Method for separating oleuropein from olive leaves through counter-current chromatographic continuous sampling

A technology of countercurrent chromatography and olive leaves is applied in the field of natural product separation and separation of oleuropein in olive leaves, and can solve the problems of low recovery rate, limited injection volume of preparative instruments, and only oleuropein yield. Improves injection volume and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

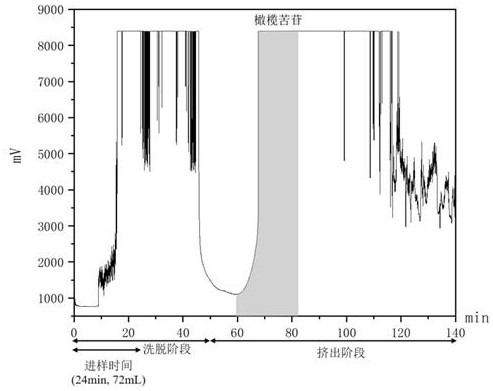

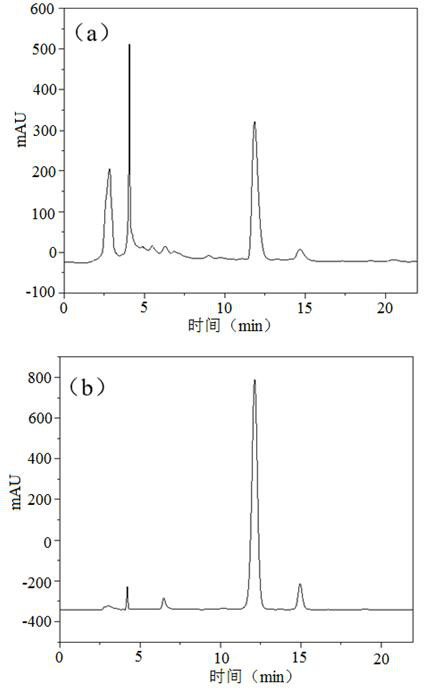

[0024] Take 100 g of dried olive leaves, add 1000 mL of ethanol aqueous solution, the ethanol aqueous solution is composed of 800 mL of ethanol and 200 mL of water; extract under reflux for 90 min, filter to obtain an extract, and place the extract at a temperature of 55°C and a pressure of -0.08MPa. Concentrate under reduced pressure to solvent-free state under reduced pressure to obtain crude extract of olive leaf. Mix n-butanol, ethyl acetate, methanol, water, and dichloromethane in a volume ratio of 1:19:1:19, shake, stand for layering, and obtain a two-phase solvent system. The original mobile phase was used as the original mobile phase for countercurrent chromatographic separation; then the original mobile phase was divided into two parts; 50 mg of olive leaf crude extract was dissolved in a part of the original mobile phase (100 mL) to prepare a mass-volume concentration of 5 mg / mL. sample solution, another part of the original mobile phase is the mobile phase, and the ...

Embodiment 2

[0030]Take 50 g of dried olive leaves, add 500 g of water, heat under reflux for 120 min, and filter to obtain an extract. The extract is dried under reduced pressure at a temperature of 75 °C and a pressure of -0.08 MPa to obtain crude olive leaf extract. Mix n-butanol, ethyl acetate, methanol, and water in a volume ratio of 1:19:1:19, shake, stand for layering, and obtain a two-phase solvent system; the upper phase of the two-phase solvent system is used as a countercurrent chromatograph Separated stationary phase, the lower phase of this two-phase solvent system was used as the original mobile phase for countercurrent chromatography; then the original mobile phase was divided into two parts; 700 mg of olive leaf crude extract was dissolved in a part of the original mobile phase (70 mL) , to prepare a sample solution with a mass volume concentration of 10 mg / mL; another part of the original mobile phase is the mobile phase; the sample solution is filtered with a 0.45 μm Milli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com