Engine rotor blade dynamic signal output method and equipment based on digital board card

A technology of dynamic signals and rotor blades, which is applied in engine testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as limited simulation parameters and complex structures, and achieve high flexibility and low research costs. And test cost, shorten the effect of R & D cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

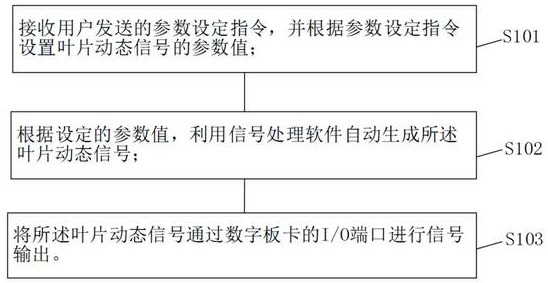

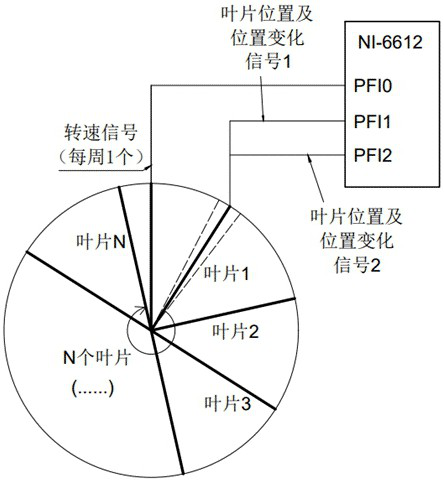

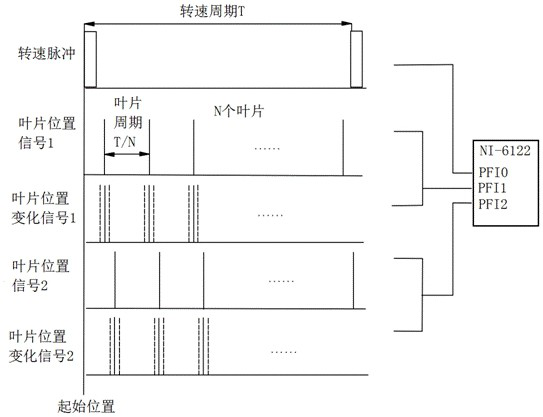

[0043]In order to solve the technical problems of complex structure of the blade dynamic signal simulation system and limited simulation parameters in the prior art, the embodiment of the present application provides a method for outputting the dynamic signal of the engine rotor blade based on a digital board, which can be used in the laboratory In the environment, use signal processing software to generate signal waveforms, and then use digital boards, preferably NI-6612 digital boards, to simulate the dynamic signal of the engine rotor, and develop the engine without building a physical tester The development and debugging of the rotor dynamic signal acquisition and analysis system greatly reduces research and test costs and shortens the development cycle.

[0044] For the convenience of description, unless otherwise specified, the execution subject of the embodiment of the present application is mainly a personal computer, including but not limited to a desktop computer, a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com