Silicon carbide JBS device and manufacturing method thereof

A manufacturing method and technology of silicon carbide, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of sacrificing reverse performance, complicated process, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

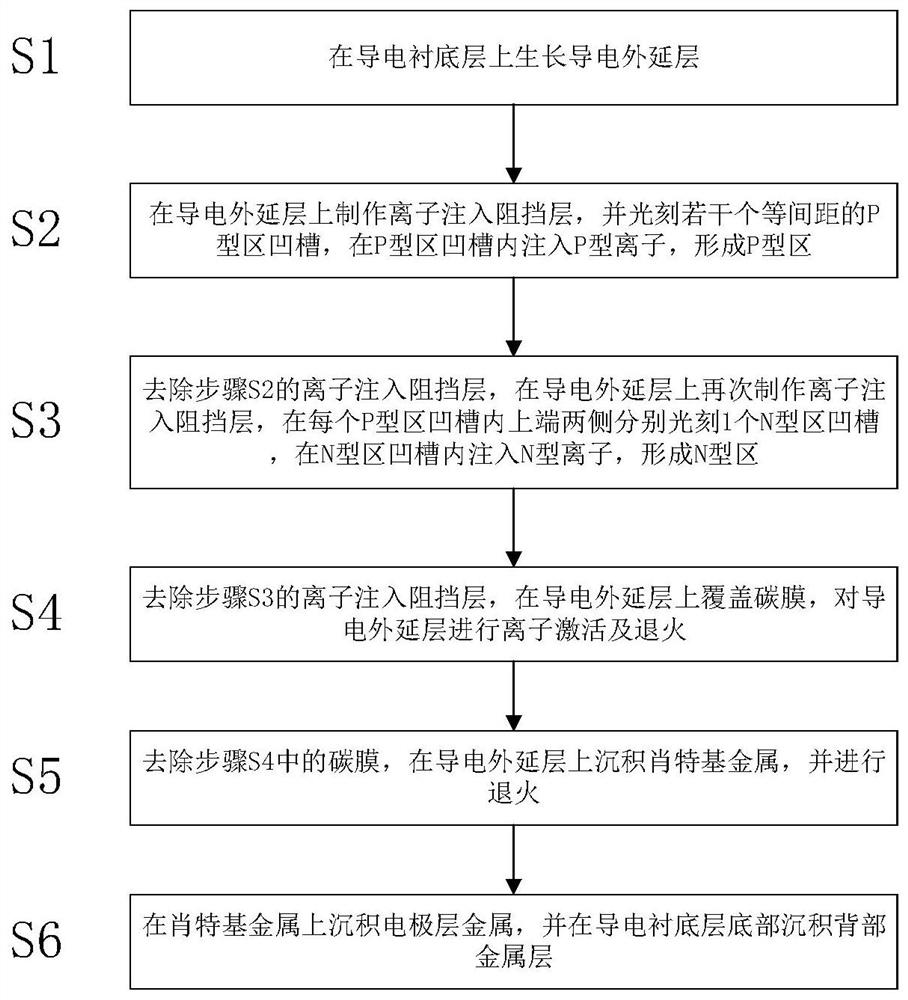

Method used

Image

Examples

Embodiment 1

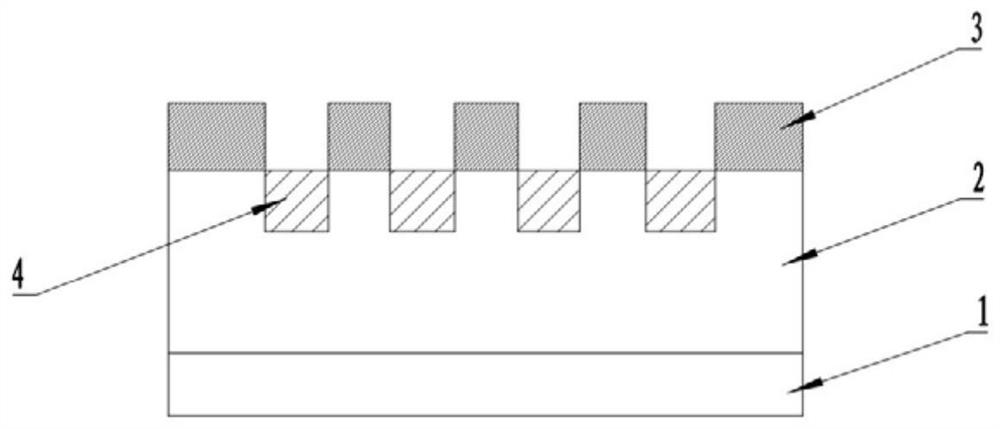

[0040] Such as Figure 5 As shown, a silicon carbide JBS device is disclosed in this embodiment, the device includes a conductive substrate layer 1 and a conductive epitaxial layer 2, the ion doping concentration of the conductive epitaxial layer 2 is 1e16cm-3, and the thickness of the conductive epitaxial layer 2 is 3 μm.

