Stone crystal composite floor and preparation method thereof

A composite flooring, selected technology, applied in the field of floor boards, can solve problems such as arching and shrinkage joints, and achieve the effects of inhibiting expansion, high comfort, and improving dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

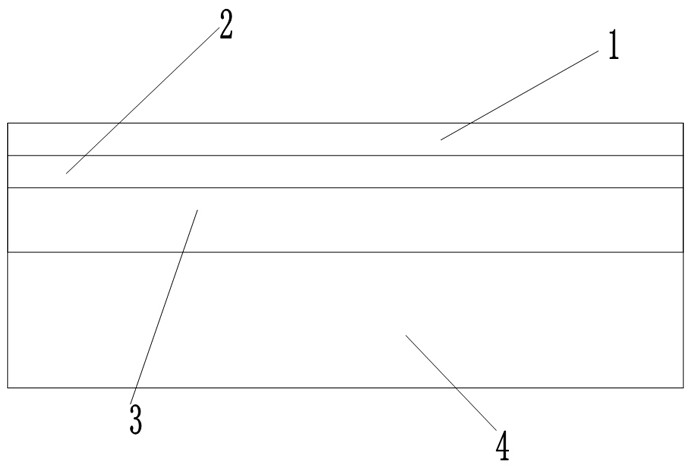

[0038] A stone-crystal composite floor, comprising a wear-resistant layer 1, a color film layer 2, a PVC-impregnated glass fiber layer 3, and a substrate layer 4 arranged sequentially from top to bottom; the thickness of the PVC-impregnated glass fiber layer 3 is 0.10mm . The wear-resistant layer 1 is a PMMA film.

[0039] The base layer 4 is made of the following raw materials in parts by weight: 200 parts of filler, 50 parts of PVC resin, 2 parts of internal lubricant, 1.5 parts of external lubricant and 10 parts of stabilizer.

[0040] In this example, the added CPE resin is partially chlorinated high-density polyethylene with a chlorine content of 25% to 35%. CPE resin has the advantages of economical price and good processability, and can be used as an impact modifier for CPVC In the process of processing; compared with PVC, due to the increase of chlorine content, the intermolecular polarity and brittleness of CPVC increase, so a certain amount of impact modifier needs ...

Embodiment 2

[0052] A stone-crystal composite floor, comprising a wear-resistant layer 1, a color film layer 2, a PVC-impregnated glass fiber layer 3, and a substrate layer 4 arranged sequentially from top to bottom; the thickness of the PVC-impregnated glass fiber layer 3 is 0.10mm , the wear-resistant layer 1 is a PMMA film.

[0053] The base layer 4 is made of the following raw materials in parts by weight: 150 parts of filler, 25 parts of PVC resin, 1 part of internal lubricant, 1 part of external lubricant and 5 parts of stabilizer, 10 parts of CPVC resin and 1 part of CPE resin .

[0054] The filler is glass fiber powder with a length of 5-25 μm and an aspect ratio of about 5-10.

[0055] Described PVC is PVC SG-5 type.

[0056] The internal lubricant is G60.

[0057] Described external lubricant is PE wax.

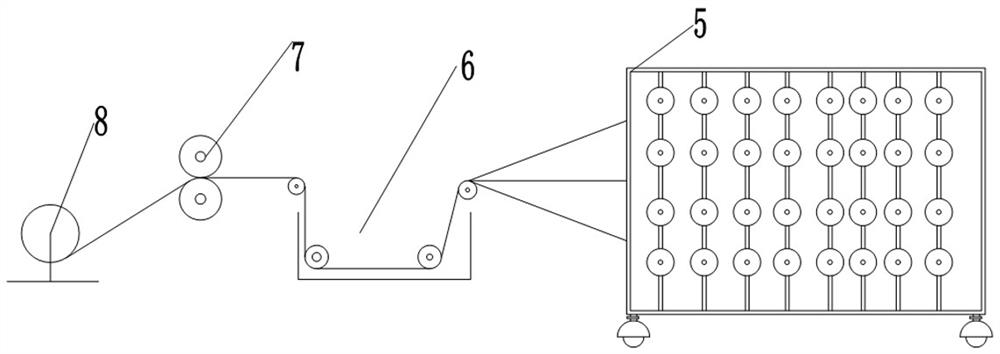

[0058] A preparation method for a stone crystal composite floor, comprising the following steps:

[0059] S1: Preparation of substrate layer 4: Weigh 150 parts of filler, 2...

Embodiment 3

[0063] A stone-crystal composite floor, comprising a wear-resistant layer 1, a color film layer 2, a PVC-impregnated glass fiber layer 3, and a substrate layer 4 arranged sequentially from top to bottom; the wear-resistant layer 1 is a PMMA film, and the The thickness of the PVC-impregnated glass fiber layer 3 is 0.10mm.

[0064] The base layer 4 is made of the following raw materials in parts by weight: 175 parts of filler, 38 parts of PVC resin, 0.95 parts of internal lubricant, 0.83 parts of external lubricant, 7.01 parts of stabilizer, 12 parts of CPVC resin and 2.67 parts of CPE resin .

[0065] The filler is glass fiber powder with a length of 5-25 μm and an aspect ratio of about 5-10.

[0066] Described PVC is PVC SG-5 type.

[0067] The internal lubricant is G60.

[0068] Described external lubricant is PE wax.

[0069] A preparation method for a stone crystal composite floor, comprising the following steps:

[0070] S1: Preparation of substrate layer 4: Weigh 175...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com