Airtight packaging structure and method for microwave and millimeter wave chip with BGA interface

A hermetic packaging, millimeter wave technology, applied in electrical components, semiconductor/solid-state device parts, semiconductor devices, etc., can solve the problems of increasing link loss, difficulty in repairing, affecting product size, etc., and reducing link Loss, improve service life and reliability, convenient and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

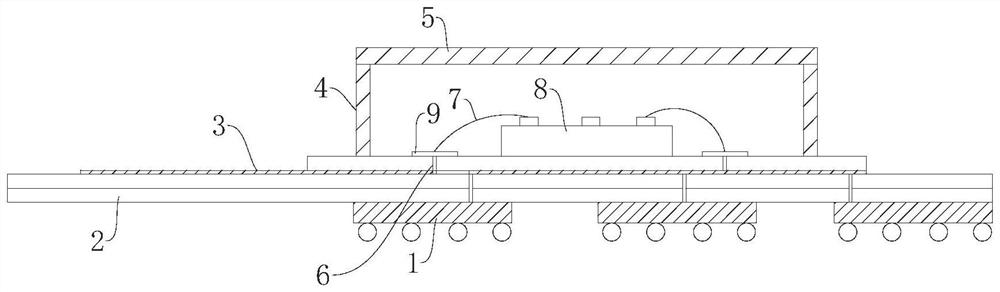

[0042] like figure 1 As shown, a microwave and millimeter wave chip hermetic packaging structure with a BGA interface includes a substrate BGA ball planting array structure 1, and an airtight substrate 2 composed of several layers of circuit substrates is arranged on the substrate BGA ball planting array structure 1. The upper surface of the airtight substrate 2 is provided with a chip assembly 8, and the substrate BGA ball planting array structure 1 passes through the airtight substrate 2 and is communicatively connected with the chip assembly 8; the airtight substrate 2 is provided with a surrounding frame 4 around the chip assembly 8. An airtight cover plate 5 is arranged on the frame 4 to form an airtight chamber for accommodating the chip assembly 8; an antenna radiator 3 is arranged on the airtight substrate 2, and a bonding end 9 is arranged on the airtight substrate 2 in the airtight chamber, The antenna radiator 3 passes through the airtight substrate 2 and is connect...

Embodiment 2

[0055] The content of the above-mentioned embodiment 1 describes a microwave and millimeter-wave chip hermetic packaging structure provided with a BGA interface. This embodiment also discloses other feasible packaging structure solutions, which are now described.

[0056] In this embodiment, the setting structure of the chip assembly 8 is optimized, as follows:

[0057] like Figure 4 As shown, the upper surface of the airtight substrate 2 is provided with a chip BGA ball planting array structure 10, and the bonding end of the chip assembly 8 is bonded and connected to the chip BGA ball planting array structure 10; the chip BGA ball planting array The structure 10 is communicatively connected with the substrate BGA ball planting array structure 1 by passing through the airtight substrate. When such a solution is adopted, the chip components are set up in reverse, and the chip BGA ball planting array structure is connected to the airtight substrate and communicates with the su...

Embodiment 3

[0062] The content of the above-mentioned embodiment 1 describes a microwave and millimeter-wave chip hermetic packaging structure provided with a BGA interface. This embodiment also discloses other feasible packaging structure solutions, which are now described.

[0063] This embodiment optimizes and improves the settings of the chip components, specifically:

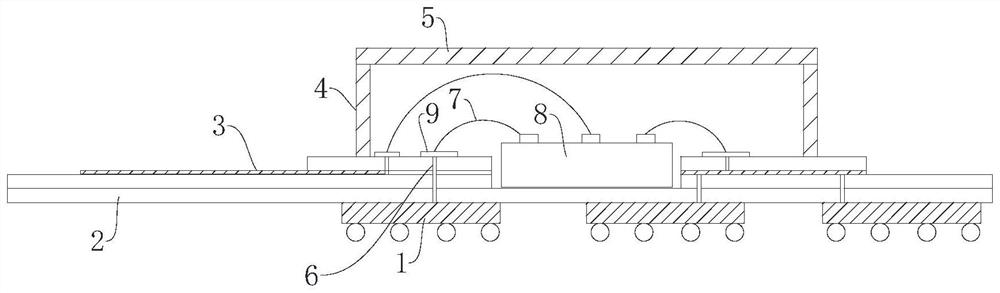

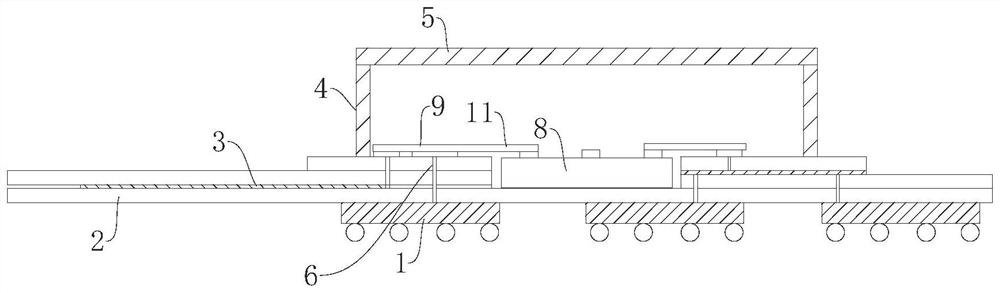

[0064] like figure 2 and image 3 As shown, a microwave and millimeter wave chip hermetic packaging structure with a BGA interface includes a substrate BGA ball planting array structure 1, and an airtight substrate 2 composed of several layers of circuit substrates is arranged on the substrate BGA ball planting array structure 1. The dense substrate 2 is provided with a groove for setting the chip component 8, the chip component 8 is arranged in the groove and bonded with the substrate BGA ball planting array structure 1; the airtight substrate 2 is provided with a surrounding frame 4 around the chip component 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com