Ultralow-temperature liquid hydrogen storage pressure vessel interlayer space vacuumizing method and device

A pressure vessel, ultra-low temperature technology, applied in the field of vacuuming, can solve the problems of long-term vacuuming, increase production cost, power consumption, etc., to achieve the effect of ensuring vacuum degree, improving reliability, reducing time and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

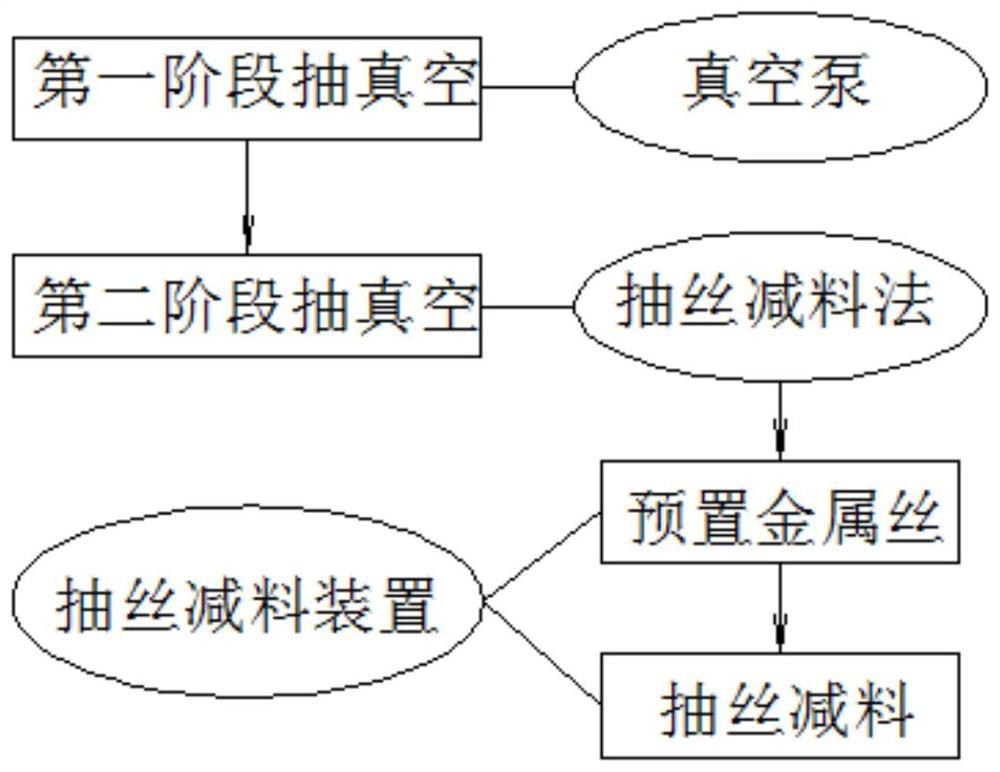

[0057] Such as Figures 1 to 7 Shown is an embodiment of a method for vacuuming the interlayer space of an ultra-low temperature liquid hydrogen storage pressure vessel according to the present invention, which sequentially includes the first stage of vacuuming the interior of the interlayer space 4 of the ultra-low temperature liquid hydrogen storage pressure vessel 1 by using a vacuum pump and adopting vacuum pumping. The second-stage vacuuming of the interlayer space of the ultra-low temperature liquid hydrogen storage pressure vessel by the wire-reducing method; in the second-stage vacuuming, the vacuuming steps of the wire-reducing method are as follows:

[0058] (1) Pre-installed metal wire: in the manufacturing stage of the ultra-low temperature liquid hydrogen storage pressure vessel 1, an ultra-long metal wire 5 with a certain volume and weight is placed in the interlayer space 4 of the ultra-low temperature liquid hydrogen storage pressure vessel 1 in advance, At the...

