Adjustable calibration type electroslag pressure welding tool

An electroslag pressure welding and adjustable technology, which is applied in the field of measuring equipment and electroslag pressure welding, can solve the problems of large inclination angle, simple structure of measuring instruments, and inability to meet the needs of workers for measuring and using, so as to reduce deviation and ensure The effect on overall security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

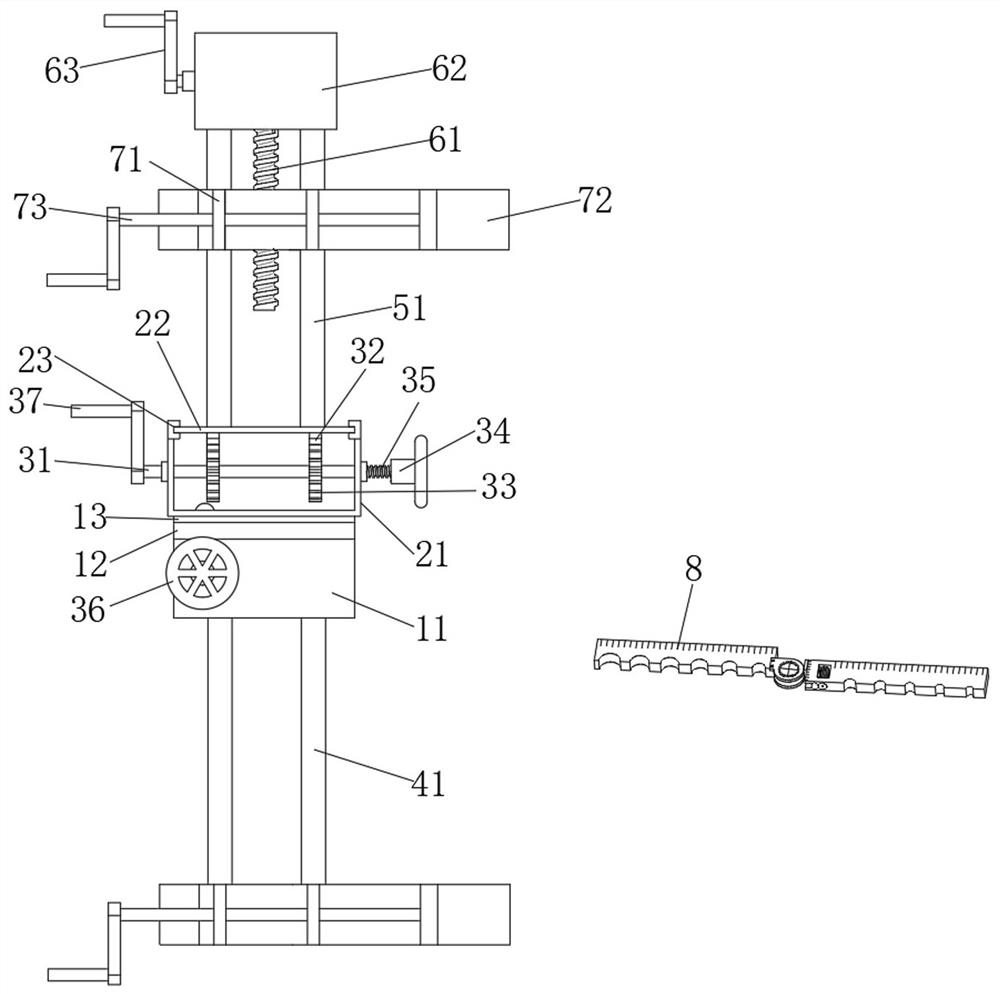

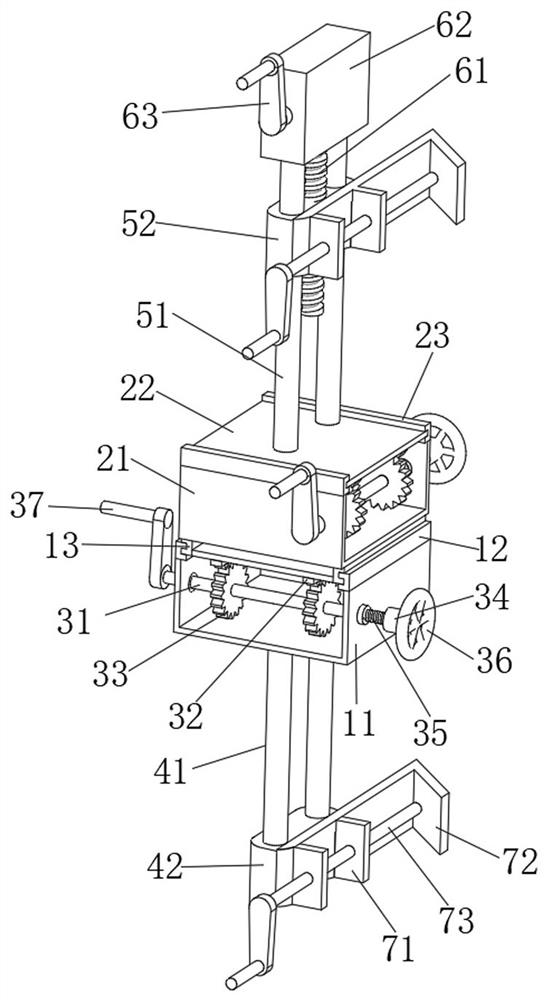

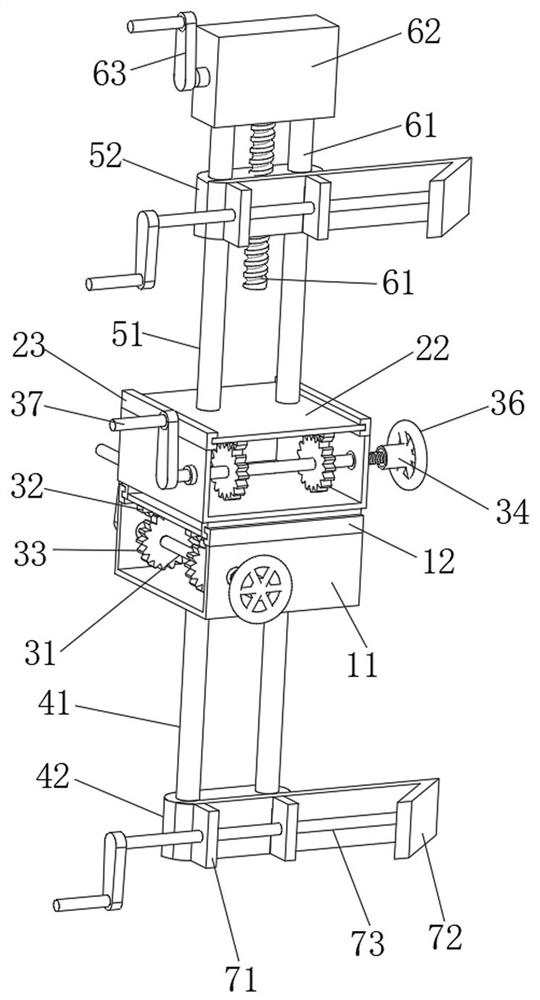

[0038] according to Figure 1-5 As shown, it includes a docking fixture and a measuring instrument 8 arranged on one side of the docking fixture. The docking fixture includes an offset mechanism, an upper clamping mechanism, and a lower clamping mechanism;

[0039] Such as figure 1 , figure 2and image 3 As shown, the offset mechanism includes an X-axis support 11, a lower seat 13, a lower adjustment assembly, a Y-axis support 21, an upper slide plate 22, and an upper adjustment assembly; the X-axis support 11 is connected to the top of the lower clamping mechanism, and X Both side wall tops of the shaft support 11 are equipped with sliding rails 12. The sliding seat 13 includes two U-shaped plates and a horizontal plate. The two U-shaped plates are respectively slidably connected with the two sliding rails 12. Between the U-shaped plates, the lower adjustment assembly is installed on the X-axis support 11 and can make the slide seat 13 slide axially along the slide rail 1...

Embodiment 2

