Engineering machinery cab surface treatment method

A technology for surface treatment and construction machinery, applied in the field of surface treatment of construction machinery cabs, can solve the problems of inability to ensure the safety of construction workers, poor ventilation and ventilation in the cab, and increased cab testing, so as to avoid direct impact extrusion. , easy to turn on and off, high-security effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

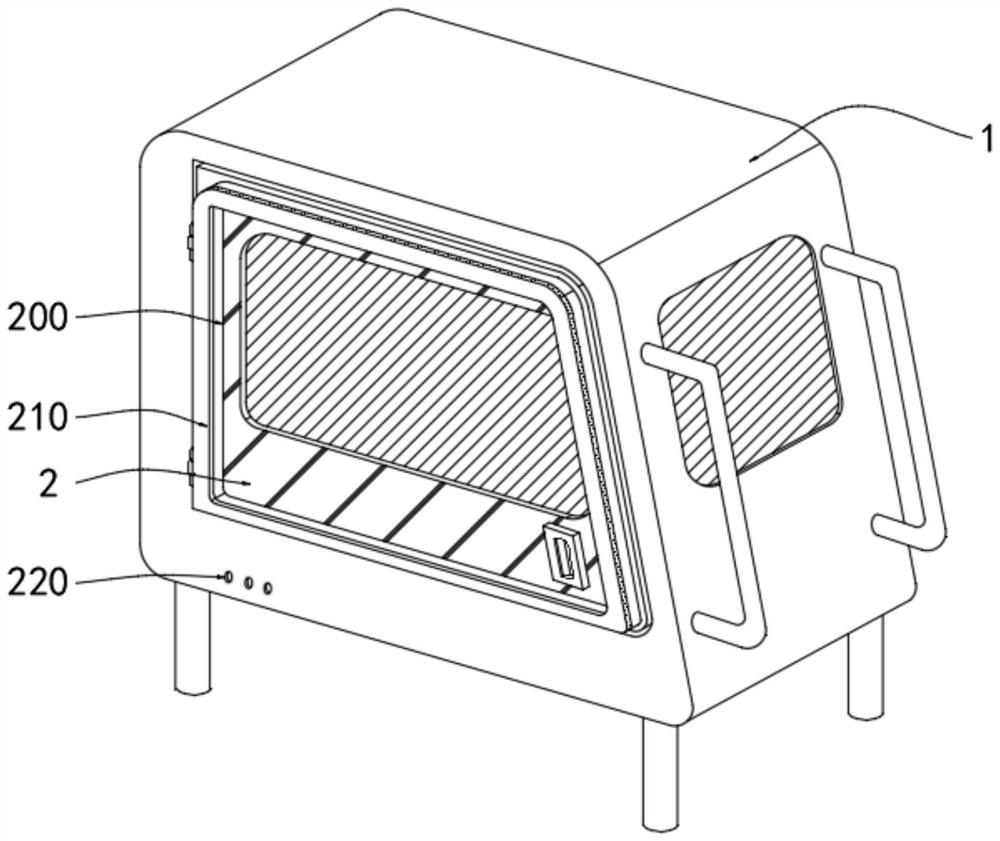

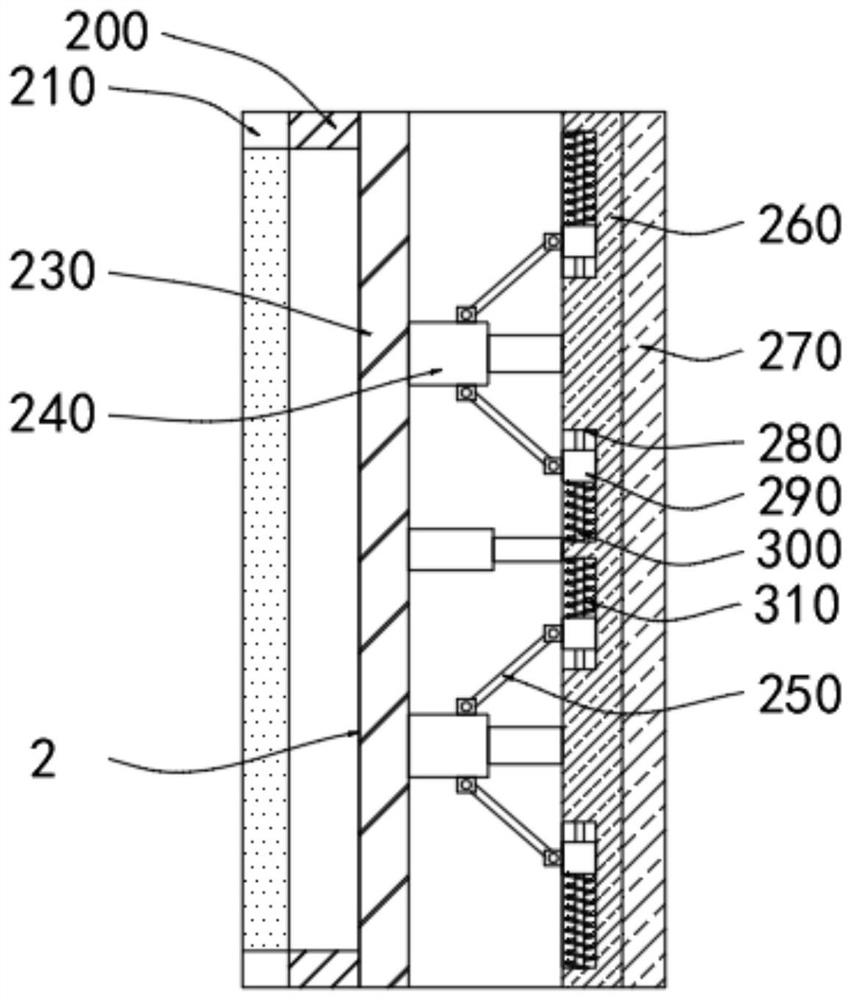

[0034] Both sides of the driver’s cab 1 are rotatably connected to the door 2 through pin shafts. The edge of the outer surface of the door 2 is fixedly connected with a protective ring 200. The surface of the protective ring 200 is matched with a backing plate 210. The door 2 consists of a steel plate. 260, one side of the steel plate 260 is pressed with an outer guard plate 230, and the other side of the steel plate 260 is provided with an inner protective PVC insulating plate 270, which adopts three layers of protection of the outer guard plate 230, the steel plate 260 and the inner protective PVC insulating plate 270 , can reduce the impact of factors of the external engineering environment on the warehouse door 2 .

