Multifunctional rotary operation tool applied to deep sea ROV

A working tool and multi-functional technology, which can be used in underwater operation equipment, transportation and packaging, ships, etc. It can solve the problems of difficult design of dynamic seals and end-face seals, environmental pollution, and unreliable seals. The effect of operation, strong scalability, and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

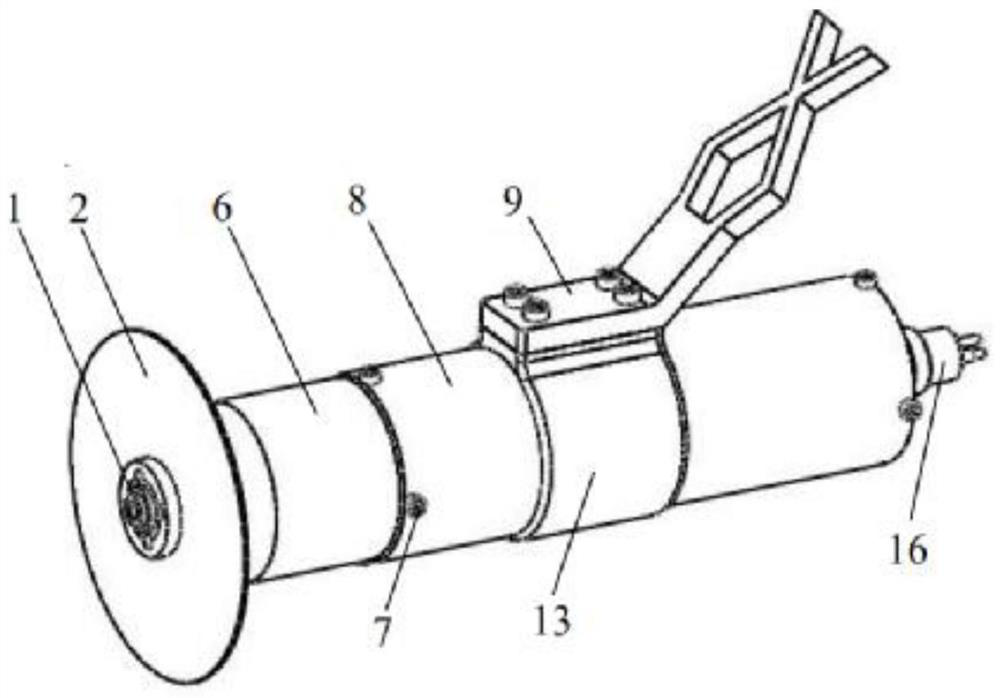

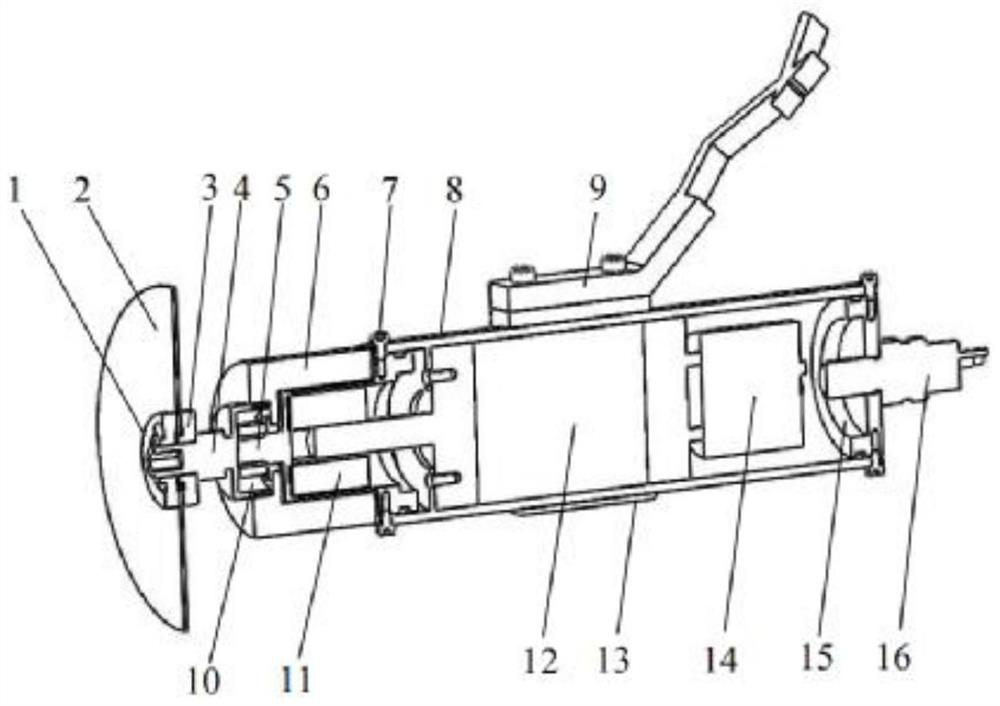

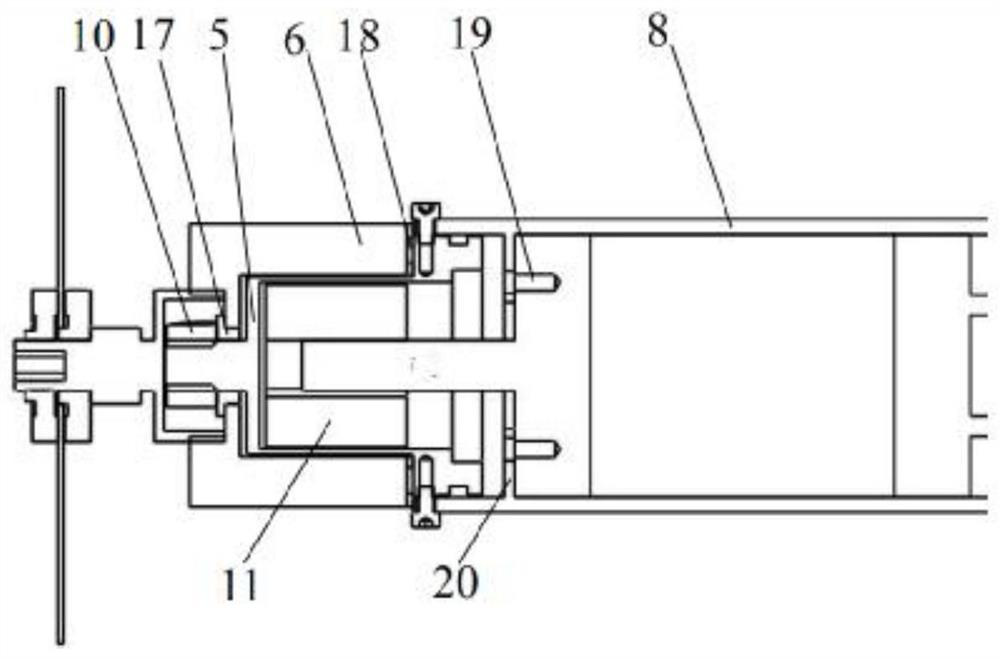

[0049] see Figure 1-15 , a multifunctional rotary operation tool applied to deep-sea ROVs, including a sealing cylinder 8, a rib plate 20 is fixedly installed inside the sealing cylinder 8, and the rib plate 20 is fixedly connected with a brushless motor 12 through a second fixing bolt 19; Under the action of the rib plate 20 and the second fixing bolt 19, the brushless motor 12 can be installed stably, thereby ensuring the use effect of the brushless motor 12 and having strong practicability; the input end of the brushless motor 12 is connected with a motor driver 14, The protruding shaft of the brushless motor 12 is fixedly connected with the inner rotor 11 through the jackscrew, and under the action of the motor driver 14, the brushless motor 12 can be driven to make a circular motion, so that the protruding shaft of the brushless motor 12 can drive the inner rotor 11 Rotation; the outer wall of the inner rotor 11 is sleeved with an isolation cover 5, the right end of the ...

Embodiment 2

[0058] Compared with Embodiment 1, this embodiment differs in that the connecting device at the left end of the outer rotor 6 is different, and the rest of the structures are the same. Such as Figure 16 As shown, in this embodiment, a cutting saw is detachably connected to the left end of the outer rotor 6 .

