Lightweight aluminum alloy battery cover

A technology of battery cover and aluminum alloy, which is applied in the direction of battery/battery traction, electric vehicles, superstructure, etc. It can solve the problems of power battery top cover and battery cover with limited space, heavy overall weight, environmental pollution, etc., and achieve design High flexibility and production efficiency, no mold cost, and simplified cover structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

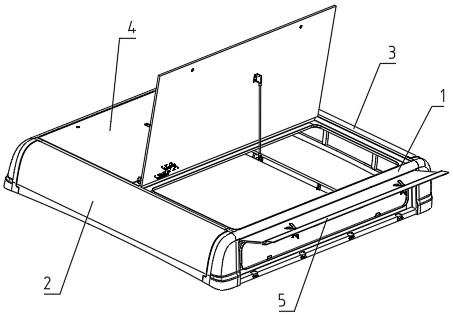

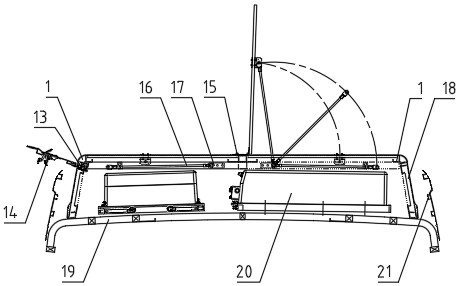

[0030] Such as Figure 1-2 As shown, a lightweight aluminum alloy battery cover, the main body is an aluminum profile, including a cover body frame 1, a front end face 2, a rear end face 3, a top inspection door 4 and a side inspection door 5; the front end face 2 and rear end face 3 They are respectively fixed on the cover frame 1 by bonding or welding, the top inspection door 4 is fixed on the upper end surface of the cover frame by hinges, and the side inspection door 5 is fixed on the left and right end surfaces of the cover frame by hinges.

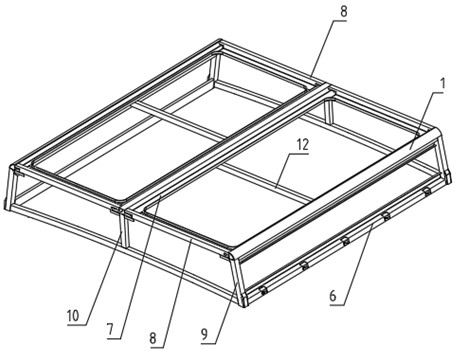

[0031] Such as figure 2 As shown, the cover frame is a cube structure, the horizontal frame is a crossbeam 8, the longitudinal frame is a side beam 6, and the vertical frame is a side column 9. The upper end of the cube structure is provided with a middle longitudinal beam 7, and the front and rear end faces are in the middle. A front column 10 is provided, and a middle crossbeam 12 is provided on the upper end surface, which is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com