[0041] The conductive epitaxial layer 2 is provided with a P-type region 4 and an N-type region 5, and the P-type region 4 includes a plurality of equally spaced P-type region 4 grooves, and P-type ions are implanted in the P-type region 4 grooves. ; Both sides of the upper end of each P-type area 4 grooves are respectively provided with an N-type area 5 grooves, and N-type ions are injected into the N-type area 5 grooves, the P-type ions are aluminum ions, and the aluminum The ion implantation dose is 1e11cm-3, the N-type ions are nitrogen ions, and the nitrogen ion implantation dose is 5e11cm-3.

[0042] Schottky metal 6 is deposited on the upper part ...

Embodiment 2

[0051] This embodiment also discloses a silicon carbide JBS device, which differs from the first embodiment in that the ion doping concentration of the conductive epitaxial layer 2 in this embodiment is 1e18cm-3, and the thickness of the conductive epitaxial layer 2 is 52 μm. The P-type ions are aluminum ions, and the implantation dose of the aluminum ions is 1e13cm-3. The N-type ions are nitrogen ions, and the nitrogen ion implantation dose is 5e14cm-3. The electrode layer metal 7 is made of aluminum with a thickness of 5 μm, and the back metal layer 8 is made of nickel with a thickness of 3 μm.

[0052] This embodiment also discloses a silicon carbide JBS manufacturing method that is matched with the above-mentioned silicon carbide JBS device. The difference from Embodiment 1 is that in this embodiment,

[0053] S1: The ion doping concentration of the conductive epitaxial layer 2 is 1e18cm-3, and the thickness of the conductive epitaxial layer 2 is 52 μm.

[0054] S2: the ...

Embodiment 3

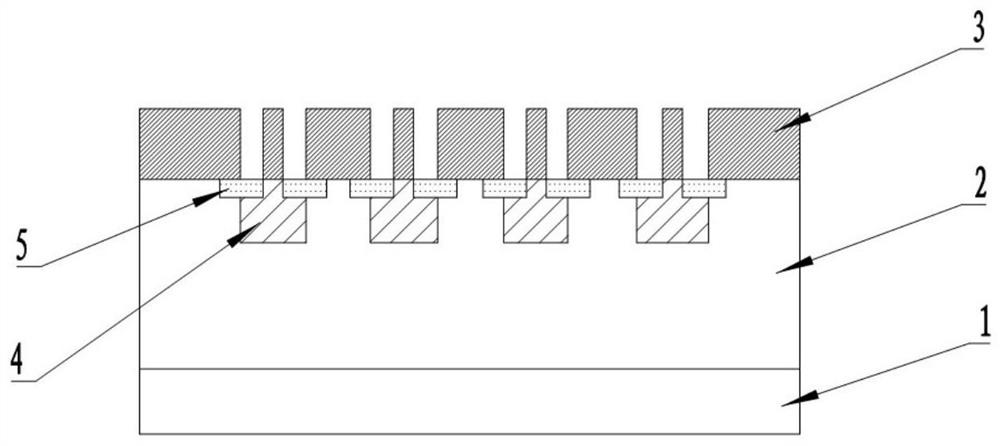

[0060] Such as Image 6 As shown, this embodiment also discloses a silicon carbide JBS device. The difference from Embodiment 1 is that this embodiment also includes a buffer layer, and the buffer layer is respectively connected to the conductive substrate layer 1 and the conductive epitaxial layer 2. , the buffer layer is N-type doped silicon carbide. The ion doping concentration of the conductive epitaxial layer 2 is 1e19cm-3, and the thickness of the conductive epitaxial layer 2 is 100 μm. The P-type ions are aluminum ions, and the implantation dose of the aluminum ions is 1e14cm-3. The N-type ions are nitrogen ions, and the nitrogen ion implantation dose is 1e15cm-3. The material of the electrode layer metal 7 is aluminum with a thickness of 7 μm, and the material of the back metal layer 8 is silver with a thickness of 4 μm.

[0061] This embodiment also discloses a silicon carbide JBS manufacturing method that is matched with the above-mentioned silicon carbide JBS dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com