In-situ and indoor dual-purpose large clipper

A dual-purpose, in-situ technology, applied in the field of civil engineering surveys, can solve problems such as unsatisfactory mechanical strength, inability to perform in-situ experiments, and cumbersome installation of large-scale instruments, and achieve the goal of ensuring strength, facilitating transportation, and reducing structural size and weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The accompanying drawings are for illustrative purposes only, and should not be construed as limiting the present invention; in order to better illustrate this embodiment, certain components in the accompanying drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product; for those skilled in the art It is understandable that some well-known structures and descriptions thereof may be omitted in the drawings. The positional relationship described in the drawings is for illustrative purposes only, and should not be construed as limiting the present invention.

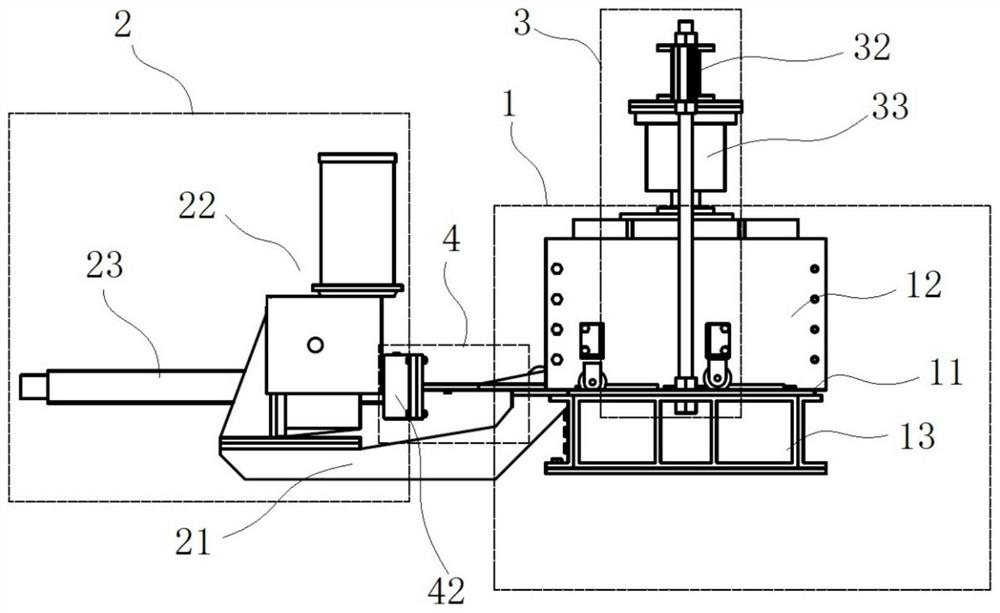

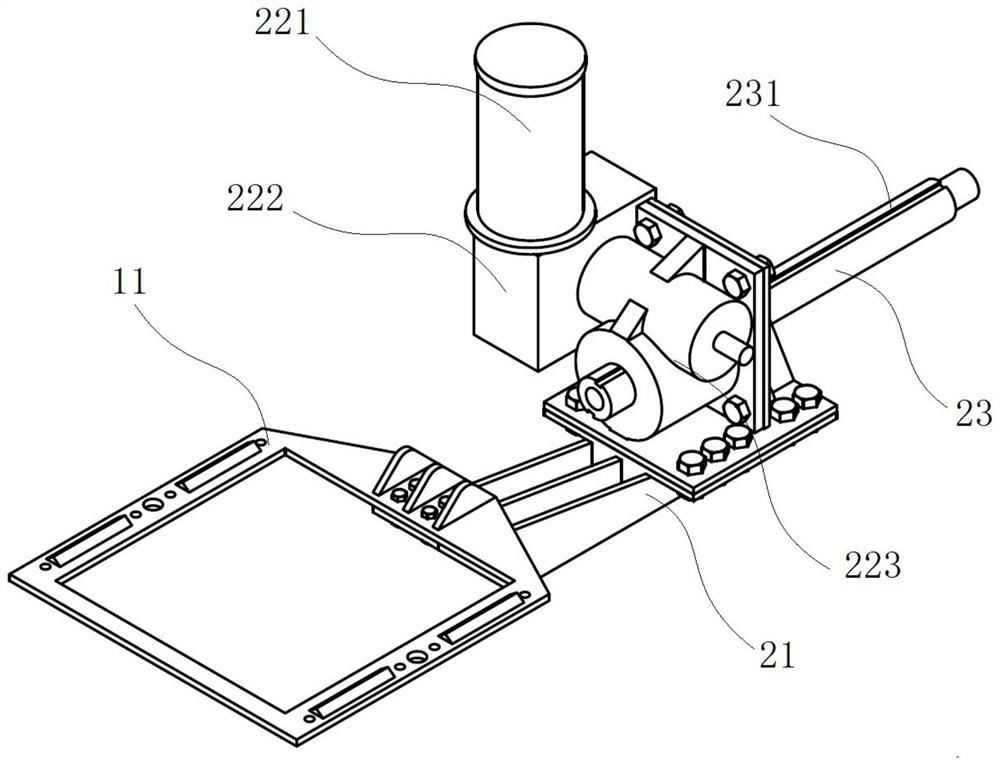

[0029] Such as figure 1 with figure 2 As shown, an in-situ-indoor dual-purpose large-scale clipper includes a mounting plate 11, an upper box 12 and a lower box 13 for containing soil samples, a horizontal clipper system 2, a normal pressurization system 3 and a pressure transmission system. Sensing mechanism 4; upper box 12 has no bottom cover, lower box 13 has no top cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com