Automatic forming device for stainless steel corrugated pipe joint for gas appliance

A gas appliance and automatic forming technology, which is applied in the field of automatic forming devices for stainless steel bellows joints for gas appliances, can solve problems such as cumbersome operations, and achieve the effects of improving production efficiency and facilitating flattening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following description is used to disclose the invention to enable those skilled in the art. Preferred embodiments in the following description are only example, and those skilled in the art can think of other obvious variations.

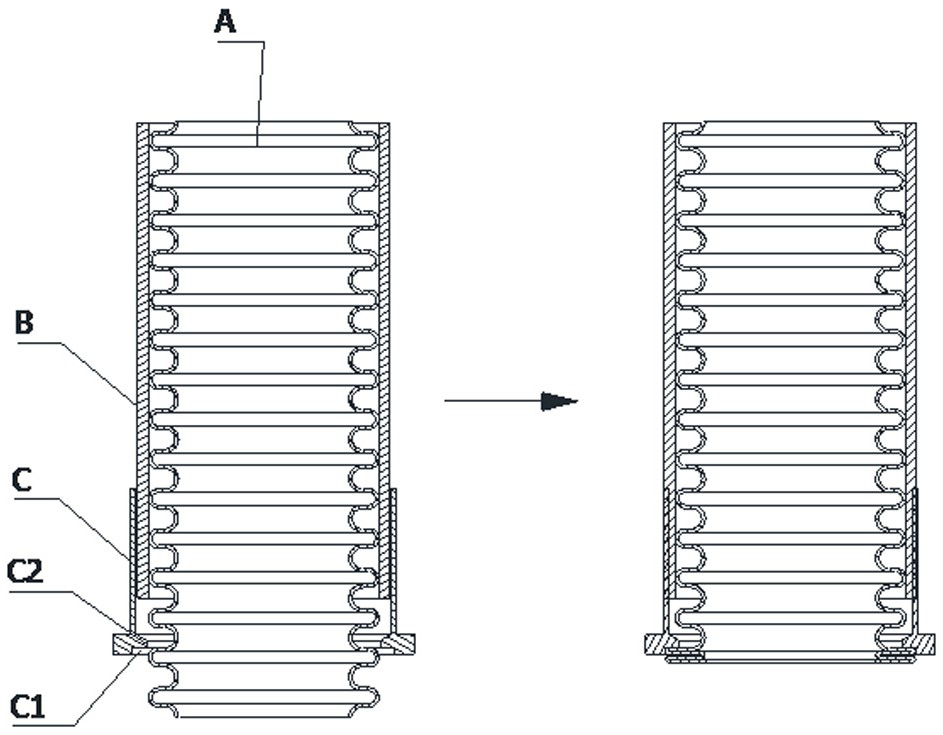

[0053] In order to solve the technical problem of gas stainless steel bellows joint formed by the need of artificial assembly, such as Figure 1-15 Shown provide the following technical solutions:

[0054] A gas appliance with a stainless steel bellows joint automatic molding apparatus comprising,

