A kind of high-strength hordein-chitosan composite film and preparation method thereof

A technology of hordein and chitosan, which is applied in the field of food preservation, can solve problems such as cross-linking strength measurement, and achieve the effects of low production cost, easy promotion and use, and excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1, a kind of preparation method of high strength hordein chitosan composite film

[0048] The preparation method comprises the following steps:

[0049] S1. Extraction of hordein: barley seeds were ground into powder using a grinder, and then stirred continuously with n-hexane at a ratio of 5:1 (v / w) for 2 h at 25 °C. The homogenate was centrifuged in a high-speed refrigerated centrifuge at 25°C, 2000×g for 5 min. The precipitate obtained was washed once by centrifugation with ultrapure water and 0.1 M sodium chloride solution, respectively. The above precipitate was dispersed in 75% (v / v) ethanol aqueous solution according to the ratio of solvent to barley flour 10:1 (v / w), and stirred at 55 °C for 2 h at 500 rpm. The supernatant was collected by centrifugation, centrifuged at 4000×g for 5 min, and residual ethanol was removed using a rotary evaporator at 45°C. Samples were freeze-dried in a freeze dryer for 48 h, and the dry powder was stored in plastic ...

Embodiment 2

[0054] Embodiment 2, hordein chitosan composite film characterization

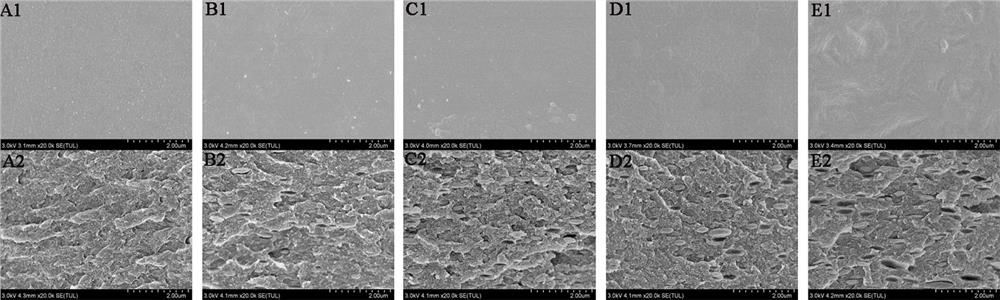

[0055] To further analyze the obtained composite film, the hordein-chitosan composite film was first fixed on the aluminum support with double-sided carbon tape, and coated with a layer of fine gold-palladium layer, using scanning electron microscope, at the acceleration of 3Kv Voltage, working distance of 10.9~11.7mm and magnification of 10,000 times were used to observe the surface morphology of the film, and it was found that the chitosan film ( figure 1 Middle A) The surface cracks are small, and the rice grains have more protrusions; the composite film obtained by mixing hordein and chitosan at a ratio of 1:3 ( figure 1 Middle B) The surface has large protrusions and small pores; a composite film obtained by mixing hordein and chitosan at a ratio of 1:5 ( figure 1 Middle C) There are slight streaks on the surface, and the overall smoothness; the composite film obtained by mixing hordein and chitosan ...

Embodiment 3

[0058] Embodiment 3, the measurement of the thickness of hordein chitosan composite film and mechanical property

[0059] The thickness of the sample was measured with a digital micrometer, and 6 points were randomly selected around the composite film to calculate the average thickness. The tensile strength (TS) and elongation at break (EAB) of the composite film were measured by a physical property analyzer with an initial distance of 60 mm and a probe speed of 0.5 mm / s. The composite film was cut into strips of 20×80 mm, and each group was repeated at least 3 times. The calculation formulas of TS and EAB are as follows:

[0060] TS(MPa)=P / (b×d)

[0061] EAB(%)=(L-L 0 ) / L 0 ×100%

[0062] In the formula, P is the maximum force (N), b is the thickness (mm), and d is the film width (mm);

[0063] L is the length (mm) when the film breaks, L 0 is the initial length of the film (mm).

[0064] The thickness of the hordein / chitosan-based composite film was reduced compared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com