 1, a screw shaft 2, a screw shaft tube 3, a motor three 27, a pulley four 28, a V belt four 29, and a motor three 17 passes through a V belt four 29, a pulley four 28 and the screw shaft 3 connections, the screw shaft 3 is connected to the peeling system; and the motor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com