Method and device for continuously treating high-concentration organic wastewater through multi-stage rotating wheel

A technology of continuous rotary and organic wastewater, applied in separation methods, water/sewage treatment, chemical instruments and methods, etc., can solve the problem that treatment technology and equipment are difficult to scale up, affect the normal process of water treatment, and it is difficult to realize wastewater treatment Continuity and other issues to achieve the effect of promoting uninterrupted rapid degradation and improving processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

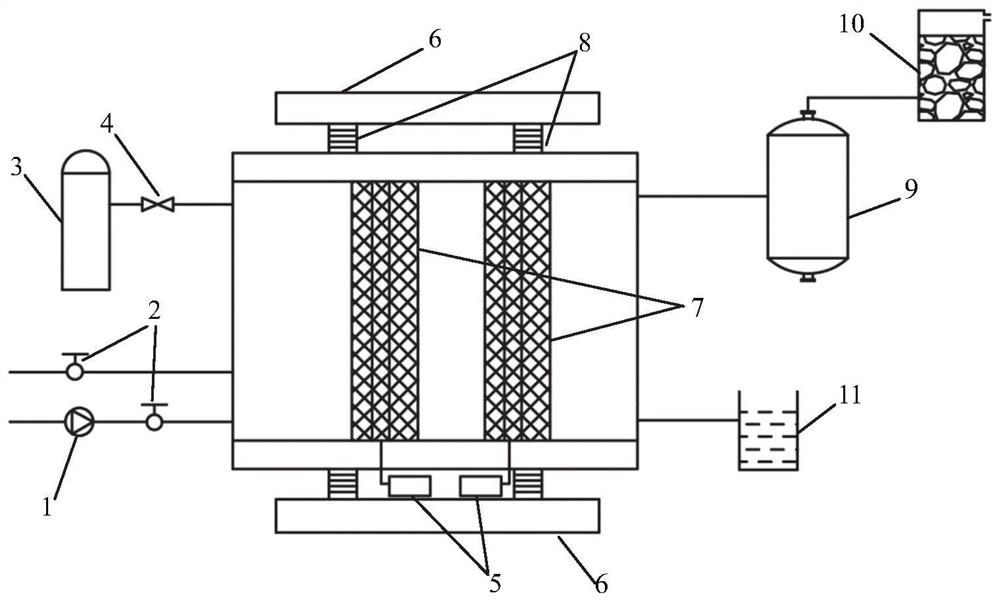

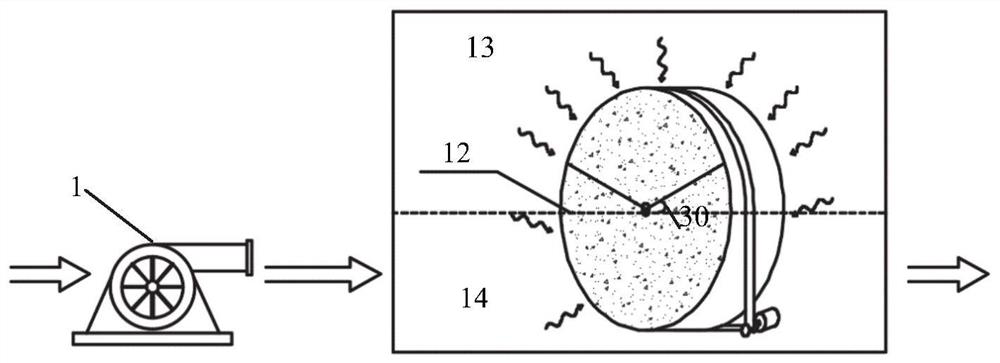

[0040]A device for continuously treating high-concentration organic wastewater with multi-stage runners, comprising: a wastewater processor with a cavity structure; a runner 7, which is vertically arranged inside the wastewater processor, and the inside of the runner 7 is filled with A wave-absorbing medium, the wave-absorbing medium is an activated carbon composite material loaded with metal oxides, and the metal oxides are Ni 2 o 3 , MnO 2 or Co 2 o 3 A mixture of one or more of them; the microwave generator 6 is respectively arranged at the top and bottom of the waste water processor.

[0041] The runner 7 is connected with the drive motor 5 to make the runner 7 rotate. The microwave generator is connected to the waveguide 8, and the waveguide 8 is connected to the waste water processor. The microwave energy is generated by the microwave generating device and transmitted to the waste water oxidation treatment equipment through the waveguide 8. It is used for the oxidati...

Embodiment 2

[0050] 1. Wastewater pretreatment: use a high-efficiency filter to filter out impurities and suspended particles in the wastewater, and adjust the pH value between 5-8, and add an appropriate amount of 30% hydrogen peroxide according to the initial measurement of wastewater COD and other indicators;

[0051] 2. Activated carbon pretreatment: configure a certain concentration of Ni 2 o 3 or MnO 2 or Co 2 o 3 Metal oxide solution, under the condition of stirring, add a certain weight of fruit shell activated carbon according to the proportion of the solution volume for impregnation, and then roast, the treated activated carbon is bundled with wire mesh, and the whole is put into the runner of the wastewater treatment equipment ;

[0052] After completing the assembly of the runner and the pretreatment of wastewater, it officially enters the microwave-induced catalytic oxidation process of wastewater

[0053] 3. Turn on the wastewater feed pump 1, inject it into the oxidatio...

Embodiment 3

[0062] The specific process of step 2 is: configure a certain concentration of Ni 2 o 3 , MnO 2 、Co 2 o 3 Metal oxide solution, under the condition of stirring, add a certain weight of fruit shell activated carbon according to the proportion of the solution volume for impregnation, and then roast, the treated activated carbon is bundled with wire mesh, and the whole is put into the runner of the wastewater treatment equipment .

[0063] Wherein, in step 6, the rotating speed of the runner is 25 r / d.

[0064] In step 9, the concentration of organic gas in the tail gas is 5PPM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com