Downhole tubular column and hydraulic opening tool for opening sliding sleeve switch

A technology of sliding sleeve switch and downhole pipe string, which is applied in the direction of wellbore/well valve device, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems such as difficult sliding sleeve combination, and achieve reliable operation and convenient use , The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

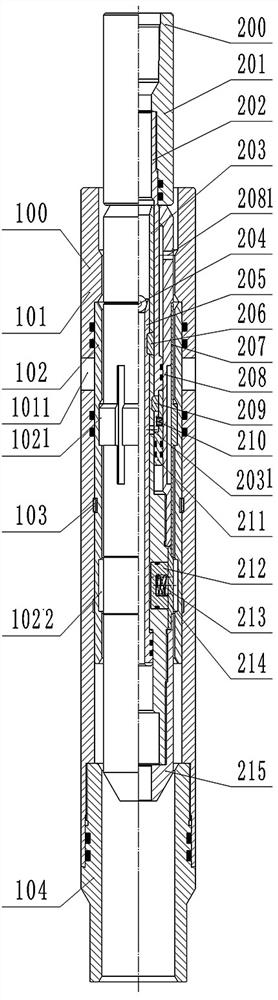

[0058] The downhole string includes the string body, which includes serially connected casings, packers, and sliding sleeve switches. The packer is used to fix the downhole string in the well, and the sliding sleeve switches are connected Corresponding to the production layer, the production of the downhole pipe string is controlled by controlling the opening and closing of the sliding sleeve switch. Under normal circumstances, when the downhole pipe string is run into the well, the sliding sleeve switch is closed. figure 2 The hydraulic opener shown controls the opening of the corresponding slide switch.

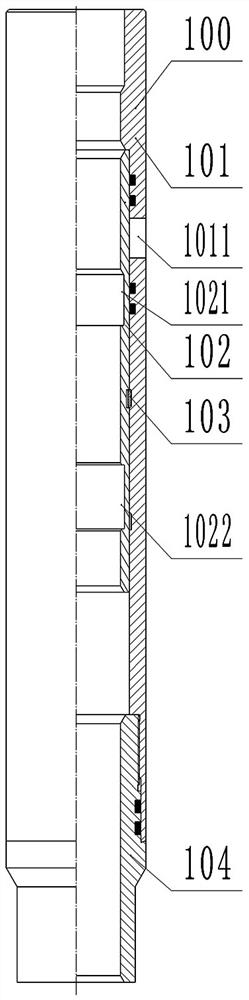

[0059] Here, there are multiple sliding sleeve switches arranged at intervals along the up and down direction, and the structures of each sliding sleeve switch are basically the same, such as figure 1 As shown, they are all composed of an outer sleeve 101, an inner sliding sleeve 102, a locking ring 103 and a lower joint 104. The outer sleeve 101 is connected to the main bo...

specific Embodiment 2

[0066] It differs from Embodiment 1 mainly in that: in Embodiment 1, the elastic locking structure arranged between the outer sleeve and the inner sleeve is a lock ring; in this embodiment, the elastic locking structure is a bow-shaped limit shrapnel, and The clips are snapped into the slots provided on the outer peripheral surface of the inner sliding sleeve, and the outer ends of the bow-shaped limiting shrapnels are set on the protrusions for matching with different slots on the inner wall of the jacket. Its structure can be referred to the bow-shaped limit shrapnel in the switch sliding sleeve in the Chinese invention patent whose authorized notification number is CN105672946B.

[0067] Of course, in other embodiments, the elastic locking structure can also adopt the anchor claw type limiting shrapnel in the switch sheath disclosed in the Chinese invention patent with the authorized notification number CN105696975B, which will not be repeated here.

Embodiment 1

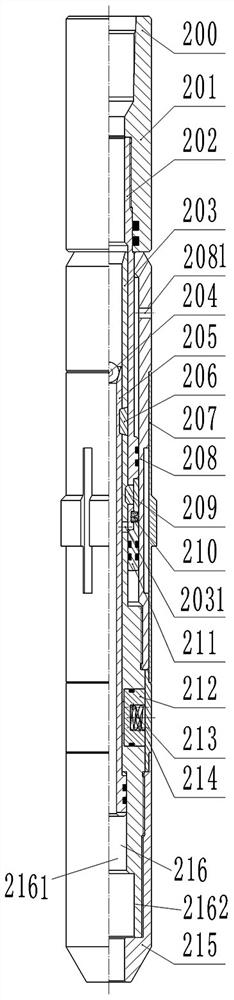

[0069] Such as Figures 2 to 7 As shown, the hydraulic opening tool 200 in this embodiment is used to run into the sliding sleeve switch 100 of the downhole string to drive the inner sliding sleeve 102 to move to the opening position to open the sliding sleeve switch.

[0070] The hydraulic closing tool 200 as a whole includes an upper joint 201 , a short connecting pipe 202 , an inner pipe 203 , an outer support pipe 208 , a ball seat 205 , a positioning ring 207 , a lifting bolt 212 , a pressure pipe 214 and a guide joint 215 .

[0071] Wherein, the external thread on the top of the connecting short pipe 202 is tightly connected with the internal thread of the upper joint 201 to form a main body of the joint, and the upper joint 201 is provided with a ring-shaped inner rim to stop and cooperate with the top end of the short connecting pipe 202 . Moreover, a sealing ring is provided between the upper joint 201 and the short connecting pipe 202 to seal the assembly gap between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com