Nitrogen oxide mixing treatment device

A technology of mixed treatment and nitrogen oxides, which is applied in mufflers, exhaust treatment, exhaust devices, etc., can solve the problems of poor catalytic effect, insignificant effect, uneven mixing of ammonia gas, etc., to improve the uniformity of the flow field and anti-urea crystallization ability, improve catalytic reaction efficiency, improve the effect of induction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

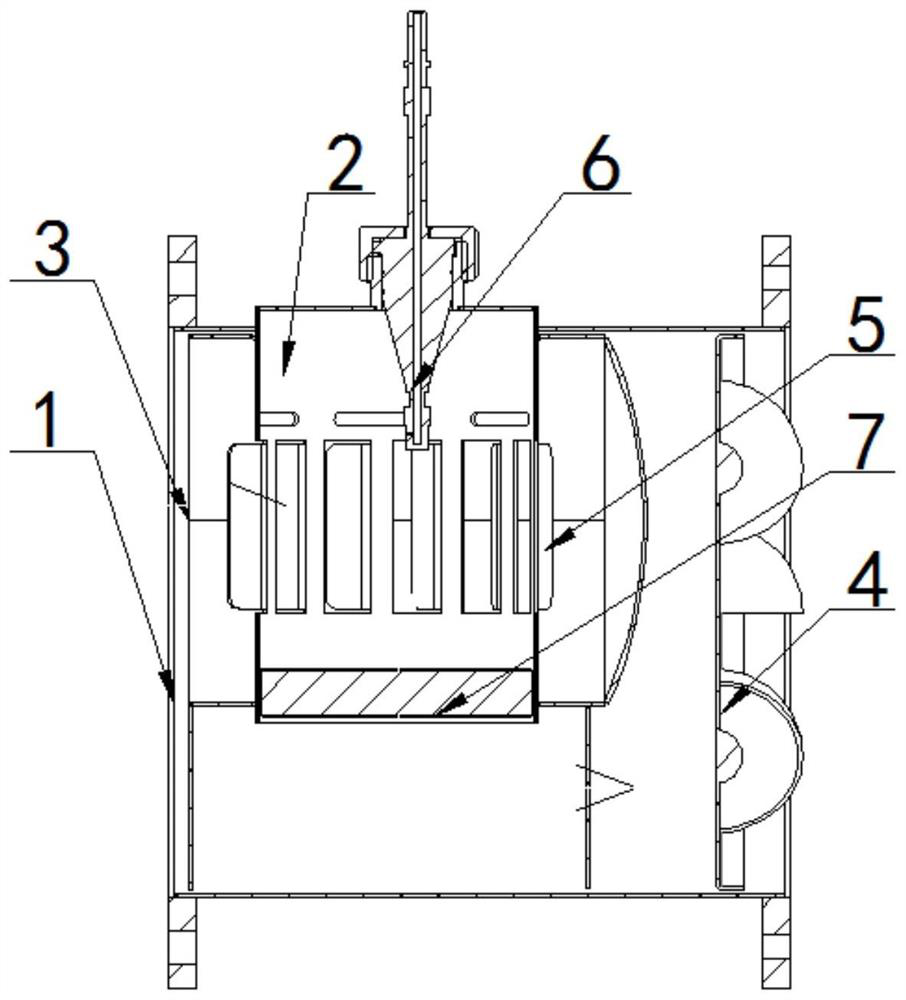

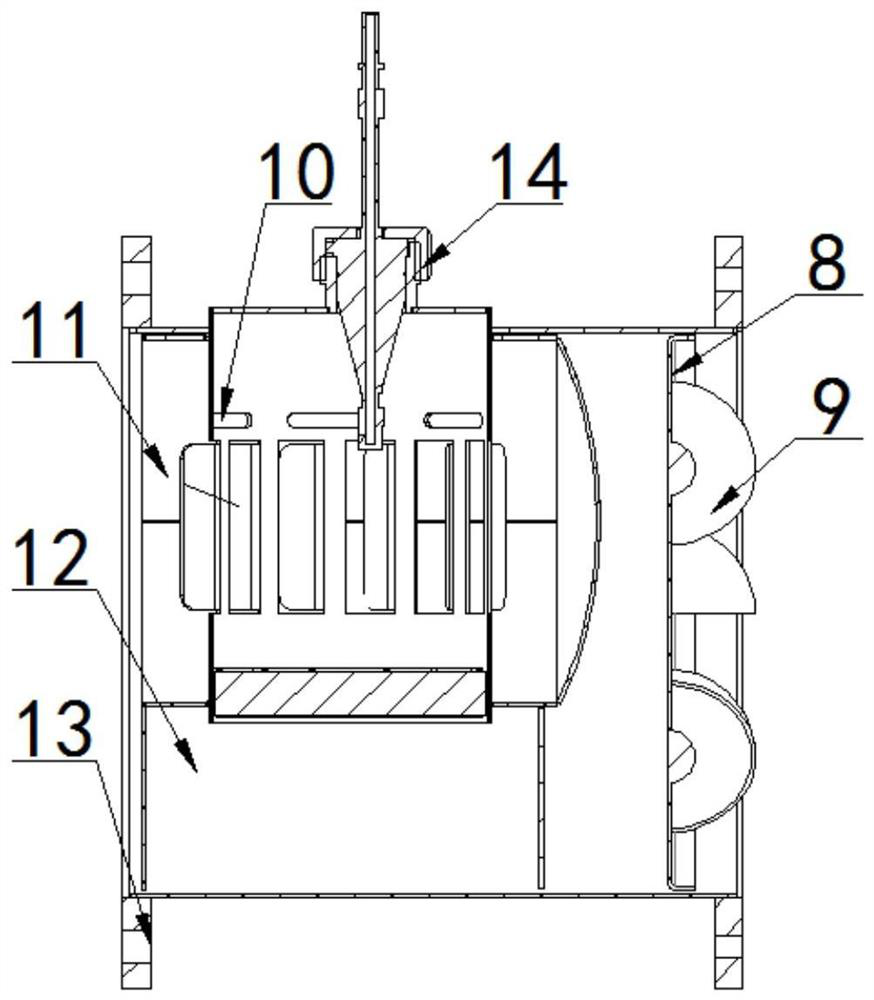

[0023] A nitrogen oxide mixing treatment device, comprising: a hollow outer casing 1 and a mixer 2 arranged in the outer casing 1; an air inlet 3 is provided on the outer casing 1 relatively close to the mixer 2, so The end of the outer casing 1 relatively far