Method for recovering valuable metals in carbon black

A recovery method and carbon black technology, applied in chemical instruments and methods, inorganic chemistry, vanadium compounds, etc., can solve the problems of high cost, low metal recovery rate, and difficulty in metal recovery, avoiding pollution and solving single-variety problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

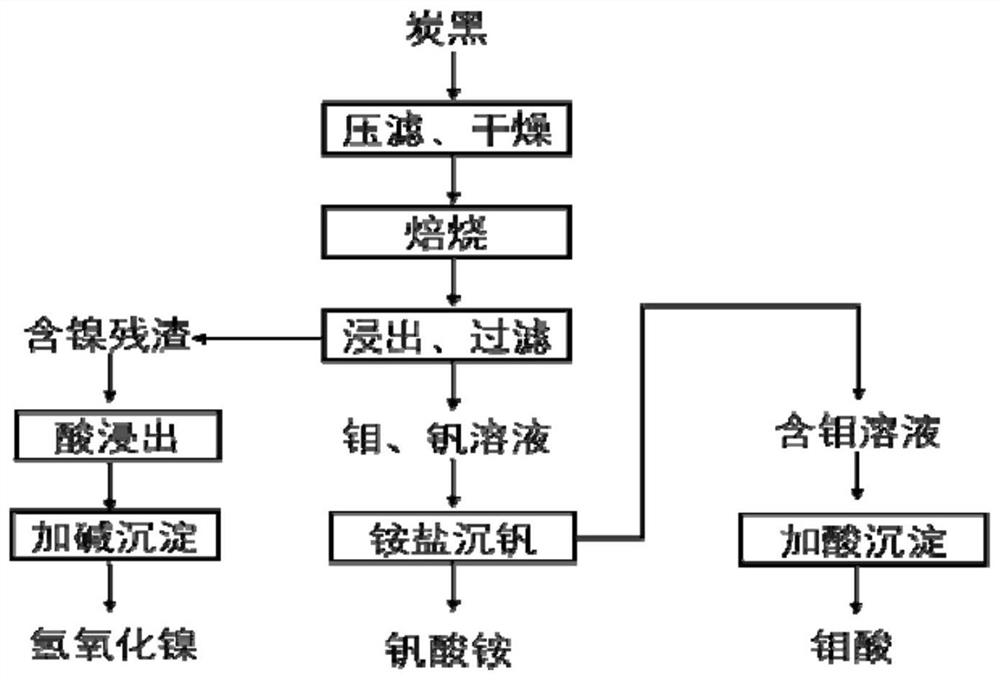

[0020] like figure 1 Shown, a kind of recovery method of valuable metal in carbon black comprises the steps:

[0021] 1) Water-containing carbon black is press-filtered, heated and dehydrated to a water content of 5%;

[0022] 2) Calcining the carbon black at 600° C. for 4 hours to remove flammable impurities such as carbon and sulfur in the carbon black to obtain ash rich in metallic nickel, vanadium and molybdenum;

[0023] 3) adding sodium hydroxide solution and stirring and leaching, the leaching temperature is 80°C, the leaching time is 3h, after washing and filtering, a solution containing molybdenum and vanadium and a nickel-containing residue are obtained;

[0024] 4) Add sulfuric acid to the nickel-containing residue to dissolve and leach the nickel, the leaching temperature is 85°C, and the leaching time is 2.5h; after leaching, filter, add sodium hydroxide to the filtrate to adjust the solution pH to 9.0, and the nickel Form precipitation, precipitation temperatur...

Embodiment 2

[0029] like figure 1 Shown, a kind of recovery method of valuable metal in carbon black comprises the steps:

[0030] 1) Water-containing carbon black is press-filtered, heated and dehydrated to a moisture content of 1.5%;

[0031] 2) Mix the dehydrated carbon black and sodium carbonate uniformly at a ratio of 1:1, roast at 550°C for 4 hours, remove flammable carbon, sulfur and other impurities in the carbon black, and obtain ash rich in metal nickel, vanadium and molybdenum;

[0032] 3) add water and stir for leaching, the leaching temperature is 85°C, the leaching time is 3h, after washing and filtering, a solution containing molybdenum and vanadium and a nickel-containing residue are obtained;

[0033] 4) Add sulfuric acid to the nickel-containing residue to dissolve and leach the nickel. The leaching temperature is 80°C, and the leaching time is 3 hours; Precipitation, precipitation temperature 50°C, precipitation time 2.5h;

Embodiment 3

[0038] like figure 1 Shown, a kind of recovery method of valuable metal in carbon black comprises the steps:

[0039] 1) Water-containing carbon black is press-filtered, heated and dehydrated to a moisture content of 2.0%;

[0040] 2) Mix the dehydrated carbon black and sodium carbonate uniformly at a ratio of 1:0.5, roast at 700°C for 3 hours, remove flammable carbon, sulfur and other impurities in the carbon black, and obtain ash rich in metal nickel, vanadium and molybdenum;

[0041] 3) add water and stir for leaching, the leaching temperature is 85°C, the leaching time is 3h, after washing and filtering, a solution containing molybdenum and vanadium and a nickel-containing residue are obtained;

[0042] 4) Add sulfuric acid to the nickel-containing residue to dissolve and leach the nickel. The leaching temperature is 80°C, and the leaching time is 3 hours; Precipitation, precipitation temperature 50°C, precipitation time 2.5h;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com