Construction method of large-particle-size cement regenerated base pavement structure

A technology of pavement structure and construction method, which is applied in the direction of roads, roads, and cohesive pavement paved on site, etc., which can solve the problems of low anti-heavy load performance, subsidence, and easy cracking of flexible base layers, and achieve excellent bearing capacity , improve composition, reduce the effect of horizontal shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] This embodiment is a two-lane provincial road reconstruction project, the old road is a cement concrete pavement with a width of 7m, and the asphalt concrete pavement is used after the transformation.

[0039] After comprehensive treatment of the old cement pavement panel, it will be used as a cushion layer for the new pavement structure layer, and then 16-20cm6% cement stabilized graded macadam base + 18cm large particle size cement regeneration base + 8cmATB30 modified asphalt macadam underlayer + 4cm AC-13C imported asphalt concrete (diabase) upper layer.

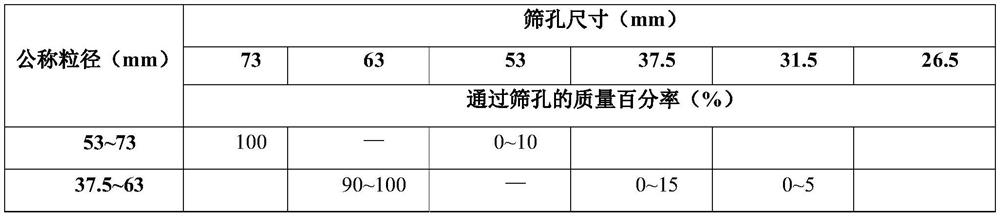

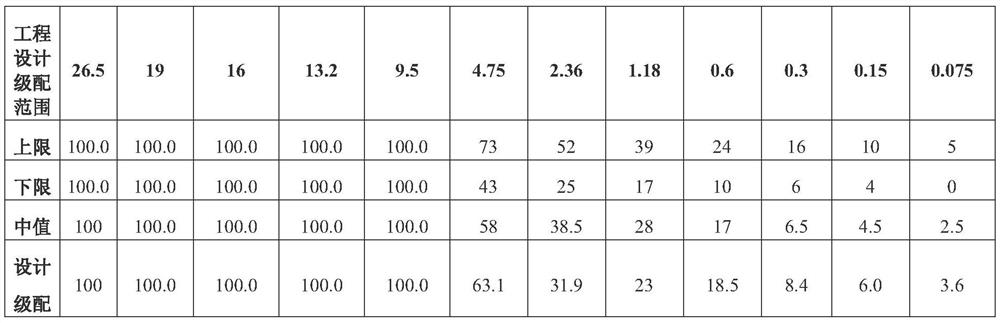

[0040] The 18cm large particle size cement regeneration base uses large particle size gravel with a nominal particle size of 37.5 to 63 as the main aggregate; after milling the old asphalt surface layer, sieve out the milling material with a particle size of less than 16mm, and use the The old road asphalt pavement milling material with P.C32.5R cement and water is mixed in the recycling equipment to form the ceme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com