A chemical raw material grinding device with mixing function

A chemical raw material and grinding device technology, which is applied in the direction of mixers, transportation and packaging, chemical instruments and methods, etc., can solve the problems of inability to reciprocate in a straight line of the mixing cylinder, low work efficiency, poor mixing effect, etc., and achieve efficient mixing The effect of mixed processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

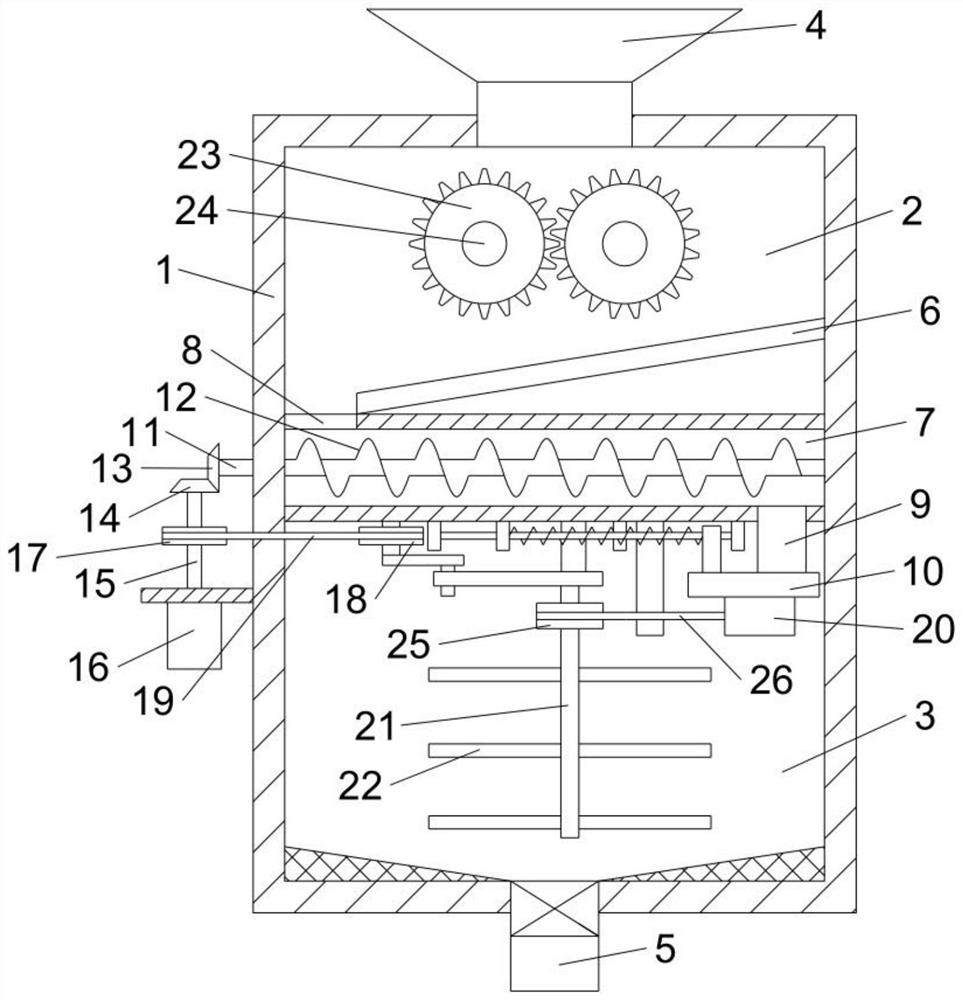

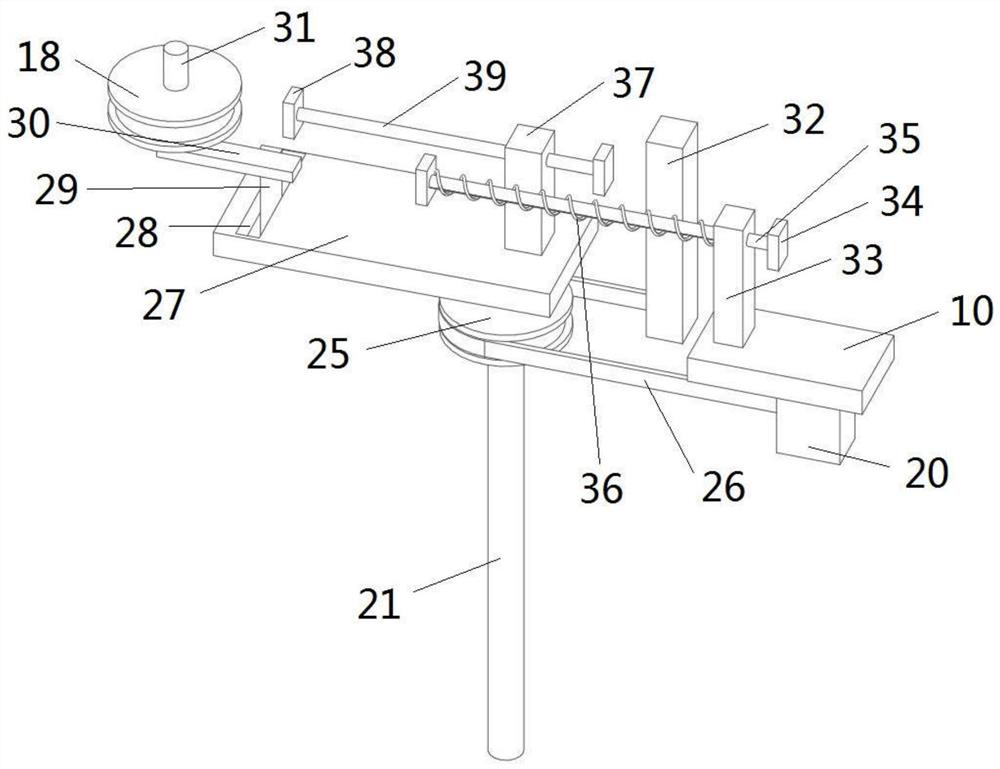

[0023] Refer to attached Figure 1-2 , this embodiment provides a chemical raw material grinding device with a mixing function, including a grinding chamber 2, a mixing chamber 3 and a material delivery chamber 7, and the grinding chamber 2, the mixing chamber 3 and the material delivery chamber 7 are all It is arranged in the casing 1; the top and the bottom of the casing 1 are respectively provided with a hopper 4 and a discharge port 5, the hopper 4 communicates with the grinding chamber 2, and the discharge port 5 communicates with the mixing chamber Material chamber 3 communicates.

