Clamping device with adjustable workpiece machining angle

A processing angle and clamping device technology, applied in metal processing, positioning devices, accessory devices, etc., can solve problems such as difficulty in finding adjustment tooling, many types of small workpiece structures, and inability to position and process, so as to avoid secondary clamping, Improve the effective processing rate of the equipment and facilitate the adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

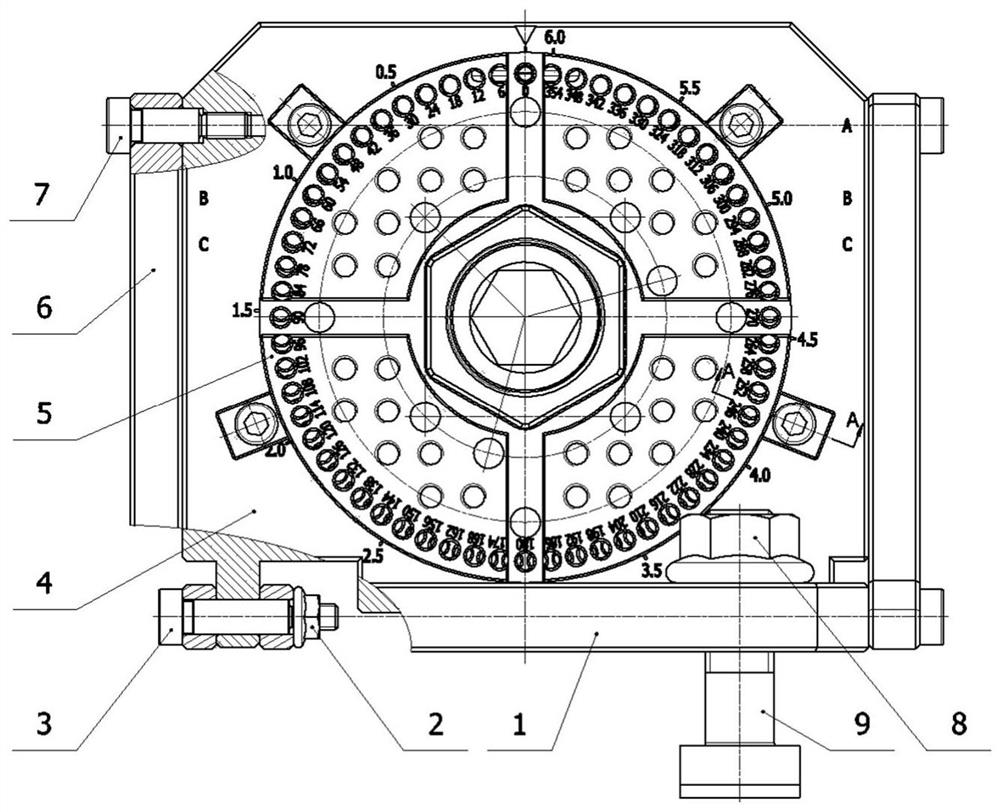

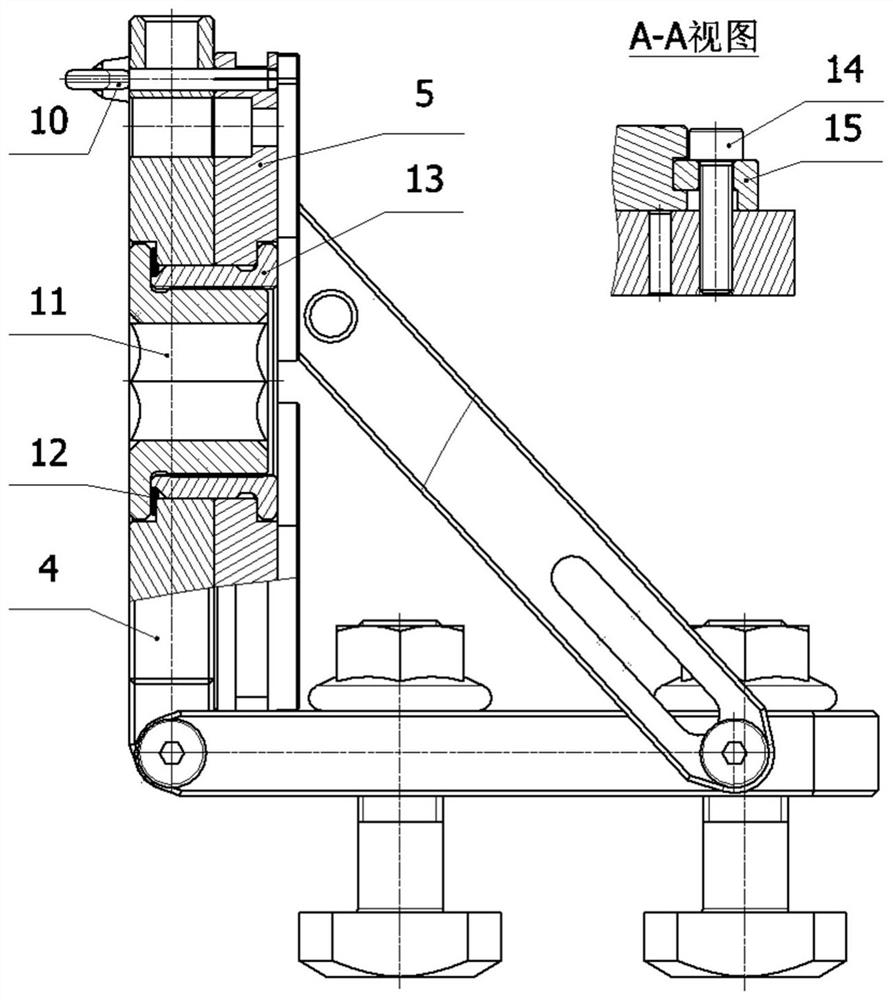

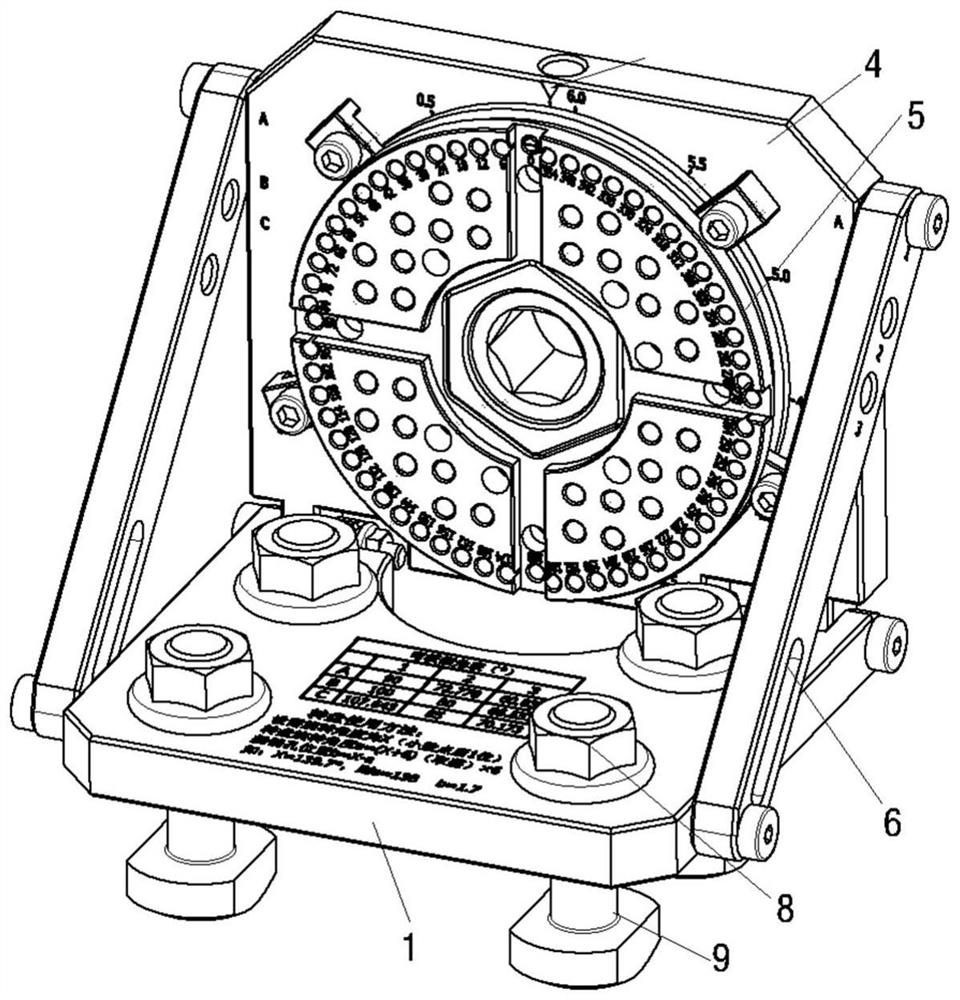

[0031] Such as Figure 1 to Figure 7 As shown, a clamping device with adjustable workpiece processing angle includes a bottom plate 1 and a back plate 4, one end of the back plate 4 is rotatably connected to one end of the bottom plate 1, and the back plate 4 is provided with a handle that can rotate on the back plate 4. Turntable 5, a plurality of turntable pin holes are uniformly arranged along the circumference on the turntable 5, the total phase angle of the plurality of turntable pin holes is 360°, and a plurality of back plate pin holes are arranged at equal intervals along the circumference on the back plate 4, and the back plate pin holes The number is the same as the number of turntable pin holes, and the phase angle of two adjacent backplane pin holes is smaller than the phase angle of two adjacent turntable pin holes; the backplane pin holes and turntable pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com