Indoor performance test method for applying gravel polymer porous material to sponge city

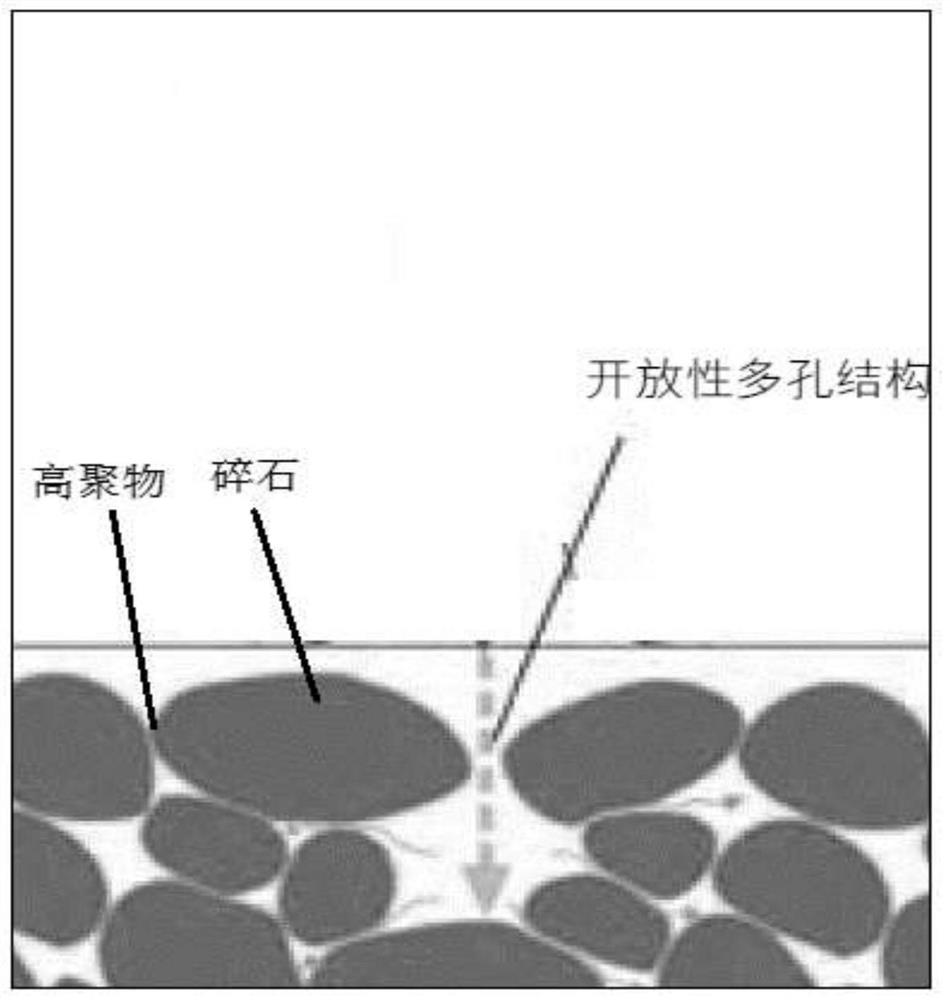

A sponge city and porous material technology, applied in the direction of suspension and porous material analysis, analysis materials, preparation of test samples, etc., to achieve the effect of easy realization and uniform internal pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

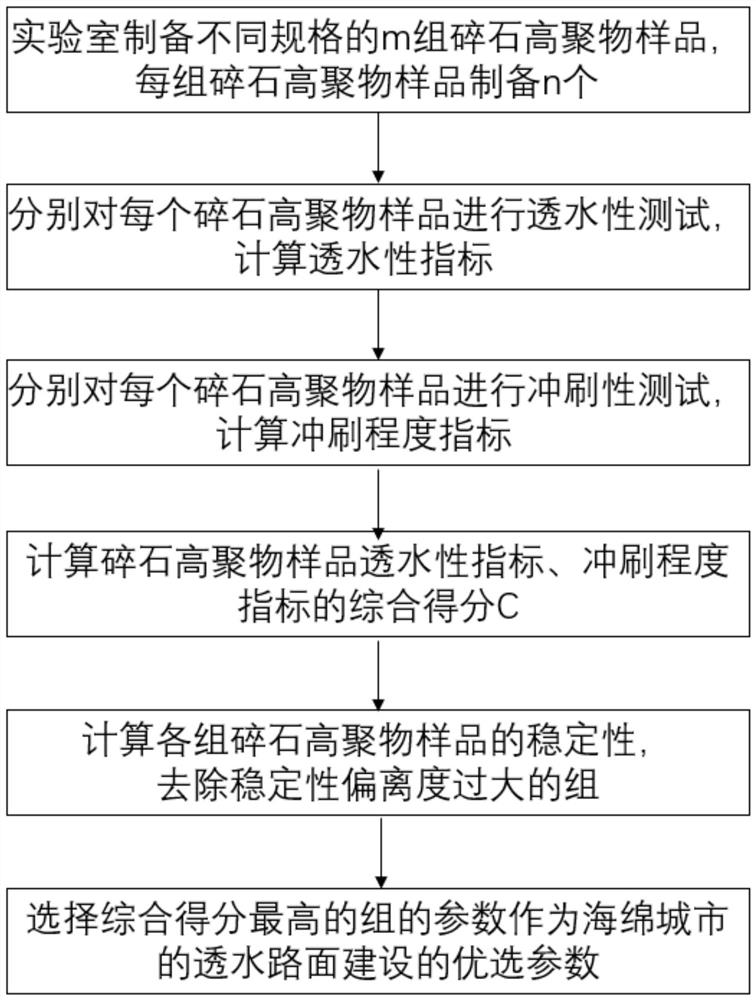

[0057] Such as figure 1 Shown, a kind of gravel polymer porous material is applied to the indoor performance test method of sponge city, comprises the following steps:

