Automatic SMD carrier tape adhesive film splicing machine

A technology of splicing machine and carrier tape, which is used in thin material processing, strip winding, transportation and packaging, etc., can solve the problems of low parallel connection efficiency, high labor cost, and parallel connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The present invention is further described below in conjunction with accompanying drawing and embodiment:

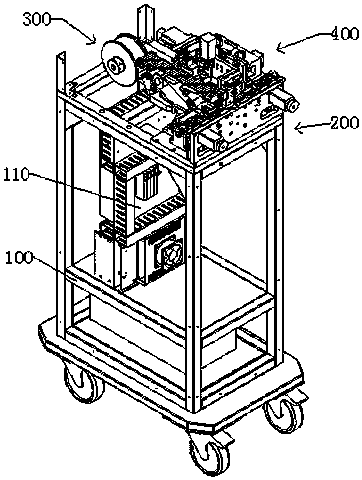

[0086] Such as figure 1 As shown, a kind of automatic SMD carrier tape adhesive film splicing machine includes a frame 100, a cam system 200, a film transfer mechanism 300 and a vacuum film transfer mechanism 400 are arranged above the frame 100, and the frame 100 is equipped with a The motion controller 111 and the motion controller 11 are respectively connected to the cam system 200 , the parallel film transfer mechanism 300 and the vacuum suction film transfer mechanism 400 .

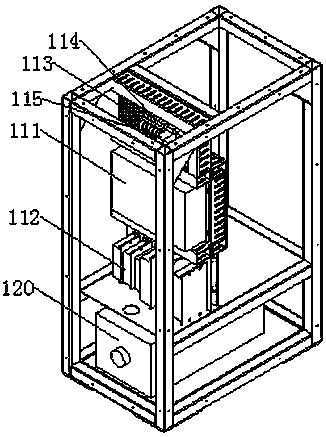

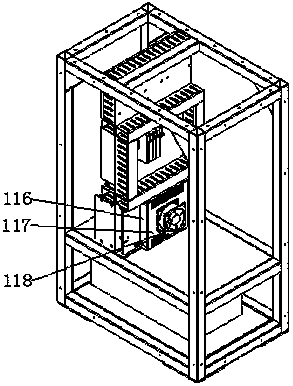

[0087] Such as Figure 2-3 As shown, the frame 100 includes upper and lower layers, and the motion controller 111 is placed on the upper layer, and the motion controller 111 is connected with the motor driver 112 and the integrated industrial control host 116. The motion controller 111 is installed on the electrical installation board 110, and the integrated industrial control host A p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com