Unit assembly type elephant trunk system

A prefabricated and slide pipe technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of the installation and dismantling process, the large amount of demolition work, and the inconvenience of branch erection, so as to improve the construction efficiency and The effect of safety, convenient operation and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

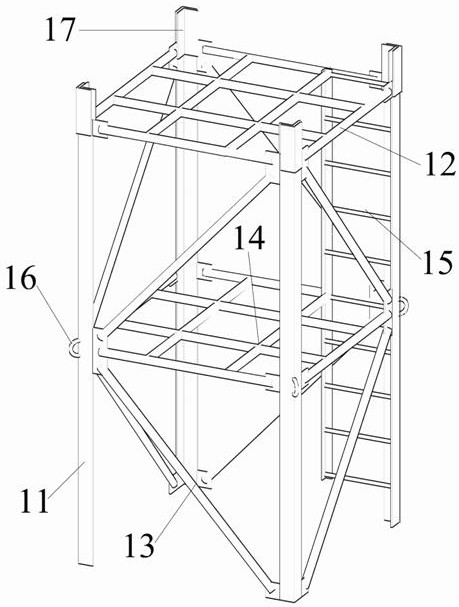

[0047] Embodiment 6, a unit-assembled slide pipe system, differs from Embodiment 5 in that a hook 16 is provided in the middle of the outer side of the vertical bar 11 , and a reinforcement 60 is connected to the hook 16 . The reinforcing part 60 is a cable wind rope, and one end of the cable wind rope is connected to the hook 16, and the other end is arranged on the ground, which can improve the stability of the device. A ladder 15 is connected to one side of the vertical support 10 . The climbing ladder is used for manual up and down, which is convenient for maintenance and disassembly, and can improve work efficiency.

Embodiment 7

[0048] Embodiment 7, a material delivery method of a unit-assembled chute system, including a single horizontal transportation mode and multiple horizontal transportation modes;

[0049] The unit-assembled chute system in the single horizontal transportation mode includes one horizontal transportation unit and two vertical transportation units. Hang the vertical support 10 to the stringer tube 30, fix the bottom vertical support 10 on the bottom of the foundation pit, then assemble the vertical support 10 sequentially from bottom to top, then hoist the horizontal slide pipe 20, and finally install each The reinforcement 60 of the support unit forms a chute system; the process of a single horizontal transport mode is as follows: the concrete material flows into the top diversion valve 402 from the horizontal chute 20 through the horizontal feed port 49, and the top diversion valve 402 is adjusted according to the position of the traction rope 46. control the position of the div...

Embodiment 9

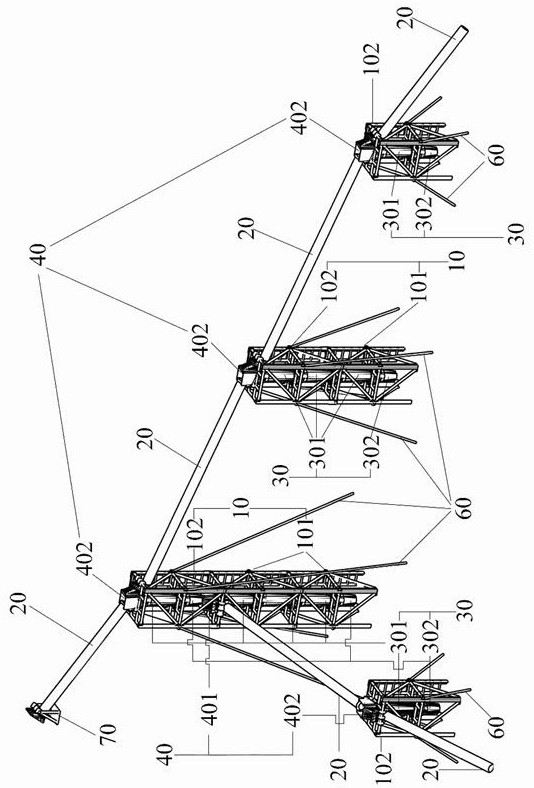

[0062] Example 9, such as figure 2 As shown, a unit-assembled chute system includes a main transverse transport unit and a branch transverse transport unit. The main transverse transport unit has three support units in total, the first support unit is composed of two lower support frames 101 and a top support frame 102, and the second support unit is composed of a lower support frame 101 and a top support frame 102. , the third support unit is a top support frame 102 . The branch transverse transport unit is a top support frame 102 . In other embodiments, the arrangement of branch transverse transport units, the number of support units and the number of lower support frames 10 in each support unit are set according to requirements.

[0063] Such as figure 2 As shown, the hanger 23 of the transverse chute 20 at the starting end of the main transverse transport unit is suspended on the top base 70 on the top of the foundation pit, and the pipeline 21 is inserted into the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com