[0058] Step 1: The laboratory prepares m groups of gravel polymer samples of different specifications, and each group prepares n gravel polymer samples. The parameters of gravel polymer samples in different groups are different, and the parameters of gravel polymer samples in the same group are completely consistent;

[0059] Step 2: Carry out a water permeability test on each gravel polymer sample, and calculate the water permeability index;

[0060] Step 3: Carry out the scouring test on each gravel polymer sample separately, and calculate the scouring degree index;

[0061] Step 4: Based on the comprehensive score C of the water permeability index and scour degree index of each group of gravel polymer samples, and the stability S of each group, the parameters of the best gravel polymer sample group are se...

Embodiment 2

[0093] The difference between embodiment 2 and embodiment 1 is only: after pouring into the trial mold, the step of inserting and tamping in layers is added.

[0094] Specifically, after step 1.3 is poured into the test mold, layered inserting and pounding can make the mixture denser and the internal pores uniform. Because, during the mixing process of the crushed stone polymer porous material, due to the strong viscosity of the adhesive, when the polymer is wrapped on the surface of the crushed stone particles, there is also a certain degree of stickiness between the particles when they are embedded in each other. Therefore, the mixed After the material is poured into the test mold, it cannot be compacted by its own weight alone; if no measures are taken to deal with it, there will be a large number of holes in the formed test piece, resulting in relatively large defects in the composite material itself.

Embodiment 3

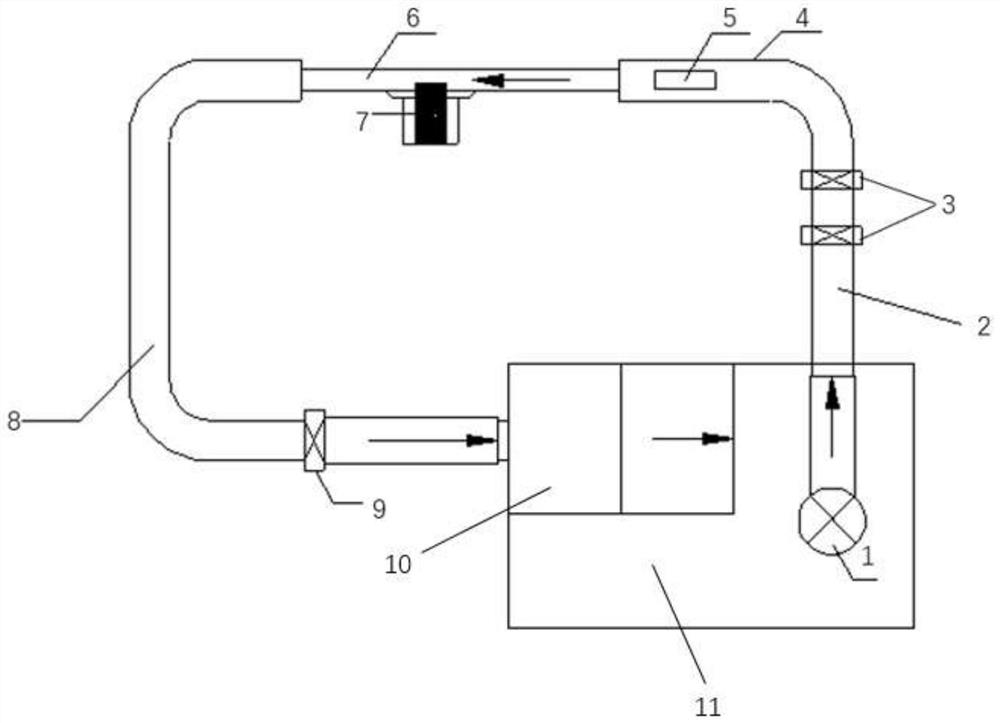

[0096] The difference between embodiment 3 and embodiment 1 is that an experimental equipment for scour test is provided.

[0097] Specifically, such as image 3 As shown, the experimental equipment for the scouring test includes: a water pump 1, the water pump 1 is connected to the water inlet pipe 2, and the other end of the water inlet pipe 2 is connected to the scouring pipe 6, and the bottom of the scouring pipe 6 is provided with a water supply for high accumulation of gravel. The hole where the object sample extends into, the hole is provided with a connection part that is threadedly connected with the sample placement pipe 7, the height of the gravel polymer sample is less than the sum of the heights of the sample placement pipe 7 and the flushing pipe 6, the The water inlet pipe 2 is provided with a flow valve 3 and an ultrasonic flowmeter 5, and the other end of the flushing pipe 6 is connected with the outlet pipe 8, and the outlet pipe 8 is provided with a pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com