Embodiment 2

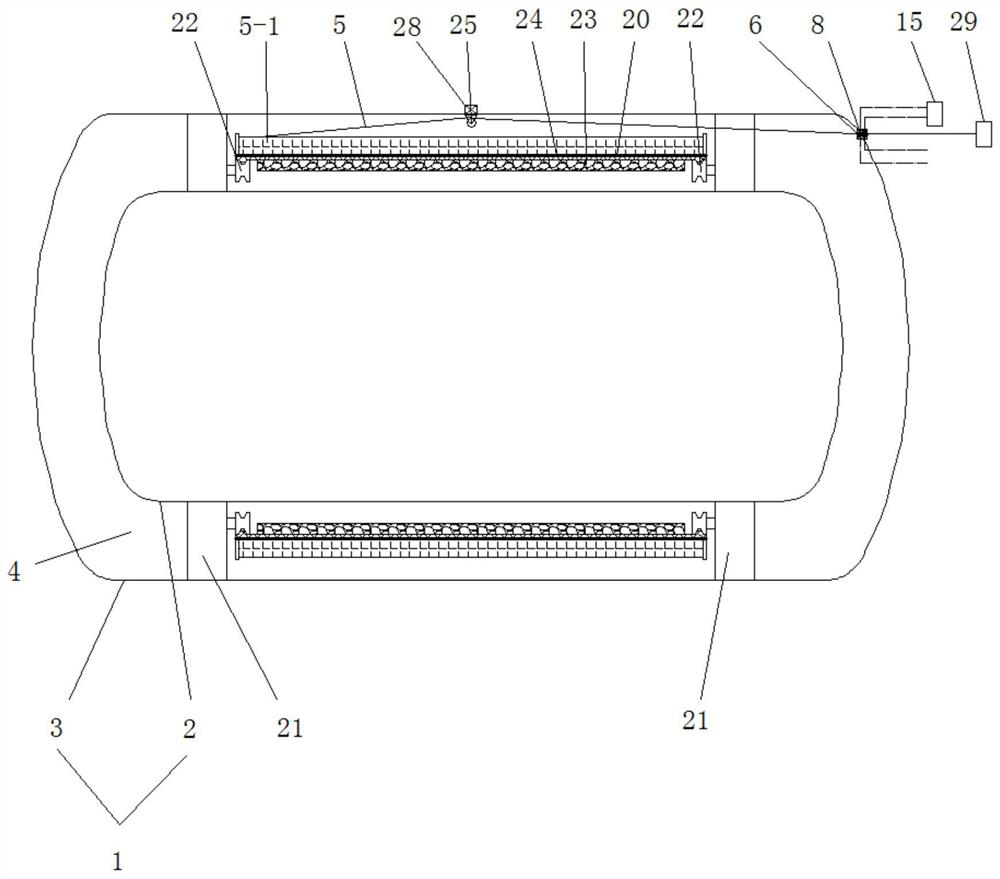

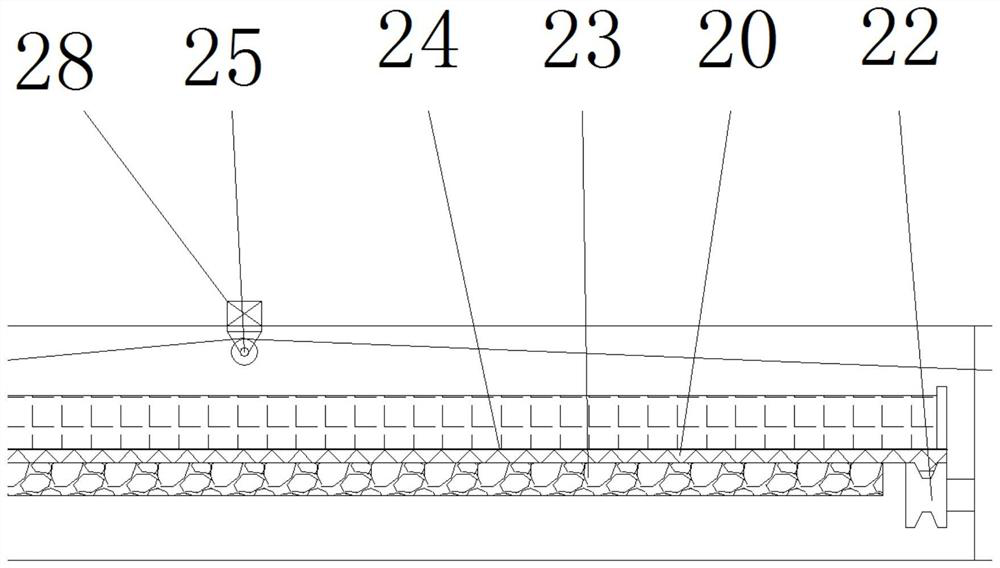

[0085] A device for vacuuming the interlayer space of an ultra-low temperature liquid hydrogen storage pressure vessel, comprising a metal wire 5 built into the interlayer space 4 of the ultra-low temperature liquid hydrogen storage pressure vessel 1 during the manufacturing stage of the ultra-low temperature liquid hydrogen storage pressure vessel 1, and a metal wire 5 arranged in the interlayer space 4 of the ultra-low temperature liquid hydrogen storage pressure vessel 1. The micro-perforation 6 on the outer container 3 of the ultra-low temperature liquid hydrogen storage pressure vessel 1, the wire drawing device 29 arranged outside the outer container 3, and one end of the metal wire 5 passes through the interlayer space 4. After passing through the micro-perforation 6, it protrudes to the outside of the tank wall of the outer container 3, and an interference sealing fit is formed between the metal wire 5 and the micro-perforation 6 by wire drawing, and the metal wire 5 pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com