away from the mixer 2 is provided with a cyclone structure 4, and the cyclone structure 4 is used for uniform gas and flow diversion;

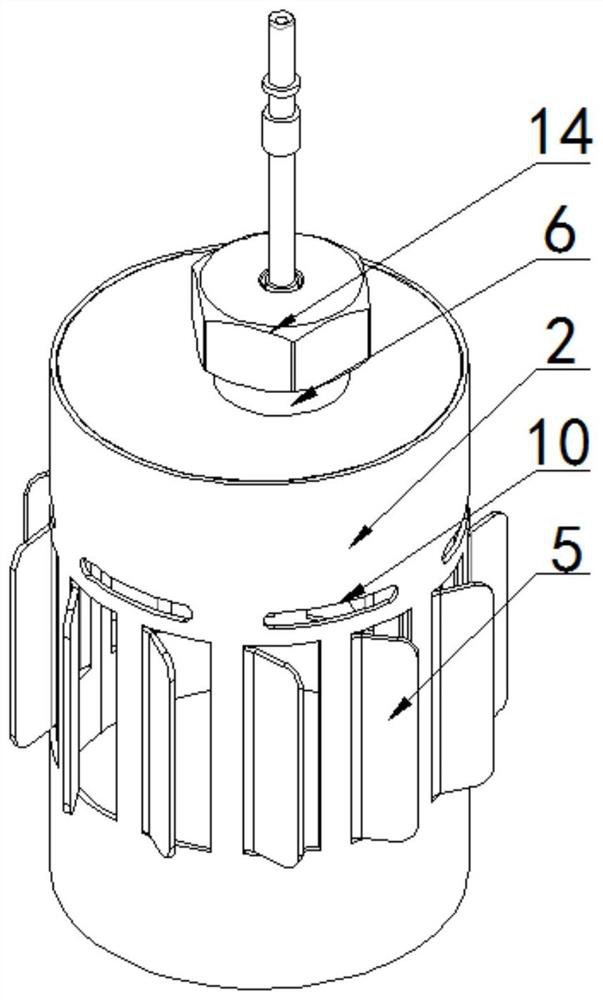

[0024] The interior of the mixer 2 is hollow, and the side wall of the mixer 2 is provided with several spaced first through holes, and the edge of the first through holes is provided with a guide plate 5 facing the inner wall of the outer casing 1; The upper end of the outer casing 1 is vertically provided with a through nozzle 6 , which faces the interior of the mixer 2 and is used for injecting reactants; the inner lower end of the mixer 2 is provided with a filter screen 7 for decomposing gas particles.

[0025] When using this device, if figure 1 As shown, firstly, the automobile e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com