Bolt

A bolt and screw technology, applied in the field of bolts in the crushed part, can solve problems such as damage to the thread surface of the internal thread, inability to place the bolt in place, and inability to fasten and connect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

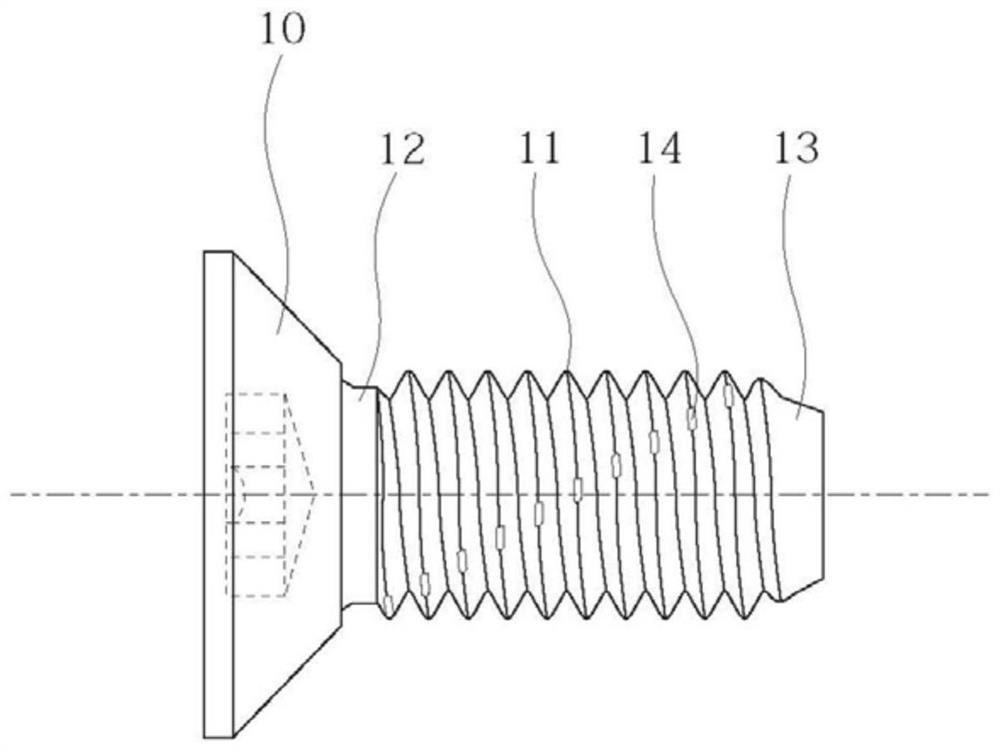

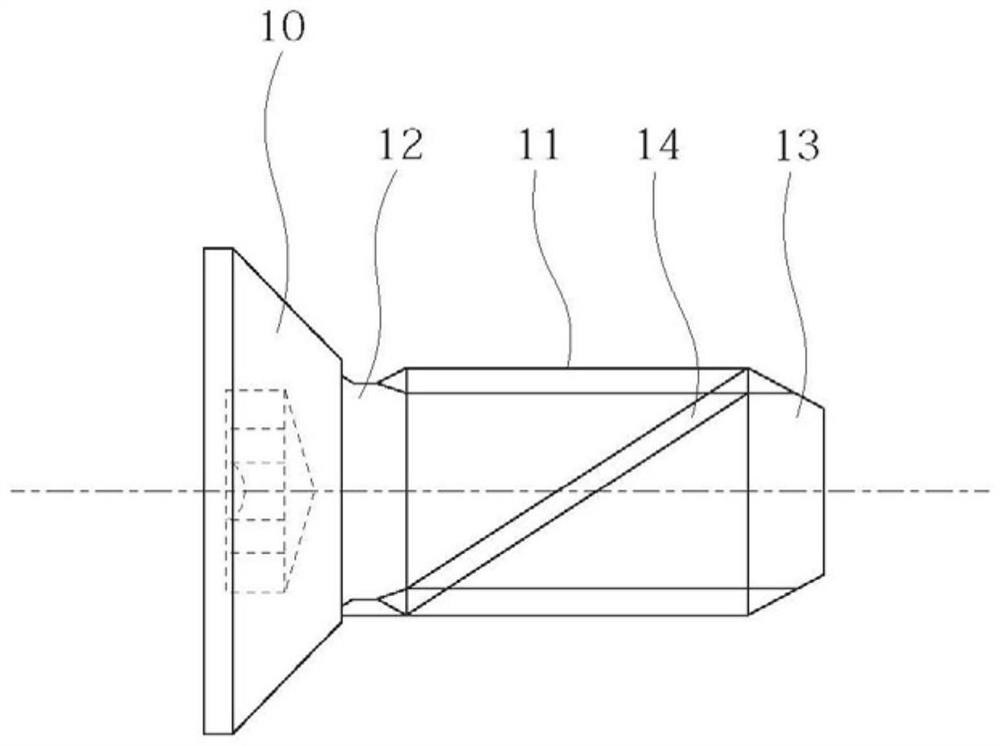

[0023] Preferred embodiments of the present invention are shown below. figure 1 It is a front view of the bolt of the embodiment, figure 2 is its explanatory diagram. In these figures, 10 is the head of the bolt, and 11 is a standard thread formed on the shaft by roll forming. The standard threaded portion 11 is formed over the entire length of the