Large-area patterned micro-nano particle self-assembly structure and preparation method thereof

A micro-nano particle and patterning technology, applied in the directions of micro-structure technology, micro-structure device, manufacturing micro-structure device, etc., can solve the problem that the preparation method of patterned micro-nano particles needs to be improved, complicated, and the pulling/convective self-assembly is slow to prepare. speed etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

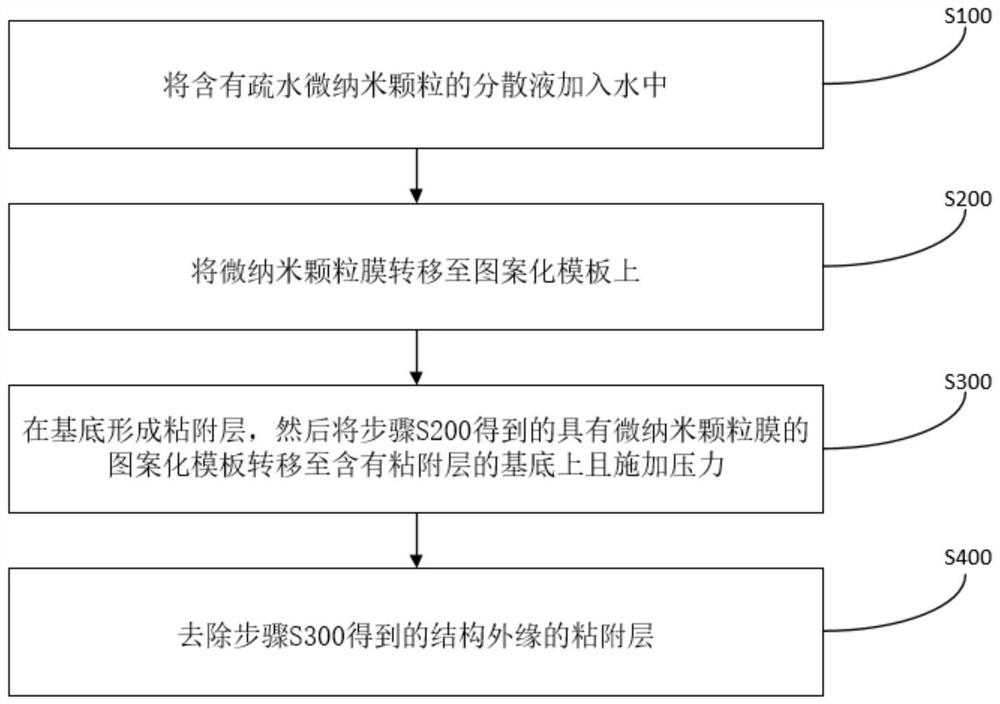

[0053] Step 1: Add the colloidal dispersion liquid containing 900nm silicon dioxide hydrophobic nanoparticles into the liquid pool containing deionized water dropwise. Single-layer micro-nanoparticle film with closely arranged area;