[0059] Working principle: the right end of the isolation cover 5 is embedded in the left end of the sealing cylinder 8, and they are in clearance fit with each other, and a static seal is formed through the O-ring, and the left end of the sealing cylinder back cover 15 is embedded in the right end of the sealing cylinder 8, and they are in a gap with each other Cooperate, form a static seal through the O-ring, convert the dynamic seal into a static seal, and achieve zero leakage, thereby further improving the actual use effect. The inner rotor 11 is separated from the outer rotor 6 under the action of the isolation cover 5 , the non-contact power transmission between t...

Embodiment 3

[0061] Compared with Embodiment 1 and Embodiment 2, this embodiment differs in that the connecting device at the left end of the outer rotor 6 is different, and the rest of the structures are the same. Such as Figure 17 As shown, in this embodiment, a drill bit is detachably connected to the left end of the outer rotor 6 .

[0062] Working principle: the right end of the isolation cover 5 is embedded in the left end of the sealing cylinder 8, and they are in clearance fit with each other, and a static seal is formed through the O-ring, and the left end of the sealing cylinder back cover 15 is embedded in the right end of the sealing cylinder 8, and they are in a gap with each other Cooperate, form a static seal through the O-ring, convert the dynamic seal into a static seal, and achieve zero leakage, thereby further improving the actual use effect. The inner rotor 11 is separated from the outer rotor 6 under the action of the isolation cover 5 , the non-contact power transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com