Gluing method for battery cell

A cell and rubber strip technology, applied in circuits, electrical components, assembling battery machines, etc., can solve the problems of easy falling off, weak bonding between cells and cells, and achieve the effect of firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for applying glue on an electric core, comprising

[0038] S1. Determine the glue area on the battery cell;

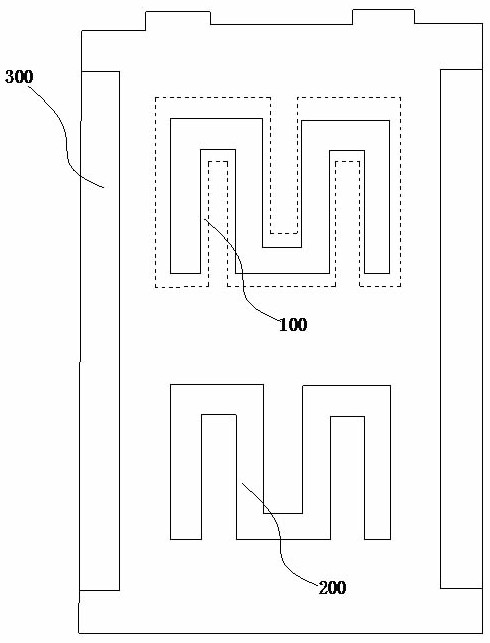

[0039] S2, apply glue according to the preset track to form a glue strip 200, and the glue strip 200 is a square waveform;

[0040] S3, pressing the adjacent cells tightly;

[0041] S4. Complete the fixing and bonding of all battery cells.

Embodiment 2

[0043] A method for applying glue on an electric core, comprising

[0044] S1. Determine the glue area on the battery cell;

[0045] S2. Apply glue according to the preset track to form a glue strip 200, which is a sinusoidal waveform;

[0046] S3, pressing the adjacent cells tightly;

[0047] S4. Complete the fixing and bonding of all battery cells.

[0048] In this way, the gluing method on the battery cell is to determine the gluing area 100 on the battery cell, and then apply glue to form a gluing strip 200 according to a preset track, for example, a square waveform or a sinusoidal waveform, to tightly press adjacent cells, Complete the gluing work, avoid the formation of multiple glue blank areas at the joint of the two cells, make the bonding between the cells more firm, and enable the battery box to work safely and normally.

[0049] In one of the embodiments, in order to control the amount of glue applied, before S1, the area of the glued surface of the battery ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com