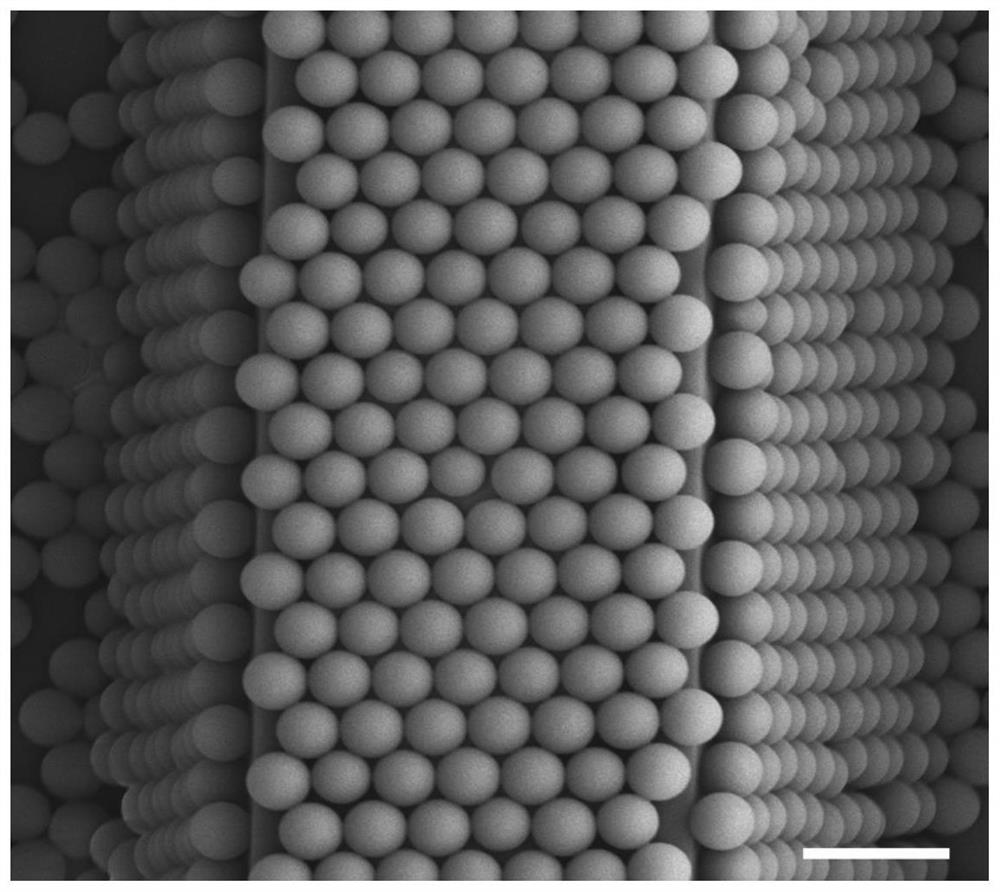

[0054] Step 2: Prepare a template with a striped pattern using microimprinting technology, in which the width of the striped protrusions is 6 μm, and the interval between two adjacent stripes is 14 μm, and then the silicon dioxide hydrophobic nanoparticle film obtained in step 1 is transferred to On a template with a striped pattern (such as figure 2 shown);

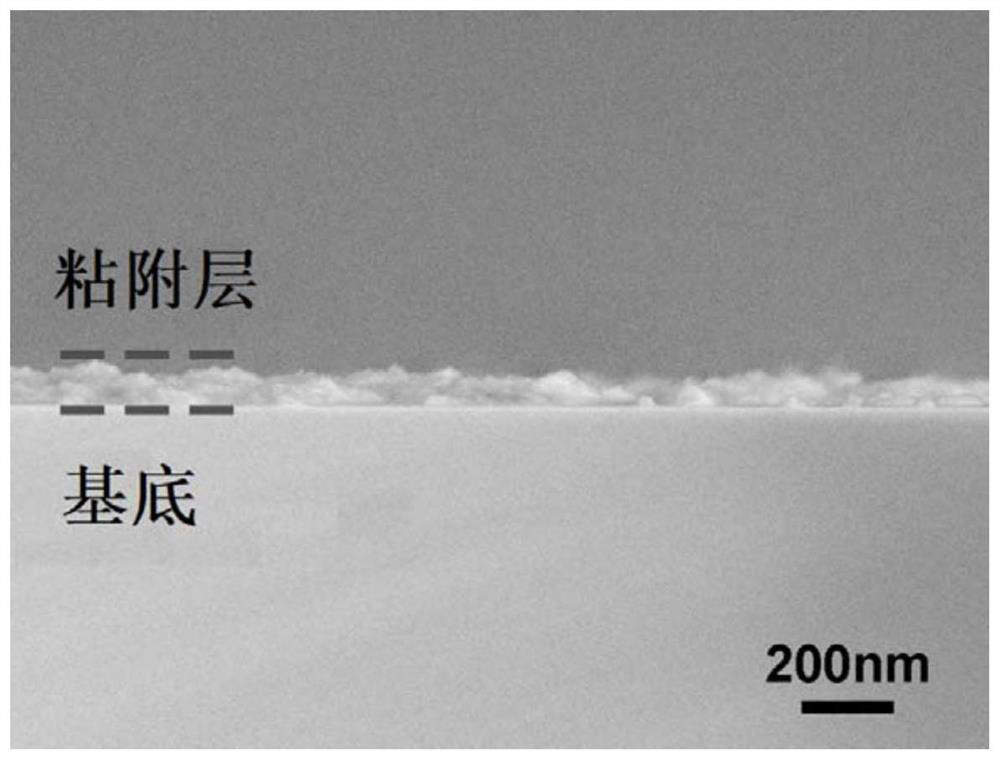

[0055] Step 3: Utilize the modified silane polymer to prepare an adhesion layer (such as image 3 shown), and then the surface is covered with a striped pattern of silicon dioxide hydrophobic nanoparticle film and pressed against the surface of the silicon wafer containing the adhesive layer (such as Figure 4 shown);

[0056] Step 4: Use oxygen reactive ion etching to remove the adhes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com