[0035] The inside of the outer guard plate 230 and the steel plate 260 is provided with an anti-seismic buffer protection mechanism. The anti-seismic buffer protection mechanism includes a telescopic sleeve rod 240 arranged at the joint between the outer guard...

Embodiment 2

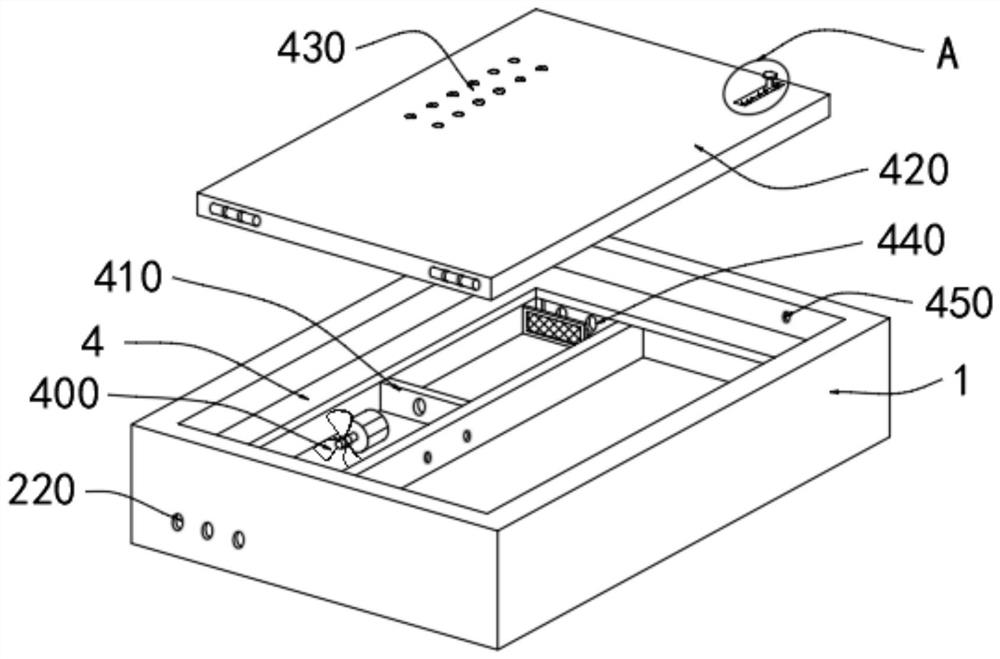

[0039] The bottom surface of the inner cavity of the driver's cab 1 is provided with a storage clean air chamber 4, which can place some equipment used in construction machinery. The blower fan 400 fixed at the bottom of the clean air chamber 4, one side of the blower fan 400 is provided with an air hole plate 410, the side surface of the storage clean air chamber 4 is provided with an exhaust hole 220, and the storage clean air chamber 4 The other side surface is provided with an outer air inlet 440, and the outer air inlet 440 is on the same straight line as the exhaust hole 220, and the top of the wall plate is provided with a sealing plate 420 connected with the storage clean air chamber 4 through a hinge, and the sealing The bottom surface of the plate 420 is provided with a clamp seat 460 matching the wall plate, the bottom surface of the clamp seat 460 is provided with a cavity 470, and the top surface of the sealing plate 420 is provided with an inner cavity 470 matchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com