Paper pulp container film covering method, equipment and production line

A pulp and container technology, applied in the field of pulp molding and laminating machinery, can solve the problems of affecting film temperature, unfavorable process simplification, waste of energy consumption, etc., to save equipment and man-hours, reduce film heating equipment, and reduce equipment and processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

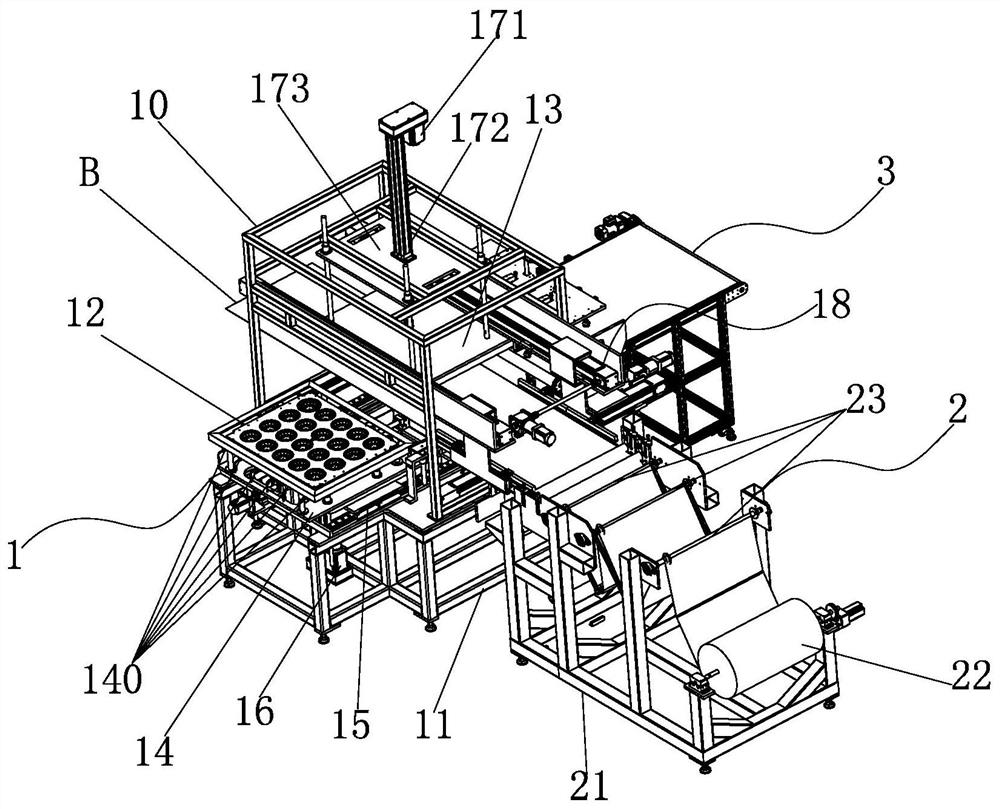

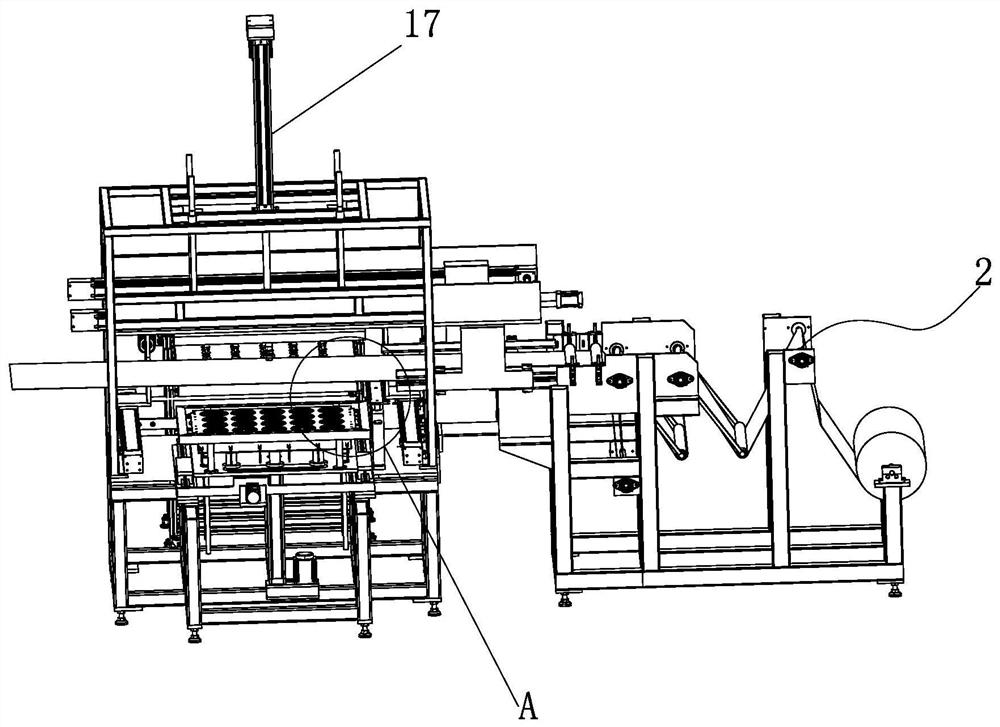

[0052] Such as figure 1 As shown, the pulp container coating equipment of this embodiment includes a frame 11, a lower die 12, an upper die 13, a lower die translation drive mechanism 15, a lower die lift drive mechanism 16, an upper die lift drive mechanism 17, a clamping traction Mechanism 18, cutting mechanism 19, unwinding mechanism 2 and reclaiming mechanism 3.

