Oil depot Internet of Things equipment state monitoring and automatic switching method

A networked equipment and automatic switching technology, applied in the direction of measuring devices, instruments, electrical components, etc., can solve the problems of oil depot safety and security hidden dangers, economics, system failure rate increase, monitoring stoppage, etc., to prevent oil-related safety incidents and reduce major accidents Risks, promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

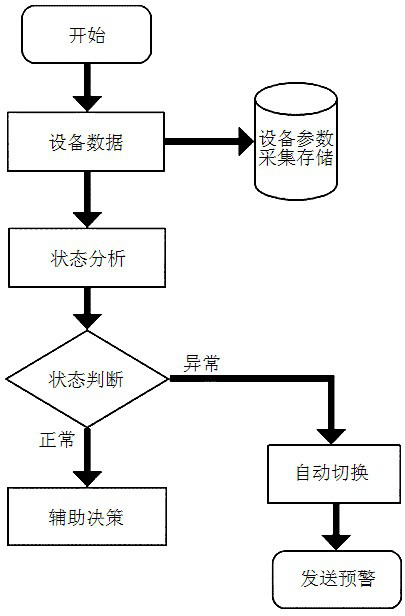

[0021] refer to figure 1 , this specific implementation mode adopts the following technical solutions: the state monitoring and automatic switching method of the oil depot Internet of Things equipment, including the equipment data module, the state analysis module, the automatic switching module, the auxiliary decision-making module, and the alarm module. Networked devices include liquid level gauges, thermometers, pressure sensors, oil and gas concentration sensors, and real-time status parameters and operating parameters of the software operating environment. The specific steps are:

[0022] (1) Liquid level gauges, thermometers, pressure sensors, and oil and gas concentration sensors of key IoT devices are installed at two points A and B of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com