[0050] On the basis of Embodiment 1, the similarities between this embodiment and Embodiment 1 will not be repeated, and the differences are as follows: Another method of using the measuring instrument 8, when the upper and lower steel bars are connected and welded to produce a certain offset , by clamping the lower steel bar through the measuring hole 89 on the lower specification ruler 82, when the axes of the upper and lower steel bars are not on the same axis, move the lower specification ruler 82 close to the upper steel bar for measurement, and in the process, the worm screw 88 can be slowly rotated, and the worm screw 88 Engage the transmission worm gear 812, and then under the joint action of the slider 811, the connecting block 810 and the limit hole 87, the connecting shaft 86, the connecting ring 83 and the upper specification ruler 81 are moved to the upper side of the steel bar, and the upper specification ruler 81 When the measuring hole 89 is close to the upper s...

Embodiment 3

[0052] On the basis of Embodiment 1, the similarities between this embodiment and Embodiment 1 will not be repeated, and the differences are as follows: Another method of using the measuring instrument 8, when the axes of the upper and lower steel bars are not on the same axis, by welding The package is placed at the connecting ring 83, and the upper specification ruler 81 and the lower specification ruler 82 are slightly rotated so that the upper specification ruler 81 and the lower specification ruler 82 are close to the upper and lower steel bars, and the upper specification ruler 81 and the lower specification ruler 82 are close to the steel bars. During the process, the movement of the connecting shaft 86 and the connecting ring 83 produces a certain angle offset, and then through the cooperation of the cross pointer 91 and the dial 92, the bending angle of the upper and lower steel bars can be obtained by measuring the position of the pointer rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com