Medical efficient stirring device for zinc oxide processing

A stirring device and zinc oxide technology, applied in zinc oxide/zinc hydroxide, transportation and packaging, chemical instruments and methods, etc., can solve the problems of low efficiency, bloated equipment, poor stirring effect, etc., and achieve small size and convenient use , the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

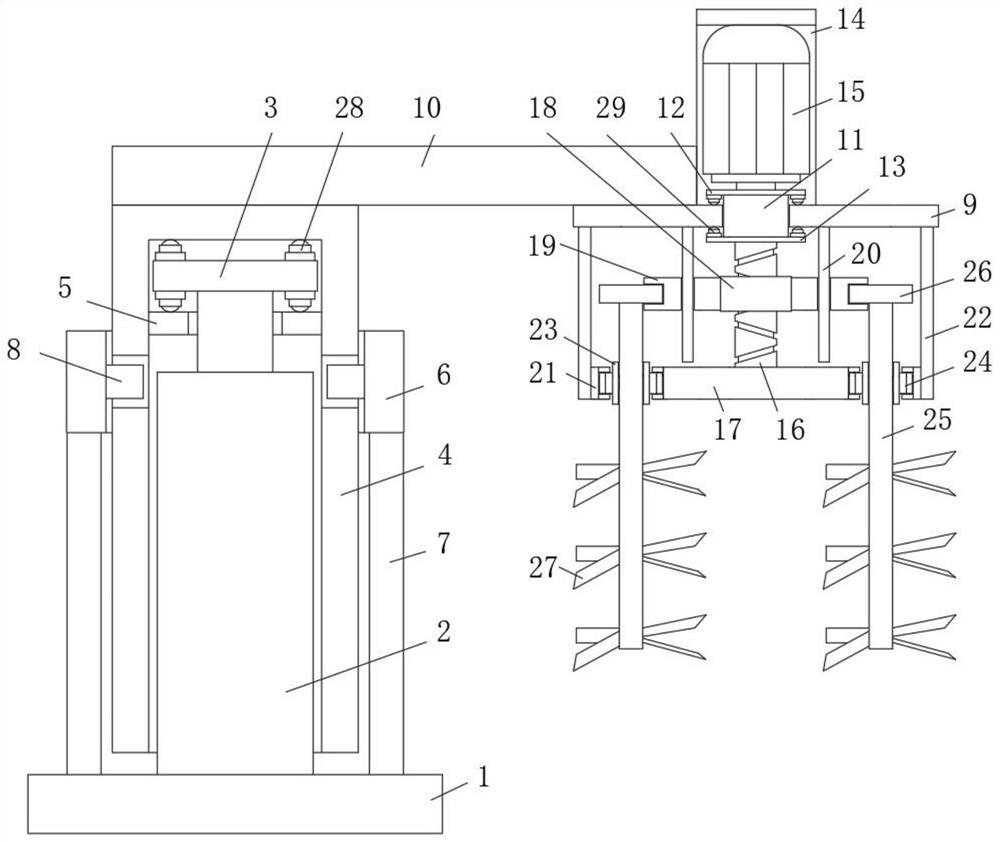

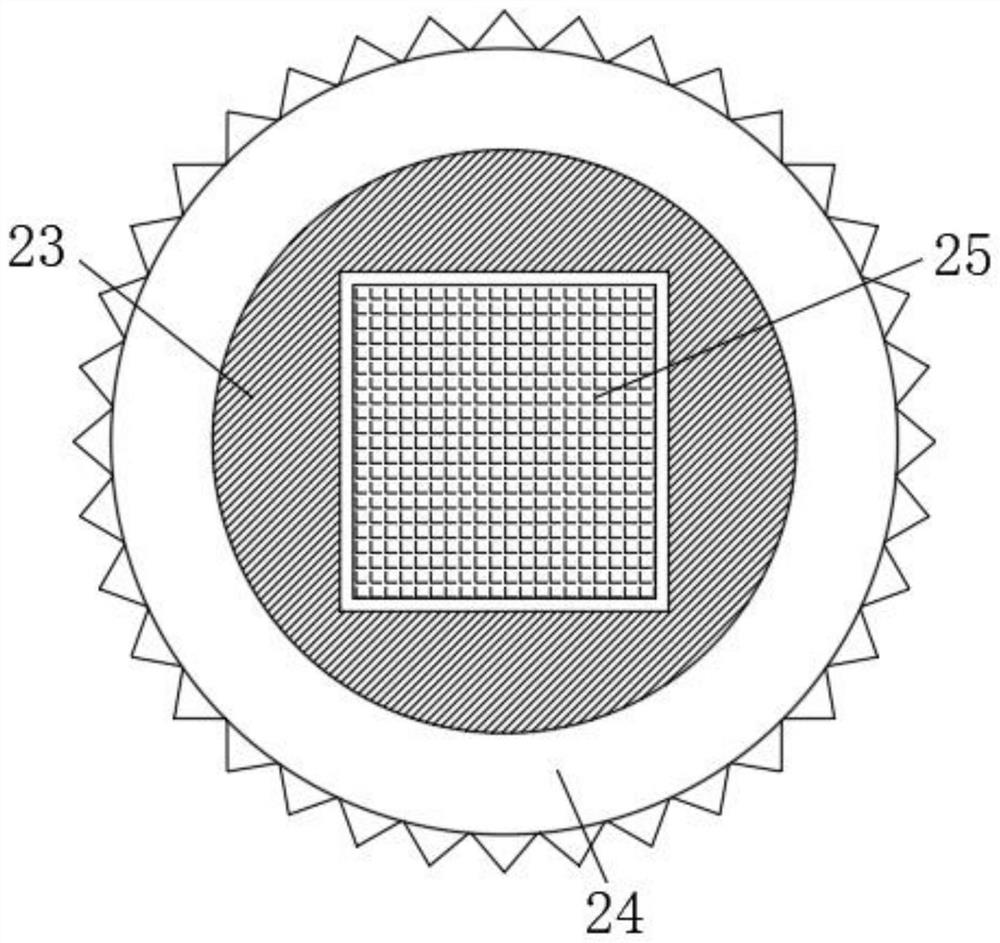

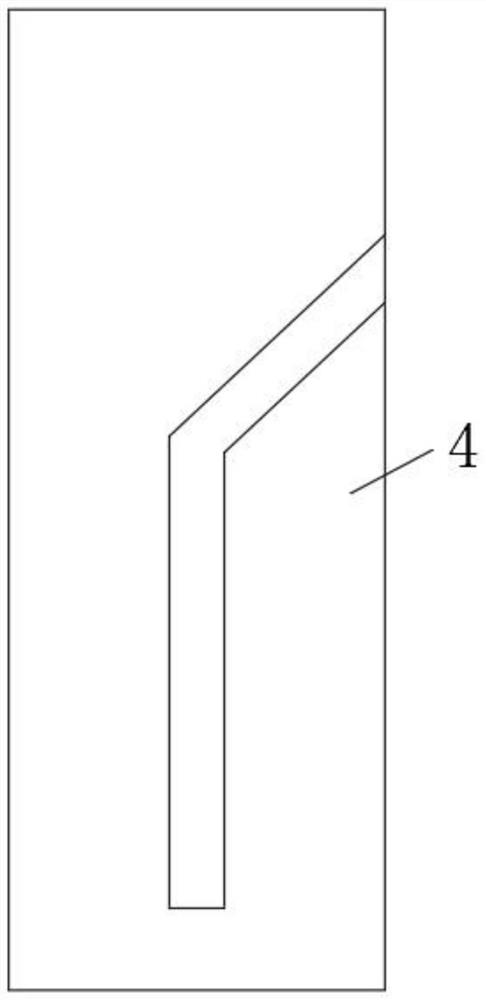

[0026] refer to Figure 1-4 , a high-efficiency stirring device for medical zinc oxide processing, including a lifting steering mechanism and a lifting stirring mechanism, the lifting steering mechanism includes a bottom plate 1, the top of the bottom plate 1 is fixed with a cylinder 2 by bolts, and the top of the output rod of the cylinder 2 is fixedly connected with a Circular plate 3, the outer rotation sleeve of circular plate 3 is provided with lifting drum 4, the inner wall of lifting drum 4 is fixedly connected with spacer ring 5, spacer ring 5 is located at the bottom of circular plate 3, and the vertical upper part of bottom plate 1 is provided with fixed Ring 6, the support column 7 is fixedly connected between the bottom of the fixed ring 6 and the bottom plate 1, and the outer side of the cylinder of the lifting drum 4 is provided with a track groove. The track groove is divided into two parts, the upper and lower parts, which communicate with each other. , the top...

Embodiment 2

[0030] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, there are multiple sets of stirring paddles 27 arranged vertically and equidistantly.

[0031] In this embodiment, the stirring effect is improved.

Embodiment 3

[0033] Such as Figure 1-4 As shown, the present embodiment is basically the same as Embodiment 1. Preferably, several anti-friction balls-28 are installed on the top side and the bottom side of the circular plate 3, and the anti-friction balls-28 are connected to the top side of the lifting drum 4 respectively. The inner wall and the top side of the spacer ring 5 are connected in rolling contact, and one side of the rotating shaft 11 and the upper plate 12 is equipped with several anti-friction balls 229,

[0034] In this embodiment, the arrangement of the anti-friction ball 1 28 and the anti-friction ball 2 29 greatly reduces the friction loss and improves the energy utilization rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com