shaft except for the lower head portion 12 and the shaft front end portion 13 . This bolt is a right-handed threaded bolt in which the standard threaded portion 11 is provided with a right-handed thread, and advances forward when turned to the right with respect to the internal thread. In addition, in the present embodiment, a concave portion for receiving a tool is formed on the head 10 , but the shape of the head 10 is arbitrary, and may be a normal hexagon. In addition, the shape of the shaft front end portion 13 is not particularly limited.

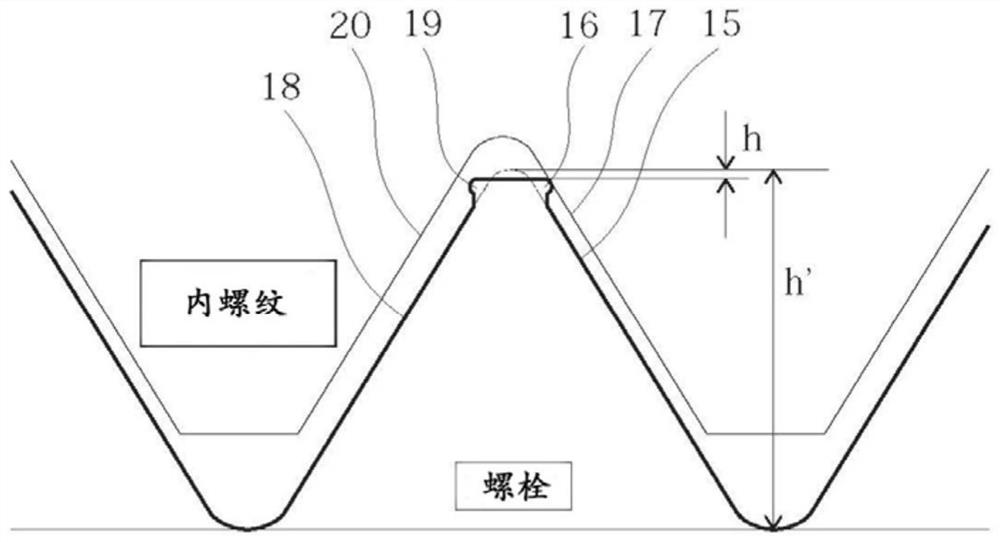

[0024] A crush portion 14 is formed on the thread of the standard thread portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com