Microfluidic preparation method of ZrO2/PS hybrid microspheres as well as product and application of same

A hybrid microsphere and microfluidic technology, applied in microsphere preparation, chemical instruments and methods, and methods for obtaining spatial resolution, etc., can solve the problems of poor processing performance, low imaging contrast, low refractive index, etc., and achieve excellent Processing performance, improved resolution, effects of controlled refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] a ZrO 2 The microfluidic preparation method of / PS hybrid microspheres, the specific preparation method comprises the following steps:

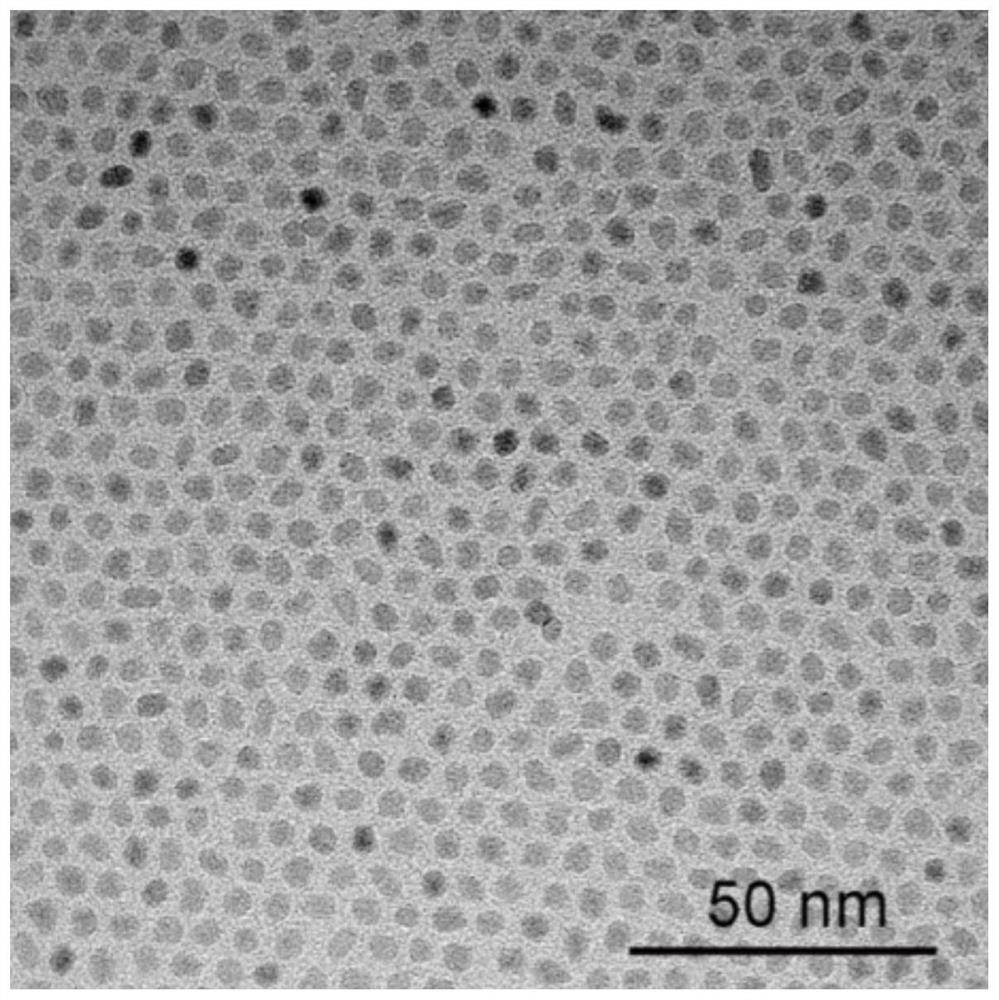

[0037] (1) Preparation of oil-soluble ZrO2 Nanoparticles: 5.6g of zirconium (IV)-isopropanol complex and 55ml of anhydrous benzyl alcohol were added to a 100ml polytetrafluoroethylene autoclave, and after it was sealed, the reactor was placed in React in an oven at 240°C for 4 days to get ZrO 2 Benzyl alcohol solution; the resulting ZrO 2 After centrifugation of the benzyl alcohol solution, the solid precipitate was ZrO 2 Nanoparticles were washed with absolute ethanol and centrifuged again, and the washing-centrifugation process was carried out 3 times to obtain purified ZrO 2 nanoparticles; the purified ZrO 2 The nanoparticles were dispersed in tetrahydrofuran (THF) solution dissolved with methacryloxypropyltrimethoxysilane (MPS) (wherein methacryloxypropyltrimethoxysilane (MPS) was mixed with ZrO 2 The mole of nanoparticles is ...

