Production line information transmission processing method, automatic detection system and equipment

A technology of automatic detection and equipment, applied in the field of electronic information, can solve the problems of high labor cost, low quality inspection efficiency, high error rate, and achieve the effect of improving the quality of shipments and the yield of shipments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] like figure 1 As shown, this embodiment provides a method for transmitting and processing production line information, including the following steps:

[0020] S1 configures detection parameter information on the server side, where the detection parameter information includes a detection qualified threshold parameter and a detection fault tolerance threshold parameter;

[0021] S2 configures the online product ID code on the server side, and binds the online product ID code with the detection parameter information;

[0022] S3 obtains production line information by using an automated detection device, where the production line information includes the current detection parameters of the online product and the online product ID code of the current product; the automated detection device may be the automated detection device described in Embodiment 3.

[0023] S4 transmits the production line information obtained by the automatic testing equipment to the server through th...

Embodiment 2

[0029] like figure 2 As shown, this embodiment provides an automated detection system, including:

[0030] The server is used to configure the detection parameter information according to the external input information, receive and process the production line information sent by the automatic detection equipment, and generate return information according to the processing result;

[0031] Automated testing equipment, used to detect online products to obtain production line information; the production line information includes the current testing parameters of the online product and the online product ID code of the current product; the automated testing equipment can be the one described in Embodiment 3 of automated testing equipment.

[0032] The transmission network is used to transmit the production line information obtained by the automatic inspection equipment to the server and transmit the return information generated by the server according to the processing result to...

Embodiment 3

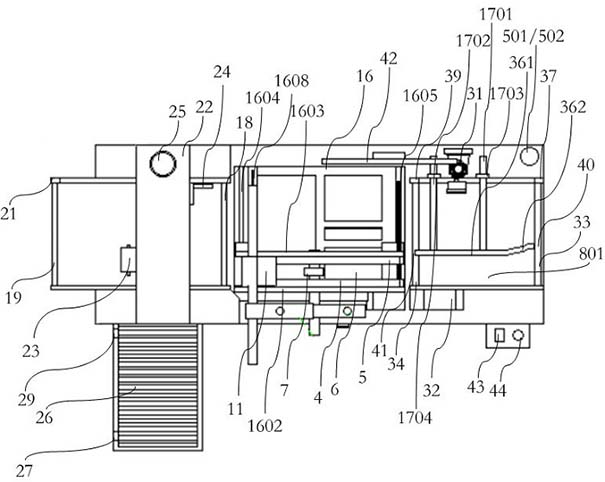

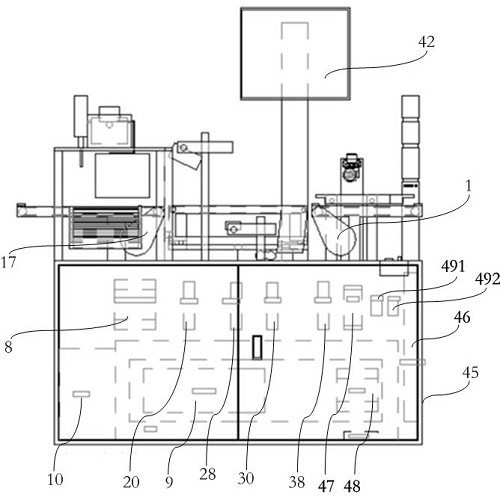

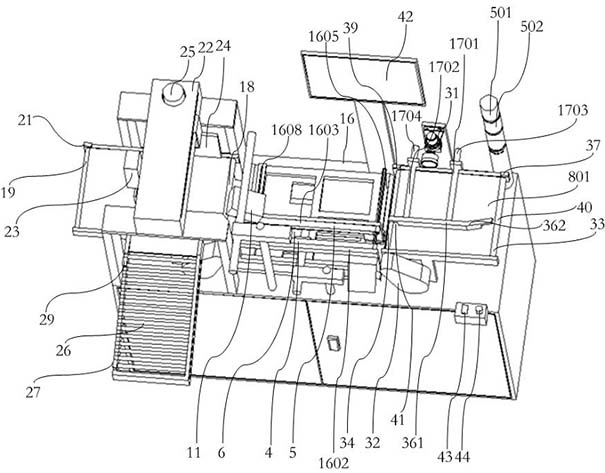

[0035] like Figure 3-7 As shown, this embodiment provides an automatic detection device, including a main support frame of the device, a transmission device provided with a detection conveyor belt, a quality parameter detection device, and an ID code acquisition device provided with an ID code acquisition execution end; the transmission device, quality The parameter detection device and the ID code acquisition device are both arranged on the main support frame of the equipment; the detection execution end and the ID code acquisition execution end are respectively arranged on the top or bottom or side of the detection conveyor belt. Those skilled in the art can understand that the conveying device is used to form an assembly line in conjunction with the upstream production line and the downstream production line, and when the product is transported through the inspection conveyor belt, it is convenient to use the quality parameter detection device and the ID code acquisition de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com