[0024] In addition, the grinding chamber 2 is provided with a grinding assembly for grinding materials, and the grinding assembly includes two sets of grinding rollers 23 meshing with each other for grinding chemical raw materials; There is a feeding chamber inlet 8 and a feeding chamber outlet 9, the grinding chamber 2 communicates with the feeding chamber 7 through the feeding chamber inle...

Embodiment 2

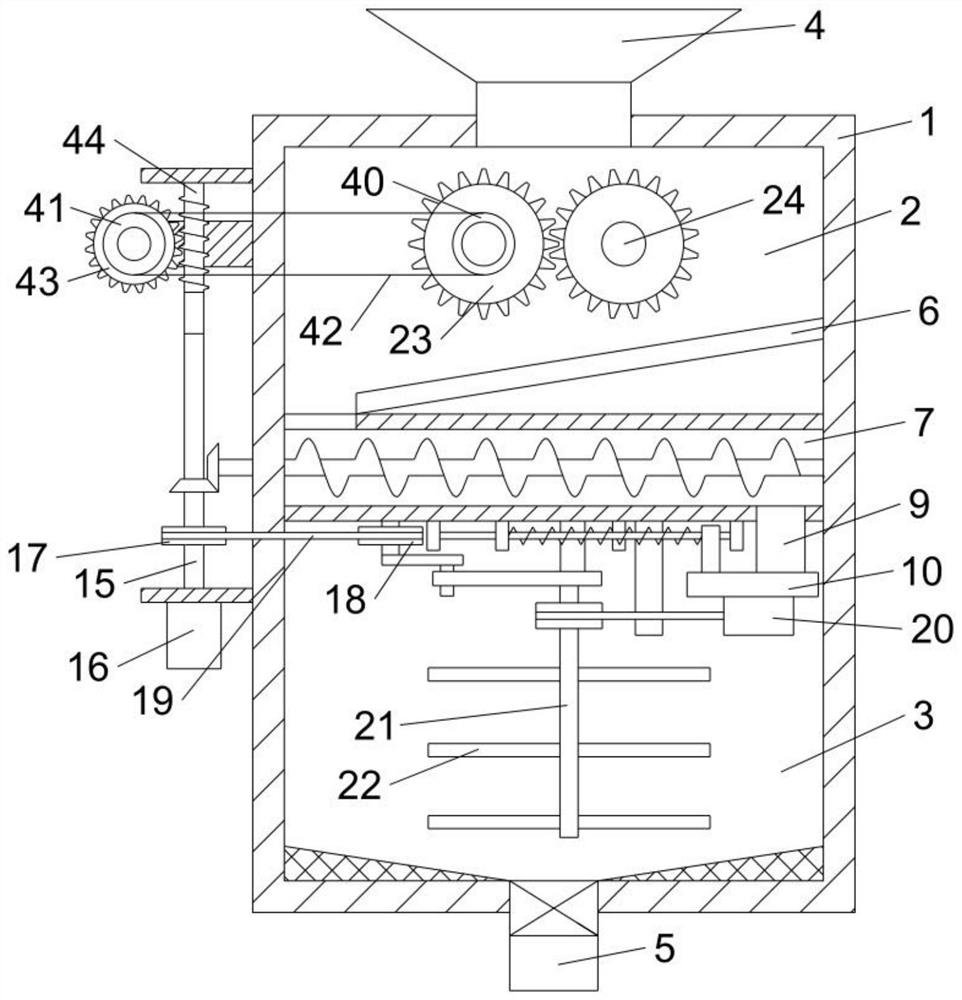

[0034] Refer to attached image 3 , in order to facilitate the grinding operation, this embodiment is improved on the basis of embodiment 1. Specifically, the first transmission shaft 15 is also fixedly connected with the worm 44, and the worm 44 is rotatably installed in the box body 1 The outer side; the worm 44 meshes with the worm wheel 43, and the worm wheel 43 is also fixed with a second drive wheel 41 for driving the grinding assembly for grinding operation.

[0035] Specifically, the grinding assembly includes two groups of grinding roller shafts 24 rotatably installed in the grinding chamber 2 and two groups of meshing grinding rollers 23, and the two groups of grinding rollers 23 are respectively fixedly installed with two groups of grinding roller shafts 24 and a second driven wheel 40 is fixed on one of the grinding roller rotating shafts 24, and the second driven wheel 40 is in drive connection with the second driving wheel 41 through the second transmission membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com