Embodiment 2

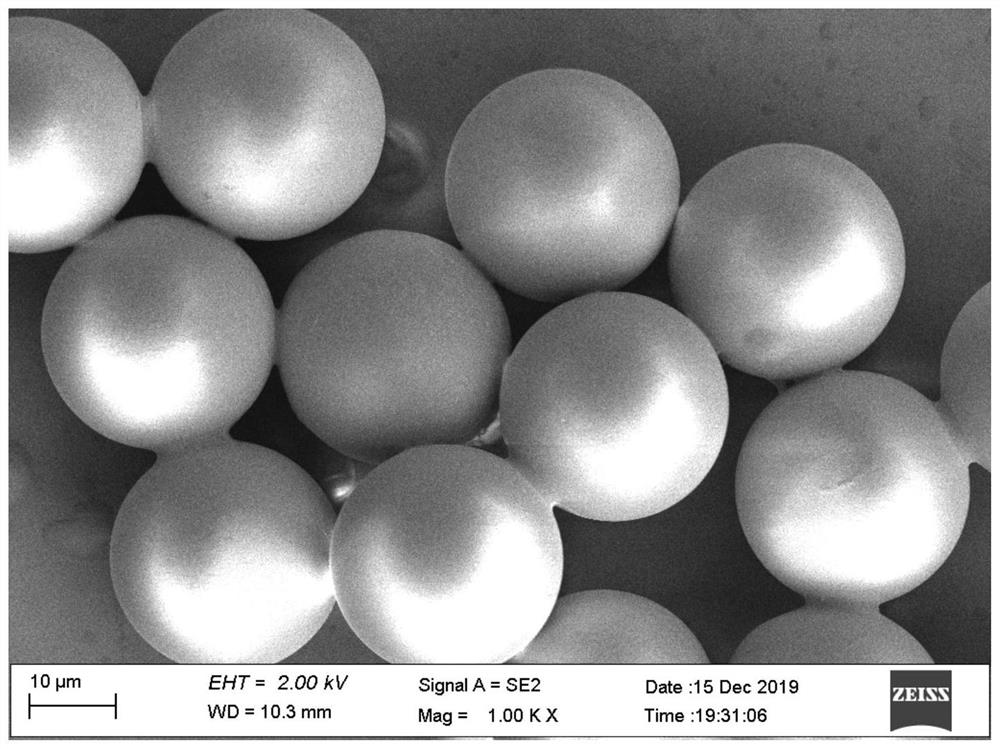

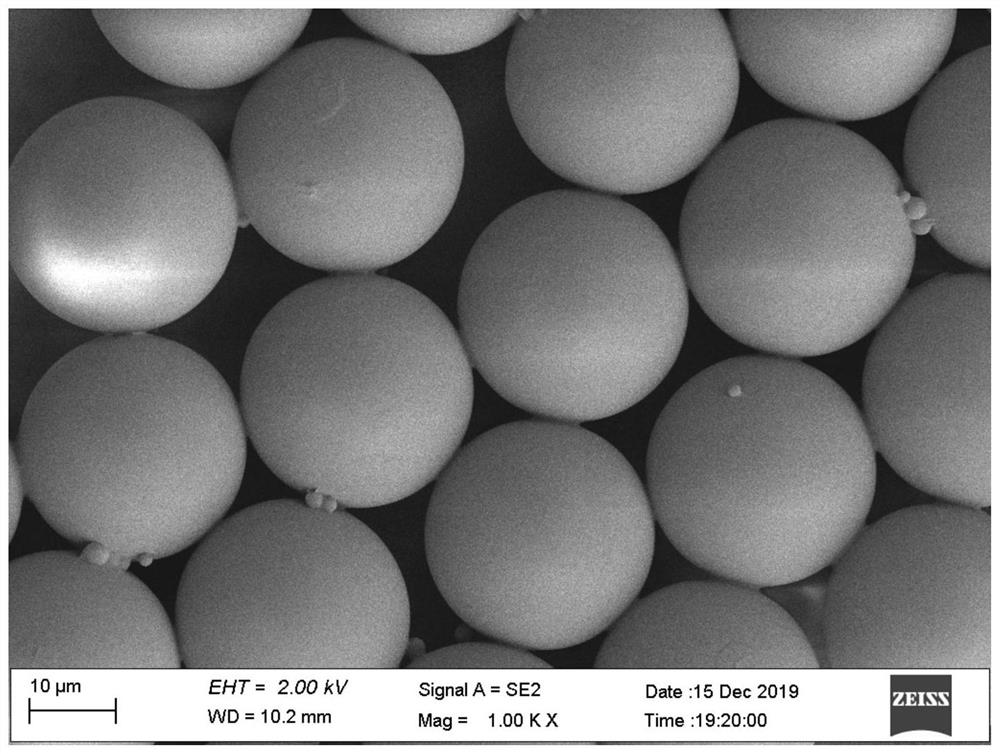

[0043] The flow rate of the dispersed phase solution in the focused microfluidic channel in Example 1 was changed to 5 μL / min and 8 μL / min respectively, and the other preparation methods were the same as in Example 1 to prepare ZrO with different particle sizes 2 / PS hybrid microspheres. When the flow rate of the dispersed phase solution is 5 μL / min, its SEM image is as follows image 3 As shown, the average particle size is 27 μm; when the flow rate of the dispersed phase solution is 8 μL / min, its SEM image is as follows Figure 4 As shown, the average particle size is 26 μm.

Embodiment 3

[0045] Change the flow rate of the dispersed phase solution in the focused microfluidic channel of Example 1 to 8 μL / min, and the flow rate of the polyvinyl alcohol (PVA) continuous phase solution to 30 μL / min, and the other preparation methods are the same as in Example 1. Prepare Obtain ZrO with an average particle size of 31 μm 2 / PS hybrid microspheres, the SEM image is as follows Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com