Non-defective plastic mold material monitoring and feedback system

A technology of feedback system and plastic mold, which is applied in the parts of TV system, analysis materials, measuring devices, etc., can solve the problems of increasing the waste of manpower and material resources, not being able to monitor and feedback good-quality plastic film materials, and not being able to check products sequentially. , to achieve the effect of increasing the speed of taking pictures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

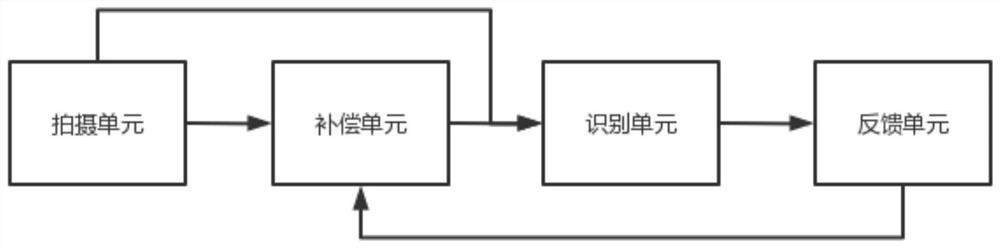

[0045] see figure 1 As shown in the figure, the good product monitoring and feedback system for plastic molding is based on the scene where the industrial camera is used for the good product monitoring of the collector, especially in the use scene of high speed, high resolution and high recognition rate.

[0046] During specific implementation, it includes a shooting unit, a compensation unit, a recognition unit and a feedback unit;

[0047] Wherein, the photographing unit is used to obtain the image information of the plastic mold;

[0048] In some embodiments, the photographing unit includes a main photographing unit, a secondary photographing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com