Hidden hollowed-out aluminum plating pattern holographic anti-counterfeiting adhesive tape and manufacturing method thereof

A technology of holographic anti-counterfeiting and production method, which is applied in the field of hidden hollow-out aluminum-plating pattern holographic anti-counterfeiting tape and its production, can solve the problems of design and production troubles, cost loss, weakening of anti-counterfeiting characteristics of refined hollow-aluminum plating technology, etc. The effect of stable quality, improved adhesion and tightness, and improved anti-counterfeiting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

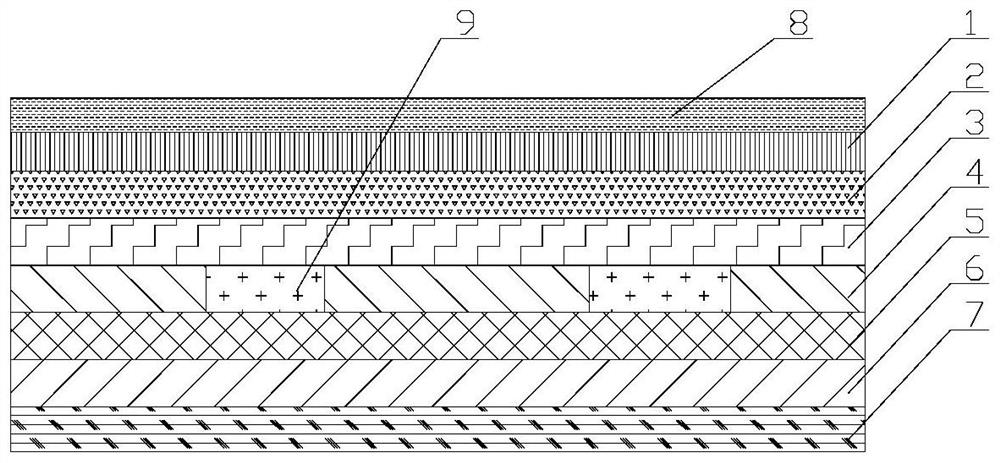

[0056] 1) Select BOPET film as the base film layer 1;

[0057] 2) Apply a silicone oil release agent on the back of the base film layer 1 as the release layer 8;

[0058] 3) coating the imprint coating 2 on the base film layer, and drying;

[0059] Embossing coating 2 is a thermoplastic acrylic resin composite coating, and the coating dry weight is 1.0g / m 2 , the drying temperature is 100-130°C (5 groups of ovens, the temperature settings are: 100°C, 110°C, 130°C, 120°C, 100°C), and the drying time is 8s.

[0060] 4) Embossing a holographic information pattern on the embossing coating 2 to form a holographic information layer 3;

[0061] 5) On the holographic information layer 3, use a printing plate roller to print a perfluoropolyether layer as the shielding layer 9. The shielding layer 9 partially covers the holographic information layer 3, and the shielding layer 9 is dried in an instant and then aluminum-plated. The holographic information layer 3 The part of the shield...

Embodiment 2

[0074] 1) Select BOPP film as the base film layer 1;

[0075] 2) Coating a non-silicone oil release agent on the back of the base film layer 1 as the release layer 8;

[0076] 3) coating the imprint coating 2 on the base film layer 1, and drying;

[0077] Embossing coating 2 is a thermoplastic acrylic resin composite coating with a dry coating weight of 1.2g / m 2 , the drying temperature is 100-130°C (5 groups of ovens, the temperature settings are: 100°C, 110°C, 130°C, 120°C, 100°C), and the drying time is 10s.

[0078] 4) Embossing a holographic information pattern on the embossing coating 2 to form a holographic information layer 3;

[0079] 5) On the holographic information layer 3, use a printing plate roller to print a perfluoropolyether layer as the shielding layer 9. The shielding layer 9 partially covers the holographic information layer 3, and the shielding layer 9 is dried in an instant and then aluminum-plated. The holographic information layer 3 The part of the ...

Embodiment 3

[0089] 1) Select BOPP film as the base film layer 1;

[0090] 2) Coating a non-silicone oil release agent on the back of the base film layer 1 as the release layer 8;

[0091] 3) coating the imprint coating 2 on the base film layer 1, and drying;

[0092] Embossing coating 2 is a cellulose acetate embossing transfer coating with a dry weight of 1.0g / m 2 , the drying temperature is 80-110°C (5 groups of ovens, the temperature settings are: 80°C, 90°C, 110°C, 100°C, 90°C), and the drying time is 8s.

[0093] 4) Embossing a holographic information pattern on the embossing coating 2 to form a holographic information layer 3;

[0094] 5) On the holographic information layer 3, use a printing plate roller to print a perfluoropolyether layer as the shielding layer 9. The shielding layer 9 partially covers the holographic information layer 3, and the shielding layer 9 is dried in an instant and then aluminum-plated. The holographic information layer 3 The part of the shielding laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com