High-strength and high-toughness low-alloy cast steel and preparation method thereof

A low-alloy cast steel, high-strength and toughness technology, applied in the field of cast steel materials, to achieve the effects of fine grain refinement, inhibition of growth, and improvement of toughness and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a high-strength toughness low-alloy cast steel and its manufacturing method. Its components and their mass percentages are: 0.22%C, 0.7%Si, 0.77%Mn, 1.05%Cr, 0.57%Mo, 0.54% %Ni, 0.05%V, 0.03%Nb, 0.02%Ti, 0.03%Cu, 0.004%P, 0.008%S, and the balance is Fe. (S and P originate from industrial pure iron containing trace amounts of S and P elements)

[0024] Preparation process: The mold is reserved at 200°C for 30 minutes, put into the vacuum melting furnace, and the raw materials are prepared according to the composition. The raw materials selected for this experiment are shown in Table 1, where the meaning of purity is: the content of the target element.

[0025] Table 1. Alloy type and purity

[0026]

[0027] Casting mold is 70kg, according to the composition of design, carry out batching, in embodiment 1, the quality of every kind of raw material is as shown in table 2:

[0028] Table 2. Alloy type and quality

[0029]

[0030] Melting p...

Embodiment 2

[0036] This embodiment provides a high-strength toughness low-alloy cast steel and its manufacturing method. Its components and their mass percentages are: 0.21% C, 0.52% Si, 0.72% Mn, 0.70% Cr, 0.53% Mo, 0.60 %Ni, 0.05% V, 0.02% Nb, 0.02% Ti, 0.02% Al, 0.03% Cu, the balance being Fe. 0.005% S, 0.007% P.

[0037] The manufacturing method is basically the same as in Example 1. The performance test of the prepared high-strength toughness low-alloy cast steel shows that the tensile strength is 1262MPa, the yield strength is 1162MPa, the elongation is 14.67%, the elongation after fracture is 35.00%, and the impact energy is 52J.

Embodiment 3

[0039]This embodiment provides a high-strength toughness low-alloy cast steel and its manufacturing method. Its components and their mass percentages are: 0.17%C, 0.50%Si, 0.86%Mn, 0.71%Cr, 0.67%Mo, 0.52% %Ni, 0.05% V, 0.03% Nb, 0.02% Ti, 0.01% Al, 0.03% Cu, the balance being Fe. 0.007% S, 0.004% P.

[0040] The manufacturing method is basically the same as in Example 1. The performance test of the prepared high-strength toughness low-alloy cast steel shows that the tensile strength is 1210MPa, the yield strength is 1121MPa, the elongation is 14.78%, the elongation after fracture is 37.56%, and the impact energy is 50J.

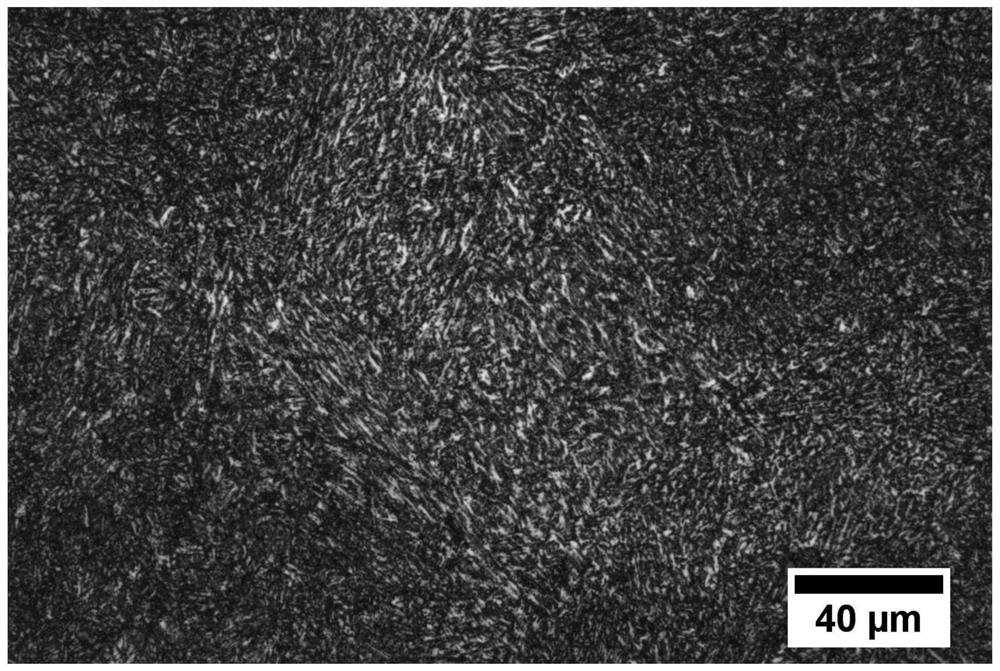

[0041] After heat treatment, such as figure 1 It is the metallographic image enlarged 500 times of Example 1, and the structure is tempered sorbite structure. In the process of austenitization, due to the addition of Nb, V, Ti and other alloying elements in the alloy composition, it plays a role in refining the austenite grains. At the same time, during th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com