In-situ testing device and method for friction and wear of material under high-temperature prestress loading

A friction and wear, prestressing technology, applied in the direction of measuring devices, analyzing materials, testing wear resistance, etc., can solve the problems of low heating rate, unfavorable modular integration, complex structure, etc., to save energy, reduce heat spread, ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

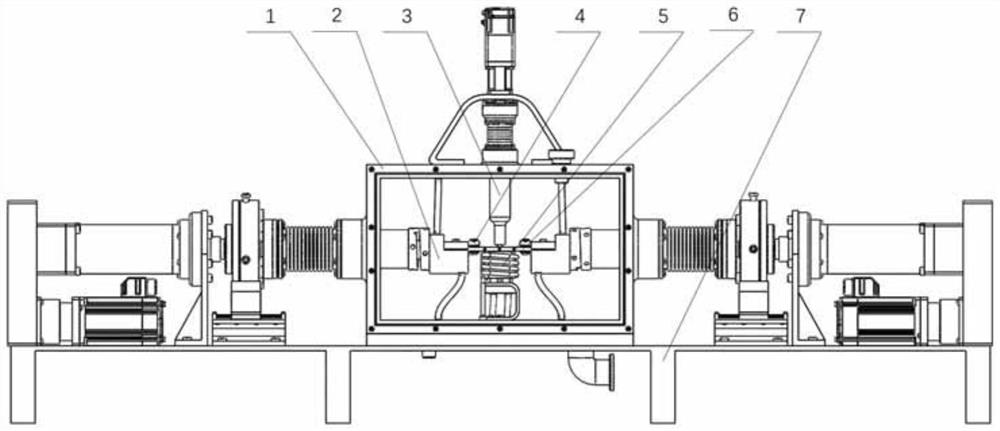

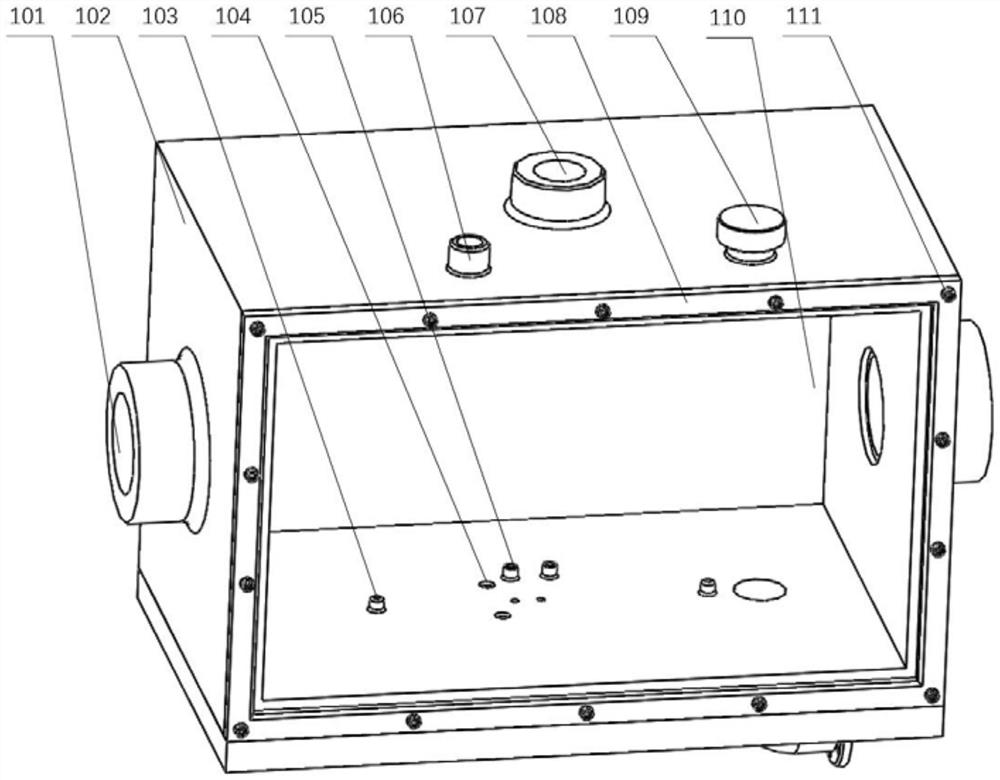

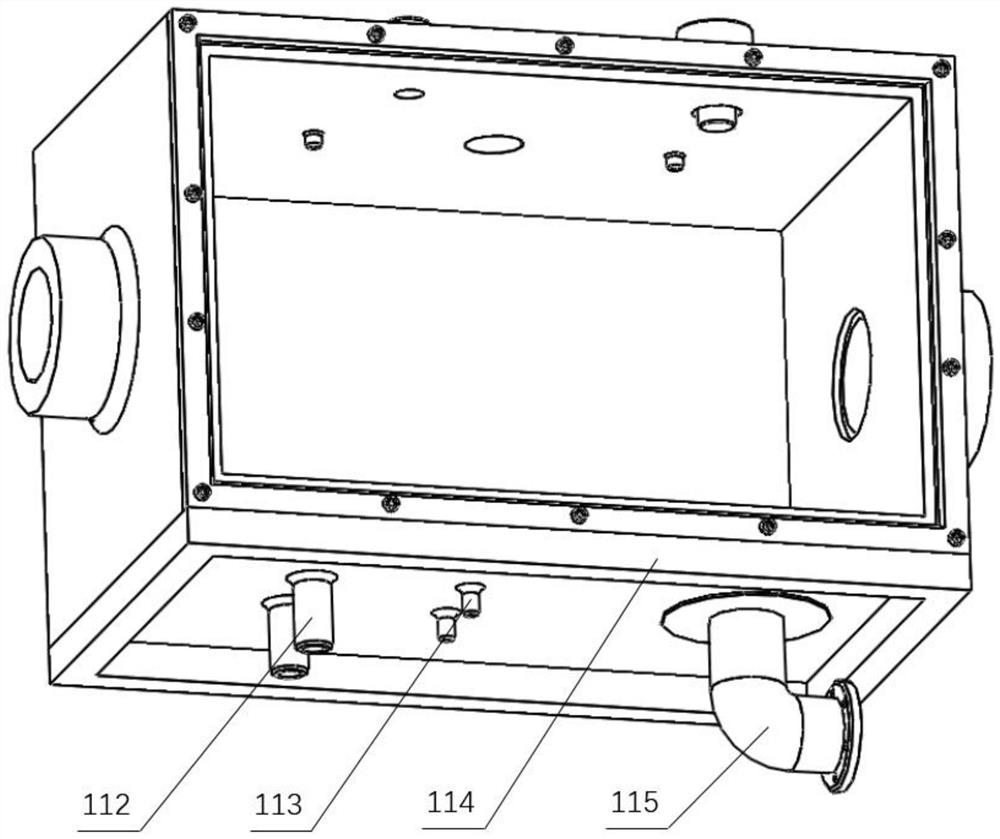

[0036] see figure 1 , including test chamber 1, prestress loading and driving module 2, friction load loading module 3, acoustic emission in-situ monitoring module 4, high temperature loading module 5, friction specimen 6 and frame 7, wherein: the top of frame 7 The middle part is fixedly connected to the test chamber 1, and the prestressed loading and driving modules 2 symmetrically arranged on both sides penetrate the test chamber 1 horizontally and are fixedly connected to the top of the frame 7. The prestressed loading and driving modules 2 are fixed by the clamp 214 Connect the friction test piece 6, the acoustic emission in-situ monitoring module 4 is installed on the friction test piece 6, the high temperature loading module 5 is fixed inside the test chamber 1 by bolts and is located under the friction test piece 6, and the friction load loading module 3 penetrates the test The upper surface of the cavity 1 is supported by the support frame 303 and connected with the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com