Method for replacing and repairing underground water of in-situ leaching uranium mining base by adopting sewage pumping and clean water injection

A technology for mining uranium and groundwater by in-situ leaching, which is applied in the field of groundwater treatment and can solve problems such as groundwater pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

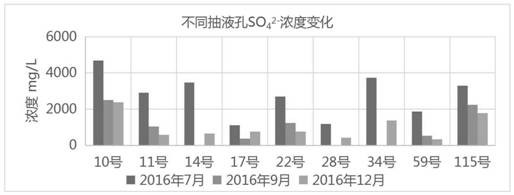

[0058] The in-situ leaching uranium mining base is preferably located in the 38-1 ore section of the area under the jurisdiction of Hongdou Village, north of Chengzimen, Mangbang Township. The in-situ leaching well site includes 257 boreholes, 25,300 square meters of polluted groundwater, and polluted ground 11843 square meters, 3004.8 square meters of polluted buildings and polluted equipment.

[0059] The first stage: the single-pumping cleaning and rapid degradation technology is adopted, only pumping without injection. During the implementation period, according to the requirements of the design plan and the actual situation on site, 38 boreholes with large water volume were selected from the 116 available boreholes as the overall situation Pumping drilling, the total pumping volume is 180m 3 / d. By pumping liquid, in order to form a falling funnel within the scope of groundwater pollution, the groundwater outside the scope of pollution enters the scope of the funnel. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com