Integrated circulating cold water heat exchange system of dehumidification mechanism and drying machine dehumidification mechanism

A technology of heat exchange system and circulating cold water, which is used in cooling fluid circulation devices, drying solid materials, drying, etc., can solve the problems of affecting the overall appearance of the equipment, large on-site installation workload, inconvenient transfer and transportation, etc. Small area, quick on-site installation, saving equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

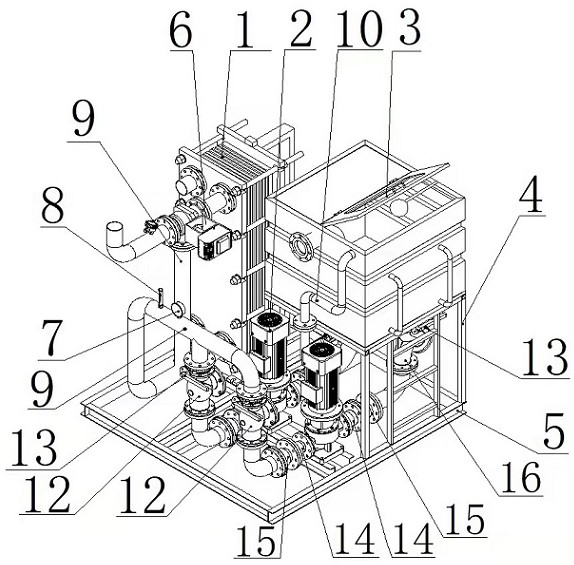

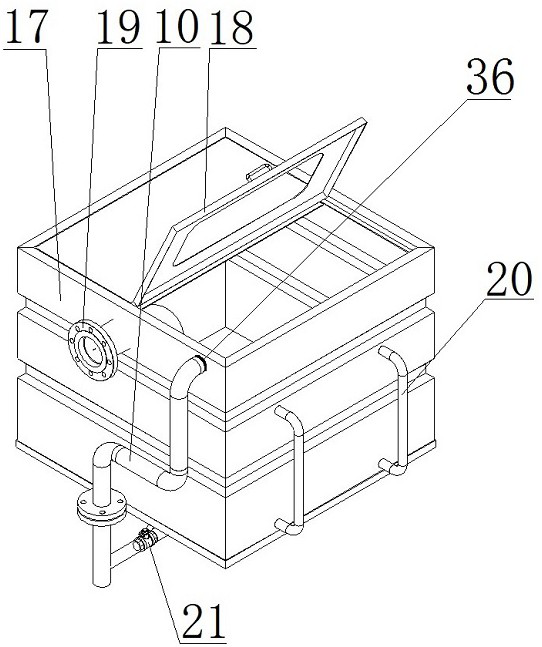

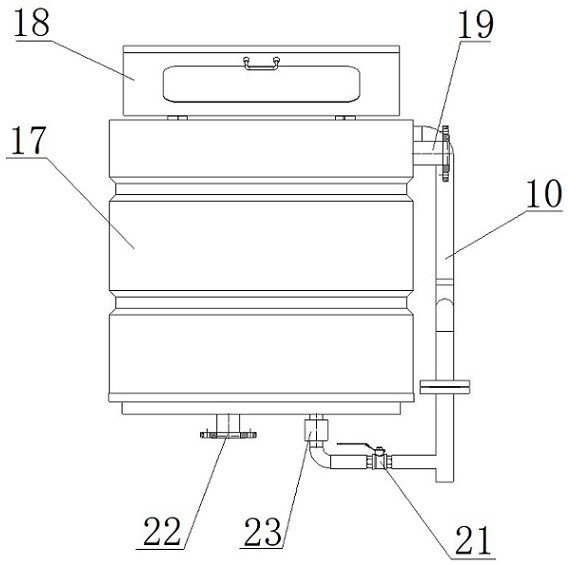

[0024] An integrated circulating cold water heat exchange system 33 of a dehumidification mechanism (abbreviation: integrated circulating water heat exchange system), the main point of the innovative overall implementation plan is to improve the existing distributed circulating cold water heat exchange system into one Chemical circulating cold water heat exchange system 33, including plate radiator 1, circulating water pump 2, circulating water tank 3, water tank support 4, integrated chassis 5, pressure gauge 7, thermometer 8, dual-purpose pipeline 9 (double suction confluence and tank Water return dual-purpose pipeline), overflow and discharge confluence pipeline 10, Y-shaped filter 16; the complete circulating water heat exchange system 33 actually also includes a surface cooler 32 and a cooling tower 34. For the sake of description, the present invention only highlights Integrated part; all the components between the surface cooler 32 and the cooling tower 34 are centrally ...

Embodiment 2

[0036] A dehumidification mechanism of a dryer, that is, a filter cake dehumidification mechanism of a closed filter cake dryer, using the integrated circulating cold water heat exchange system 33 of the dehumidification mechanism provided by the present invention (abbreviation: integrated circulating water heat exchange system); the The dehumidification mechanism of the dryer, that is, the dehumidification and drying mechanism of 7-30 ℃ low-temperature condensed steam, mainly consists of a refrigeration compressor 61, a cold water evaporator (gasification heat-absorbing refrigeration), a condenser (refrigeration unit), and a circulating cold water heat exchange system 33 It consists of a surface cooler 32 and a cooling tower 34; it can condense the steam evaporated from the wet cake strips in the high-temperature drying zone into water, and further dry the initially dried cake strips into dry cake strips with a moisture content of about 10%. The technical part shared by the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat transfer area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com