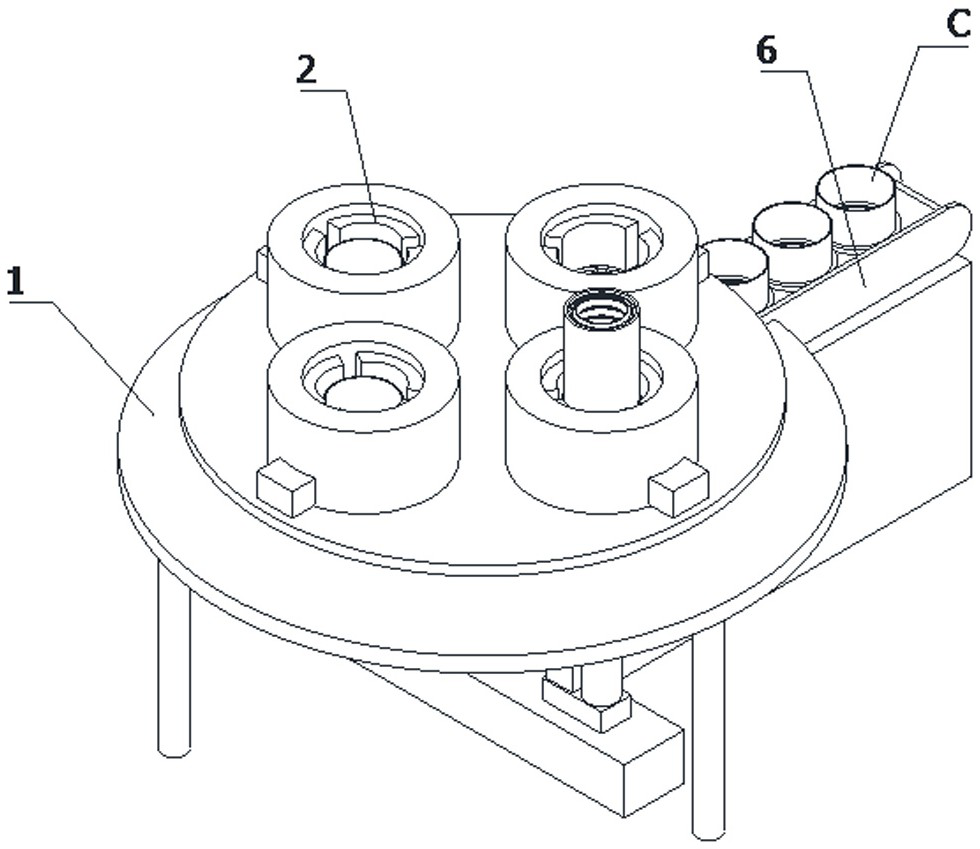

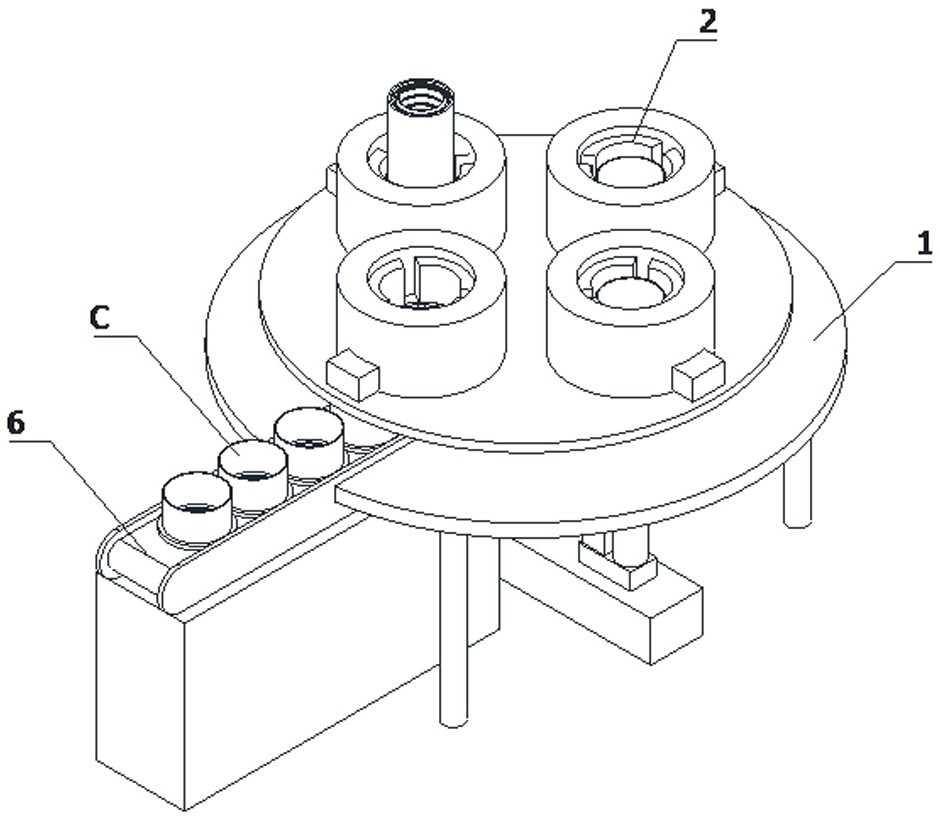

[0055] A rotary table, comprising successively a first circumferential direction thereof uniform distribution station, a second station and the third station;

[0056] Radial necking assembly 2, a vertical direction is disposed coaxially to the end of the first station, the second station and the third station, said radial necking assembly 2 for radial extrusion method necking Orchid;

[0057] A first station and a second station on top of the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com