Crop airing device

A drying device and a technology for crops, applied in the direction of grain drying, drying of solid materials, dryers for static materials, etc., can solve the problems of high labor intensity, heavy workload, and low drying efficiency, so as to improve drying efficiency and save working time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

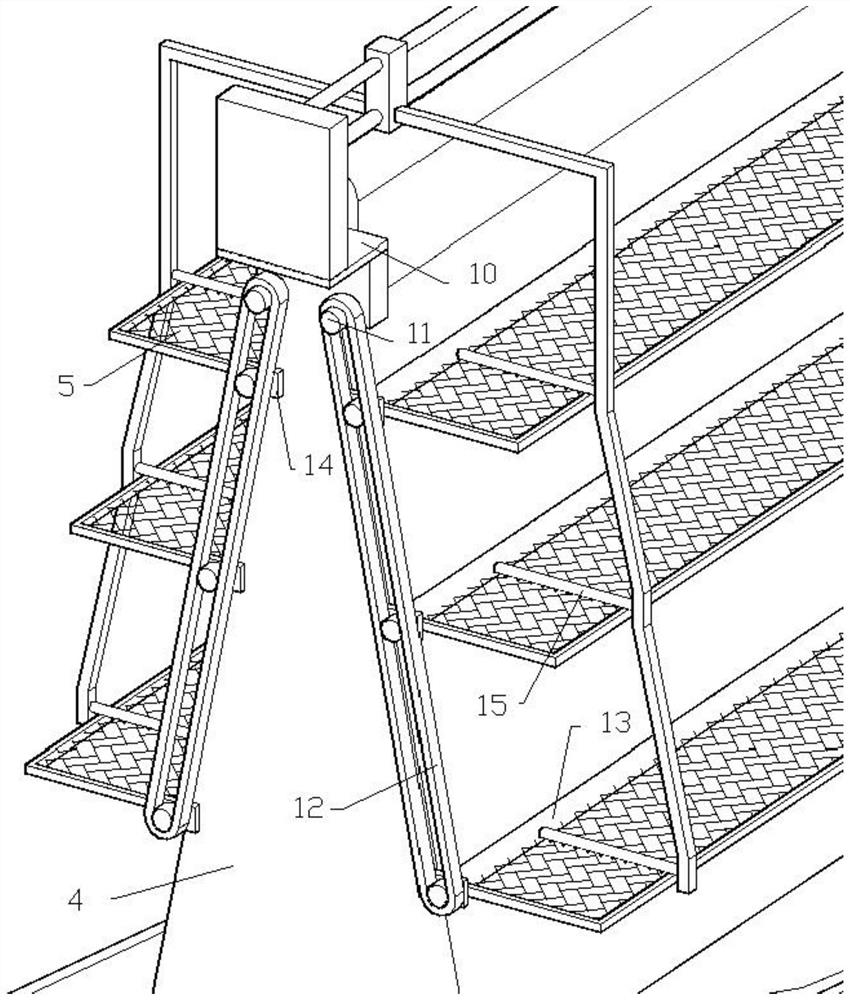

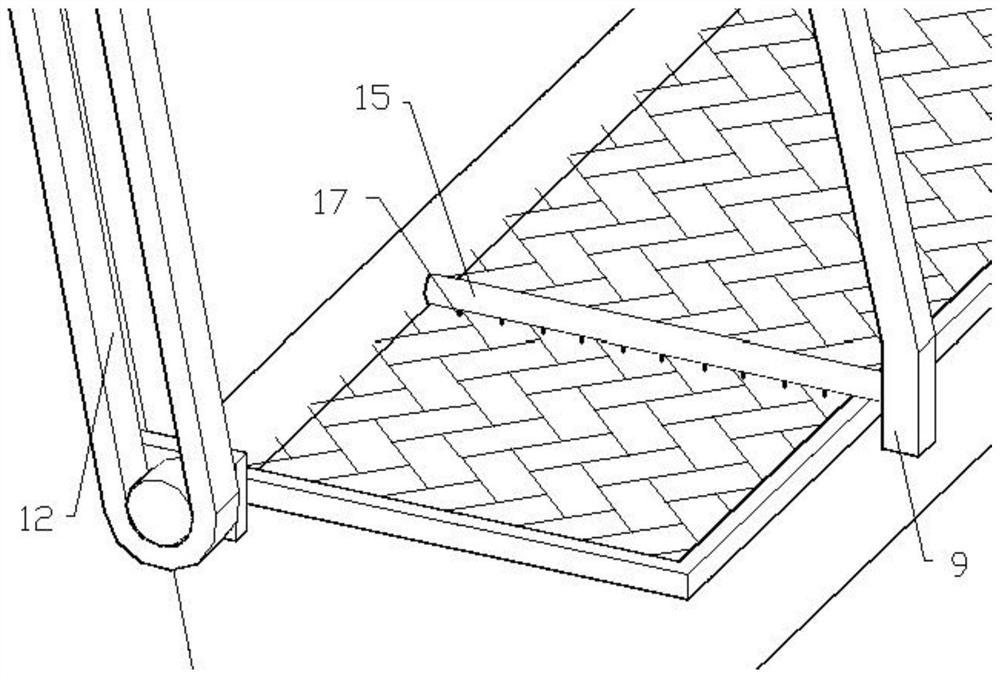

[0017] Such as Figure 1 to Figure 3 As shown, a crop drying device includes a number of drying units arranged equidistantly, wherein each drying unit includes a base 1, and the front and rear sides of the upper surface of the base 1 are connected by support rods to the same side. The trough 2, the electric control rotating seat 3 is arranged at the middle position on the upper surface of the base 1, and the mounting seat 4 whose cross-section is isosceles trapezoidal shape and the upper end is arc-shaped is connected to the top of the electric control rotating seat 3, and the two sides of the mounting seat 4 are There are several rotating shafts 13 equidistantly spaced from top to bottom on the inclined surface, both sides of the rotating shafts 13 pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com