Method for coating fire coal fly ash with nanoparticles

A technology of nano-particles and over-combustion of coal, which is applied in the direction of combustion method, fuel burned in melting state, combustion type, etc., can solve the problem of ash on the heating area of the boiler, achieve the effect of prolonging the life of the boiler, improving the power generation efficiency of the boiler, and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

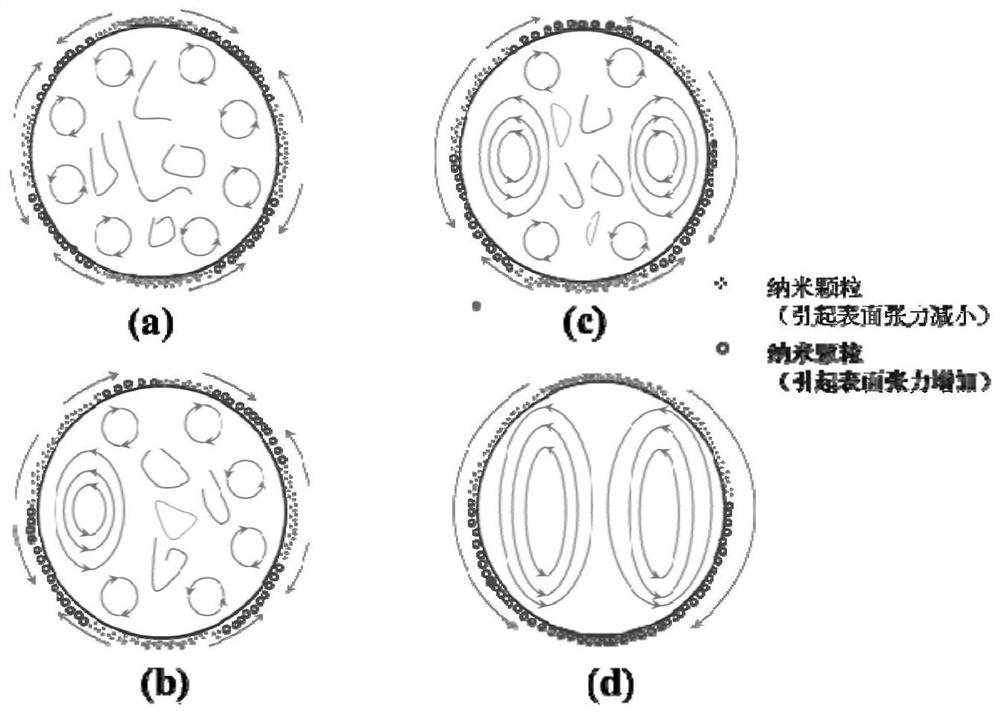

[0034] A method of coating coal-fired fly ash with nanoparticles in this embodiment, simultaneously injecting two different streams of nanoparticles into the impinging flow reactor 10 in a tangential swirl, and the different streams of nanoparticles interact with the fly ash of coal-burning respectively , trigger Marangoni convection, and realize the modified coating of coal-fired fly ash. Specifically, in this embodiment, the first nanoparticle flow causes the surface tension of coal-fired fly ash to increase, and Al 2 o 3 At least one of , MgO, MnO, CaO, the second nanoparticle flow causes the surface tension of coal-fired fly ash to increase, and SiO can be used 2 、TiO 2 , B 2 o 3 、Na 2 At least one of O.

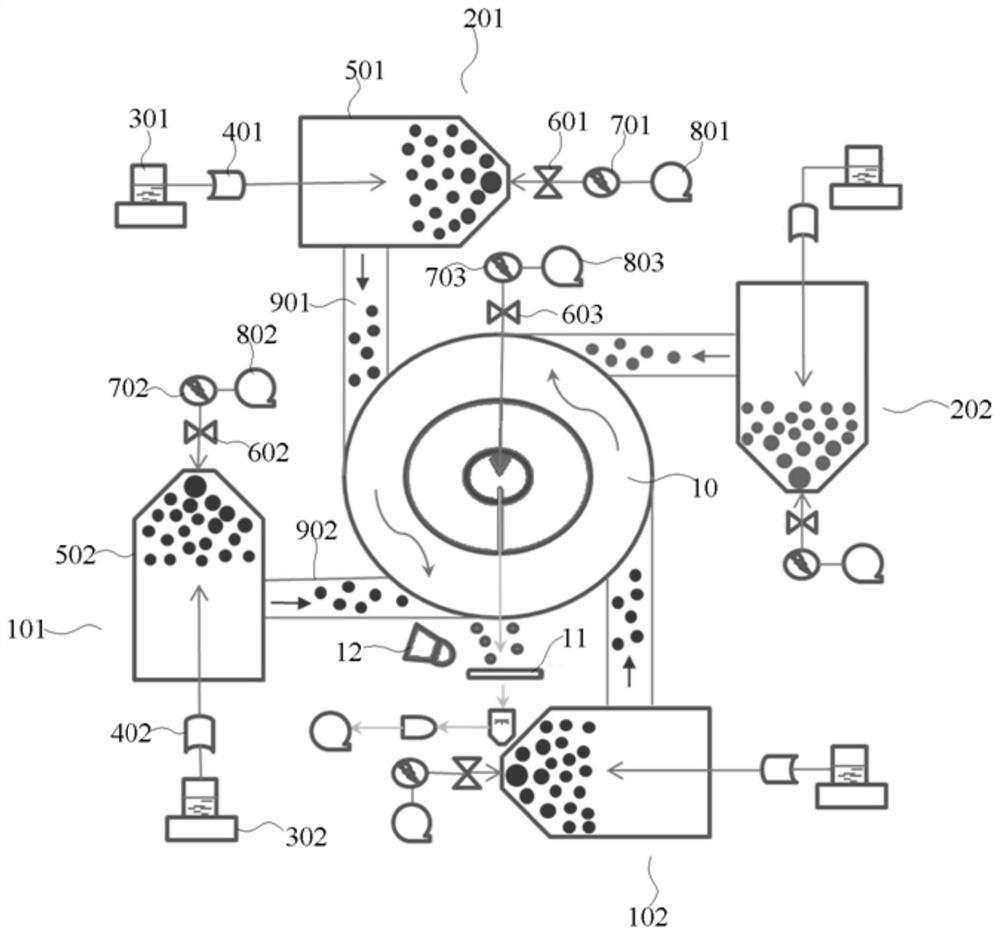

[0035] Such as figure 1 As shown, the nanoparticle flow is injected into the impingement flow reactor 10 through the nanoparticle injection system, and the coal-fired fly ash is injected into the impingement flow reactor 10 through the coal-fired fly ash injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com