Hot runner zinc spraying device for power transmission line steel tube tower

A technology for power transmission lines and steel pipe towers, which is applied to the field of hot runner zinc spraying devices for steel pipe towers of power transmission lines, can solve the problems of slow film wrapping efficiency, increase production process, reduce efficiency, etc., and achieve the improvement of wrapping film efficiency and the saving of procedures. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

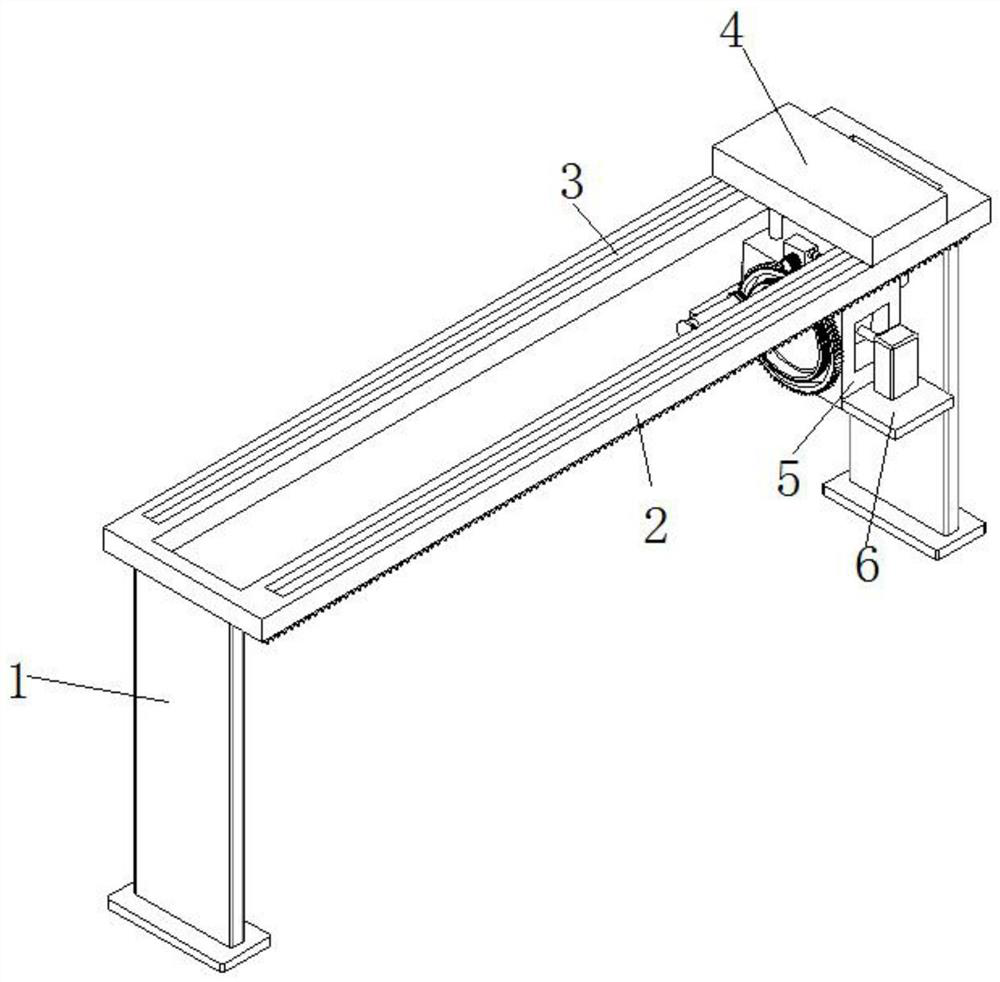

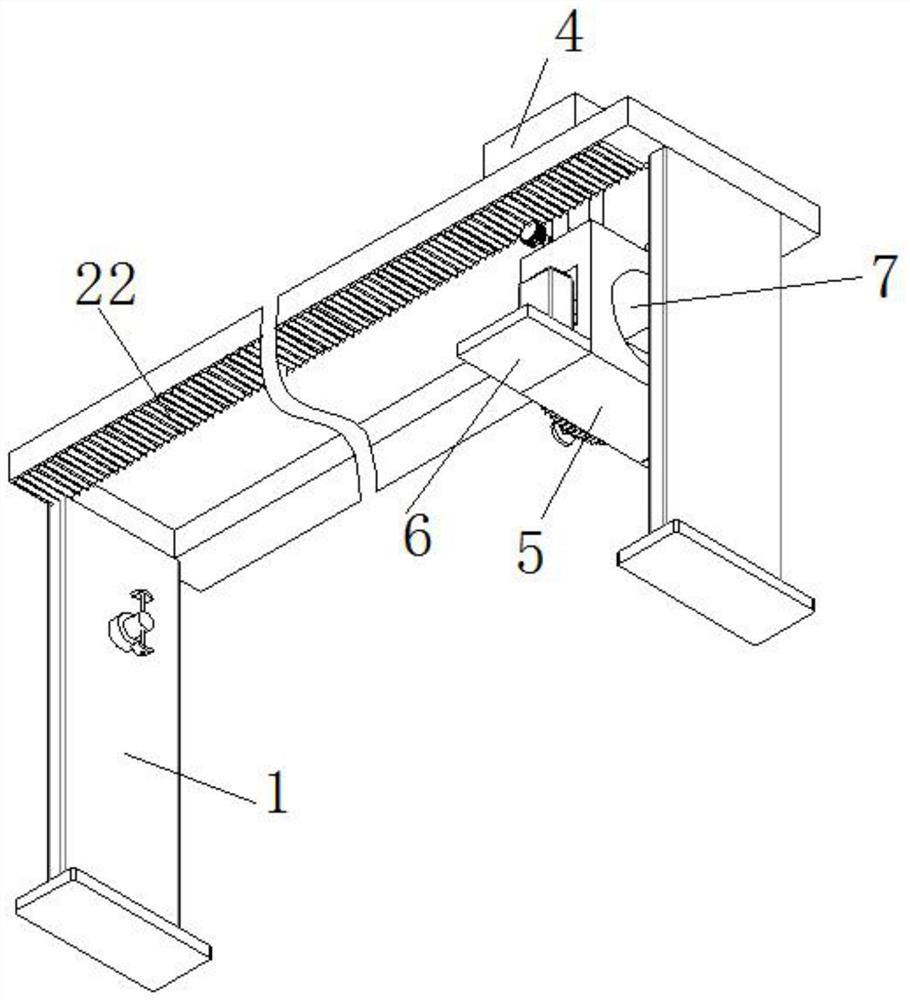

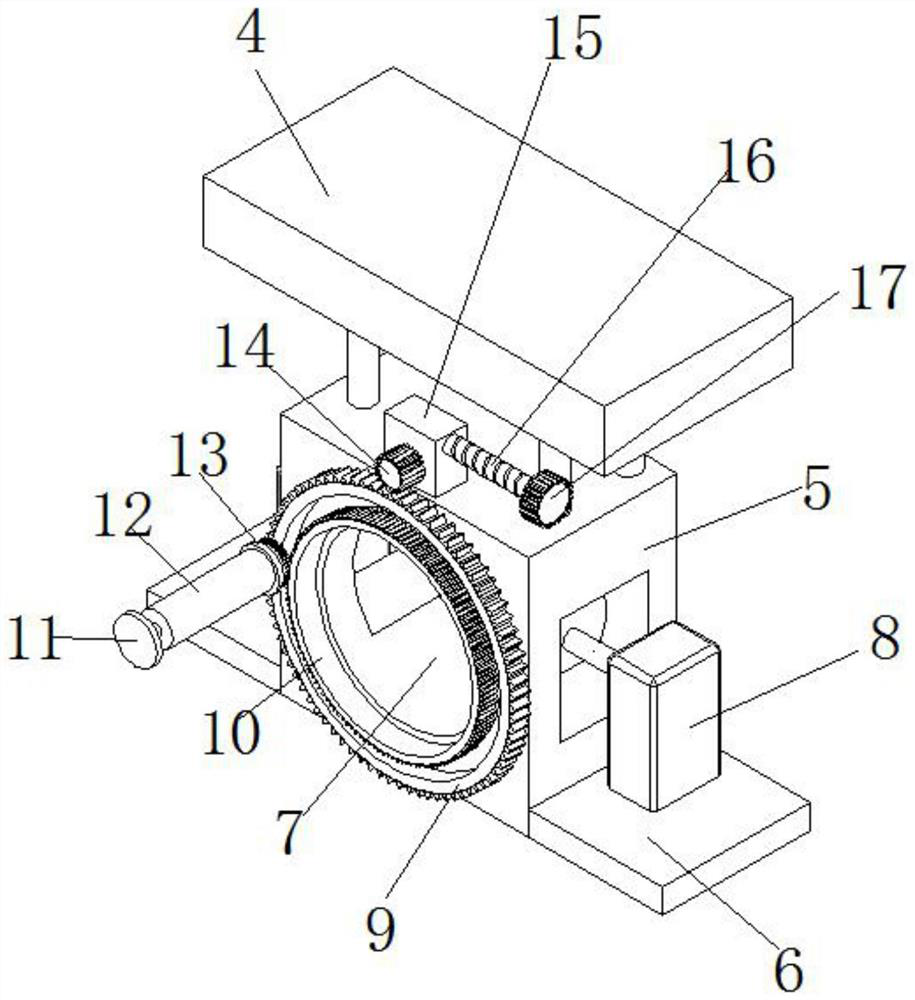

[0024] refer to Figure 1-4 , a hot runner zinc spraying device for a steel pipe tower of a transmission line, including two vertical stands 1, the upper parts of the two stand 1 relatively close to one side are equipped with a steel pipe clamping mechanism, and the upper ends of the two stand 1 are horizontal A rectangular frame 2 is welded, and the upper end of the rectangular frame 2 is slid to be provided with a slide plate 4, a sliding mechanism is provided between the slide plate 4 and the rectangular frame 2, vertical bolts are fixed on the four corners of the lower part of the slide plate 4 with columns, and the lower ends of the four columns A moving seat 5 is welded, and the moving seat 5 runs through the outer walls of both vertical sides and has a passage opening 7. Both sides of the moving seat 5 are equipped with zinc spraying components. Ring 9, the rotating gear ring 9 rotates horizontally at one end away from the moving seat 5 and is provided with a rotating r...

Embodiment 2

[0028] refer to Figure 1-2and 4-5, a hot runner zinc spraying device for a steel pipe tower of a transmission line, including two vertical stands 1, the upper parts of the two stand 1 are relatively close to the side of the steel pipe clamping mechanism, and the two vertical A rectangular frame 2 is horizontally welded on the upper end of the frame 1, and a sliding plate 4 is provided on one end of the upper part of the rectangular frame 2, and a sliding mechanism is provided between the sliding plate 4 and the rectangular frame 2, and the four corners of the lower part of the sliding plate 4 are fixed with uprights by vertical bolts, and The lower ends of the four columns are welded with a moving seat 5, the moving seat 5 runs through the outer walls on both sides of the vertical and has a passage opening 7, both sides of the moving seat 5 are equipped with zinc spraying components, and the outer wall of the moving seat 5 rotates around the passage opening 7 A rotating gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com