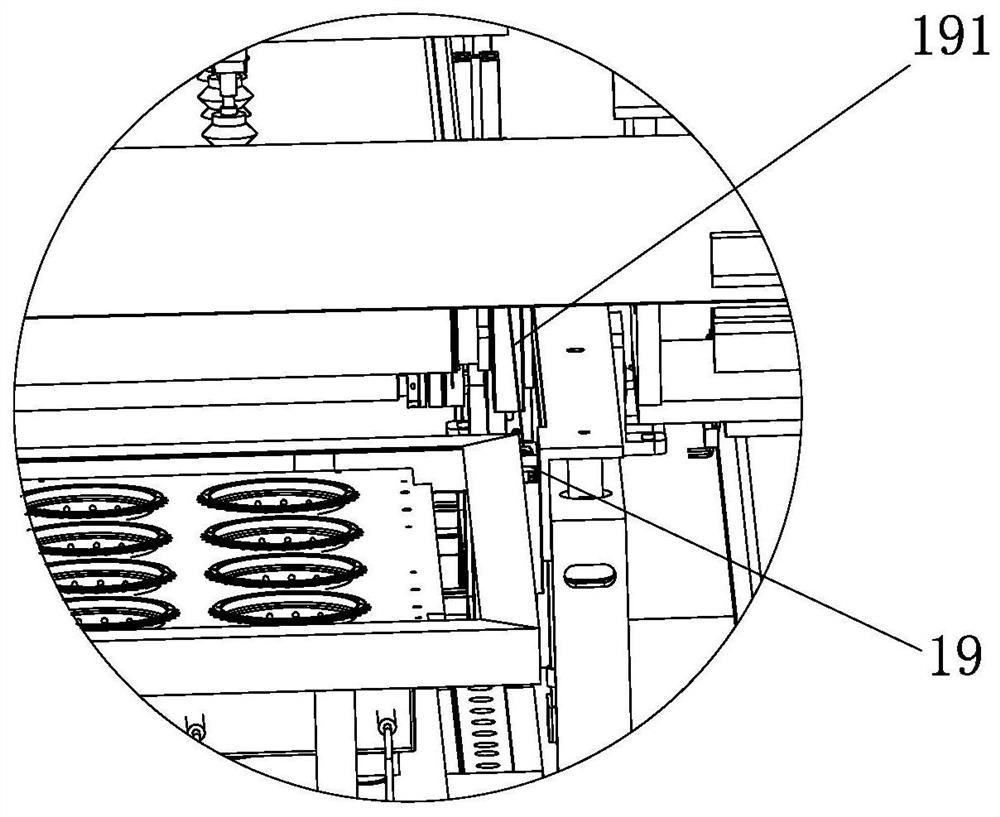

[0053] Such as figure 1As shown, the lower mold 12 in this embodiment is a lower mold for the round bowl coating. During specific implementation, the lower molds with corresponding shapes for various products can be replaced as needed, and are not limited to the ones in this embodiment. Round bowl form. The lower mold 12 of this embodiment specifically includes a lower membrane plate 121 for the round bowl coating, a demoulding frame 122 and a vacuum cover for coating. The vacuum cover for coating is located directly below the lower template 121, which is not shown in the figure. Such as Figure 5 As shown, t...

Embodiment 2

[0067] The other structures of this embodiment are the same as those of Embodiment 1, and the difference is that: the unwinding frame 21 is extended above, and the traction fixing frame 181 is set on the upper extension of the unwinding frame 21 . The traction fixture 181 still extends from above the unwinding mechanism to above the laminating station. Just the fixed position changes.

Embodiment 3

[0069] A method for covering a pulp container, said method comprising the steps of:

[0070] S1. Transmission: directly transfer the hot-pressed hot pulp container to the lower mold 12; The cold film B is tensioned and there is a gap with the opening of the hot pulp container; leaving a gap can transfer the heat of the pulp container to the cold film in advance, so that the cold film can be preheated, so that the film has better ductility .

[0071] S2, film covering, the upper mold 13 and the lower mold 12 are aligned and cooperate with each other so that the cold film B enters and fits on the inner wall and inner bottom of the hot pulp container, and the cold film B exchanges heat with the hot pulp container to heat up and melt The final cold film B is fixed on the inner wall and inner bottom surface of the hot pulp container, that is, a film-coated pulp container is obtained.

[0072] In the above pulp container coating method, in the above S1 step, the receiving lower mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com