Improved carbon black blending device for carbon black production

An improved carbon black technology, which is applied in transportation and packaging, mixers, cleaning methods and utensils, etc., can solve the problems of drifting and a large amount of materials adhered to the tank wall, and achieve the effect of preventing drifting and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

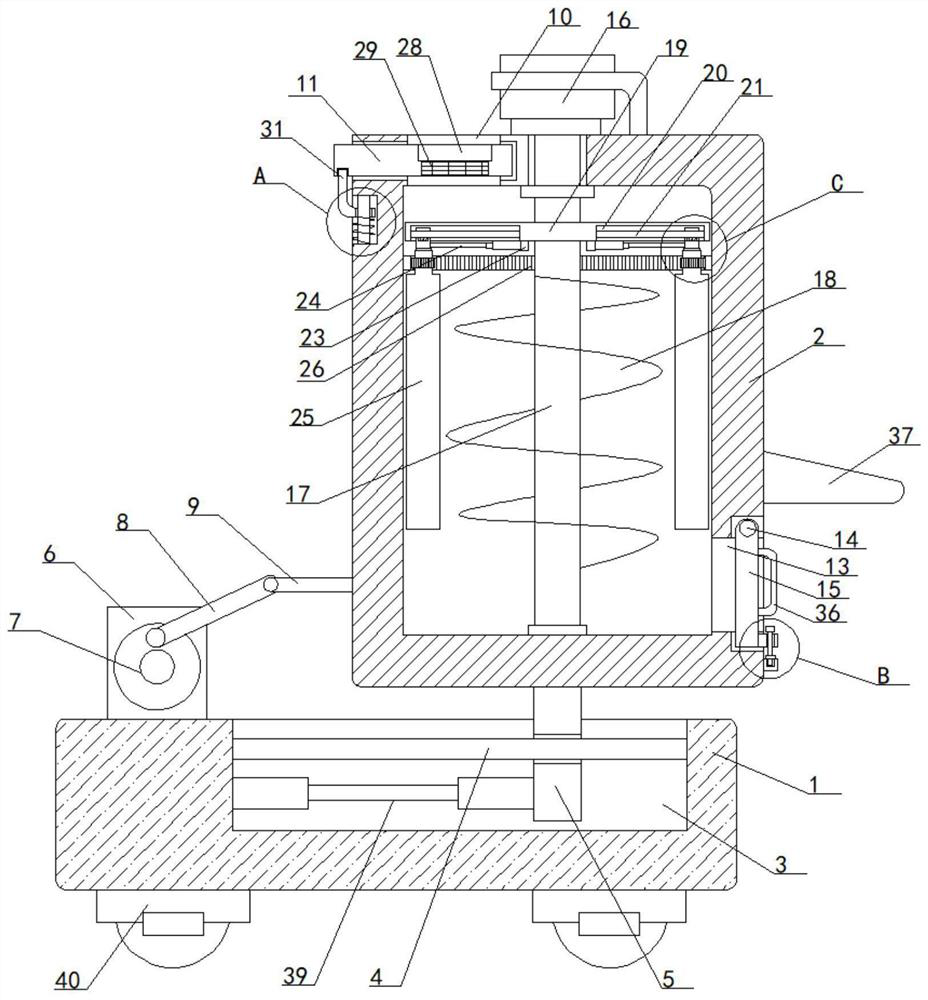

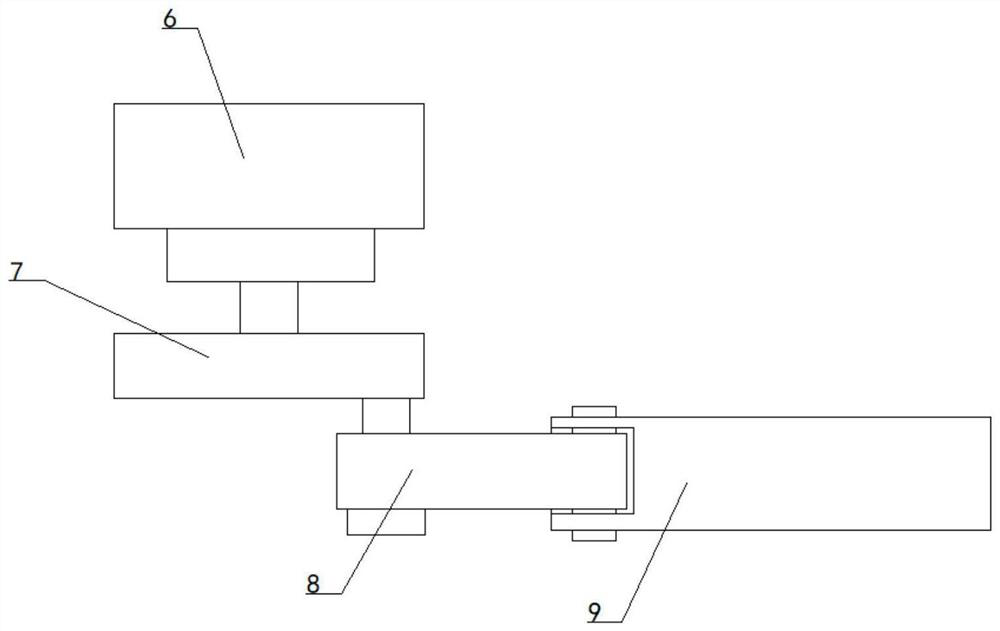

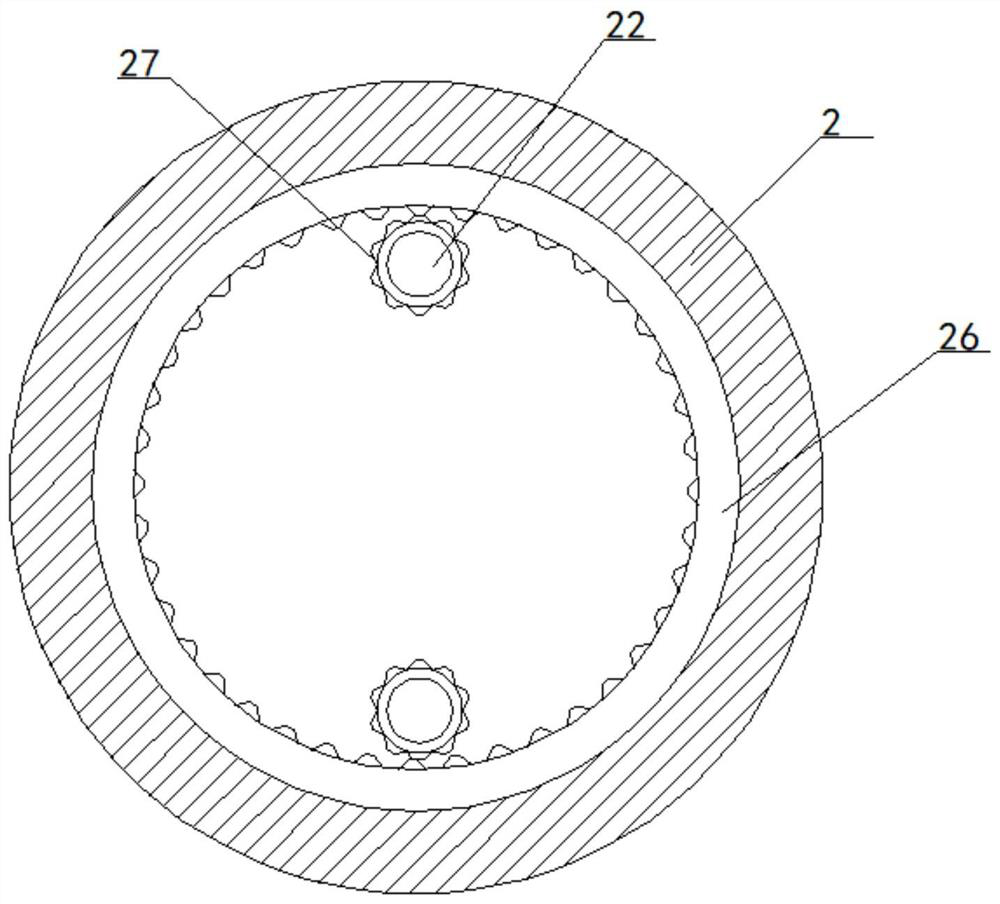

[0034] refer to Figure 1-6 , an improved carbon black remixing device for carbon black production, comprising a base 1 and a storage box 2, the bottom of the base 1 is rotatably connected with a plurality of universal self-locking wheels 40, which is convenient for moving the base 1, and the top of the base 1 is provided with There is a chute 3, and a slide bar 4 is fixedly connected in the chute 3 for supporting the slide block 5, and the slide bar 4 is slidably connected with a slide block 5, which is used to drive the storage box 2 to reciprocate, and the top of the slide block 5 It is fixedly connected to the bottom of the material storage box 2, and the slider 5 is connected to the inner wall of the chute 3 through a damping shock absorber 39, which plays a certain shock-absorbing and buffering effect on the slider 5. The top of the base 1 is fixedly connected to the first motor 6, It is used to drive the turntable 7 to rotate. The output end of the first motor 6 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com