Deepwater long and large trestle structure design method

A technology for structural design and trestle bridges, which is applied in the field of structural design of long trestle bridges in deep water. It can solve the problems of inconvenient steel pipe pile bending stability checking and the inability to directly calculate the calculation length of steel pipe piles, so as to achieve accurate and reliable calculation results and reduce labor costs. The effect of processing workload and high model accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

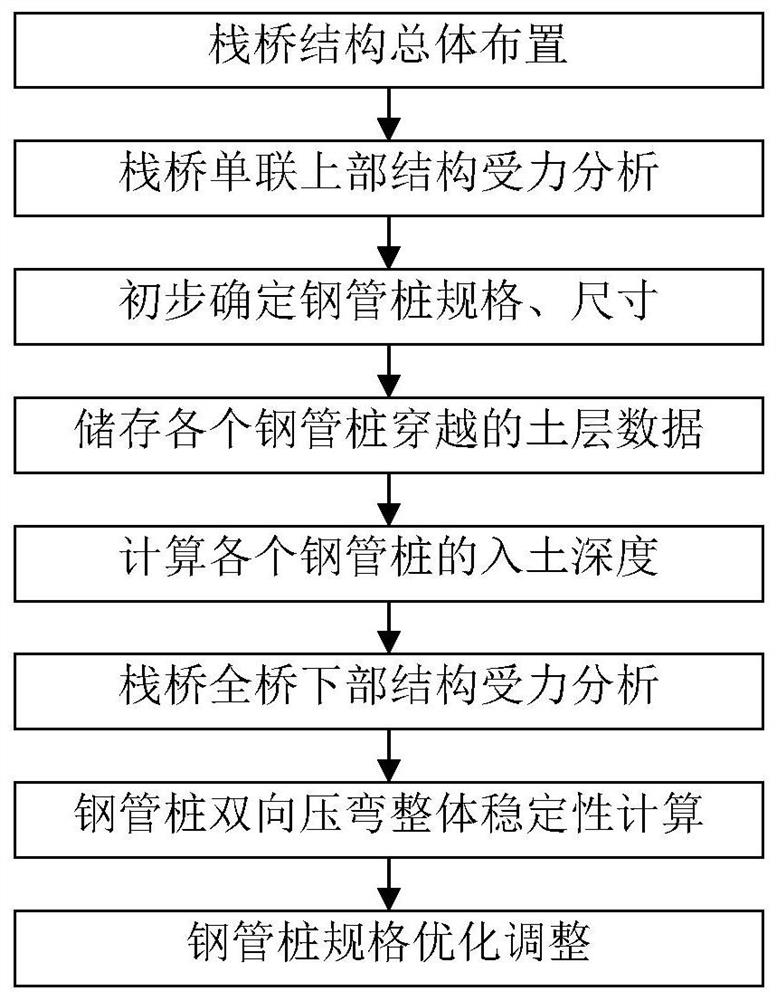

[0054] like figure 1 As shown, a kind of deep-water long trestle structure design method is disclosed in this implementation, comprising the following steps:

[0055] Step 1: Carry out the overall layout of the trestle bridge, where the width of the trestle bridge is the maximum unfolded width of the tracked vehicles to pass plus the safety distance, the standard span of the trestle bridge ranges from 12m to 15m, and the single trestle section consists of 4 Composed of ~6 standard spans, the elevation of the single trestle section is symmetrically arranged, the trestle may include a curved trestle section, and the plane of the curved trestle section is arranged according to a broken line;

[0056] Step 2: Select any single-connected trestle section, use Midas Civil to establish the finite element model of the superstructure of the single-connected trestle section, apply the load of the superstructure, carry out the moving load analysis, static analysis and buckling analysis of...

Embodiment 2

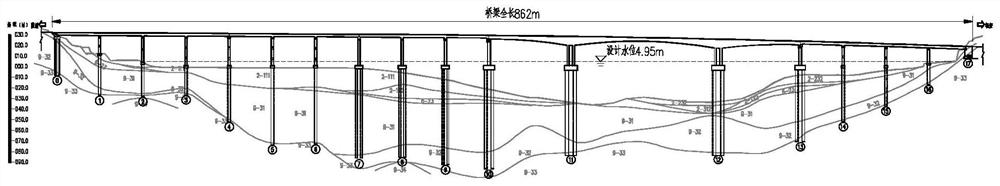

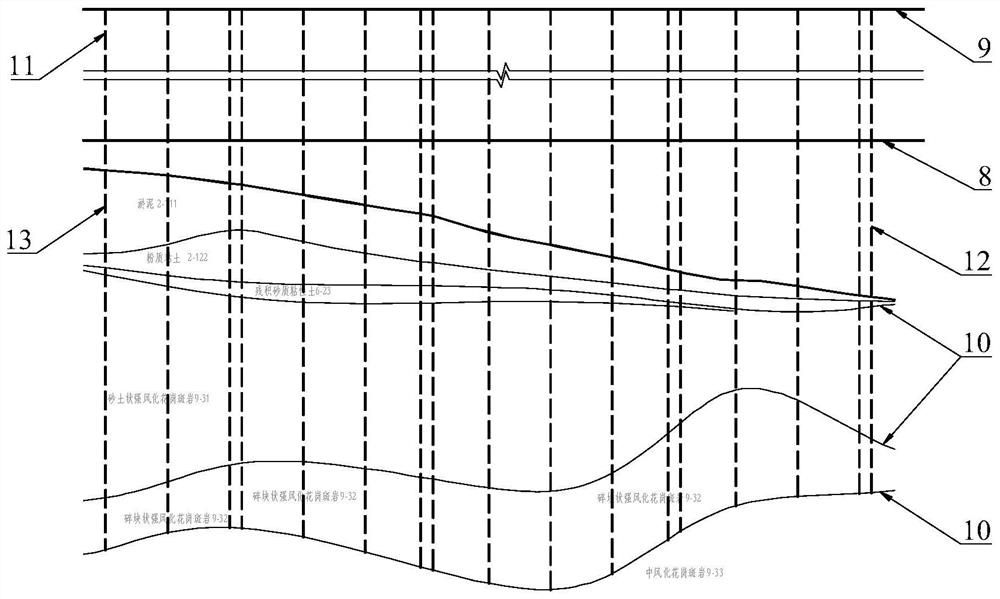

[0065] like figure 2 As shown, a large bridge across the bay has a total length of 862.0m, the plane part is a straight line, and the part is a curve with a radius of 1800m. 41.0m, the theoretical minimum tidal level is -3.58m, and the design flow velocity is 2.3m / s. The bridge pile foundation mainly passes through silt, silty clay, coarse sand, pebbles, residual sandy cohesive soil, and sandy soil-like strongly weathered granite porphyry 7 types of soil layers including , fragmented strongly weathered granite porphyry. In order to facilitate the construction of the bridge foundation cap and the cross-strait traffic, a temporary trestle bridge needs to be designed and built.

[0066] Due to the large water depth, rapid flow velocity and high tidal range at the bridge site, and the influence of typhoon, the stress situation is extremely complicated. There are many factors to be considered in the design of the temporary trestle structure, especially the design of the substruct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com