Prefabricated concrete beam column connecting joint and connecting method

A prefabricated concrete, beam-column connection technology, applied in the direction of building components, earthquake resistance, building types, etc., can solve problems such as crowded steel bars, inconvenient construction, complex construction technology, etc., to improve ductility and energy consumption capacity, convenient quality inspection, and solve The effect of rebar crowding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

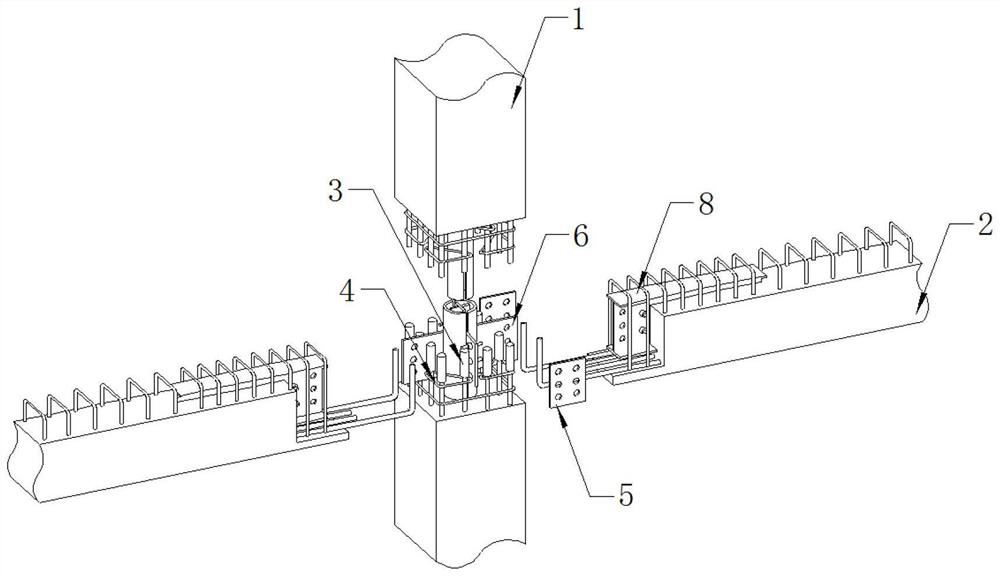

[0036] refer to Figure 1-5 As shown, a precast concrete beam-column connection node includes two precast concrete columns 1, two precast concrete beams 2, several steel bar extrusion sleeves 3, a central fixture and two auxiliary fixtures;

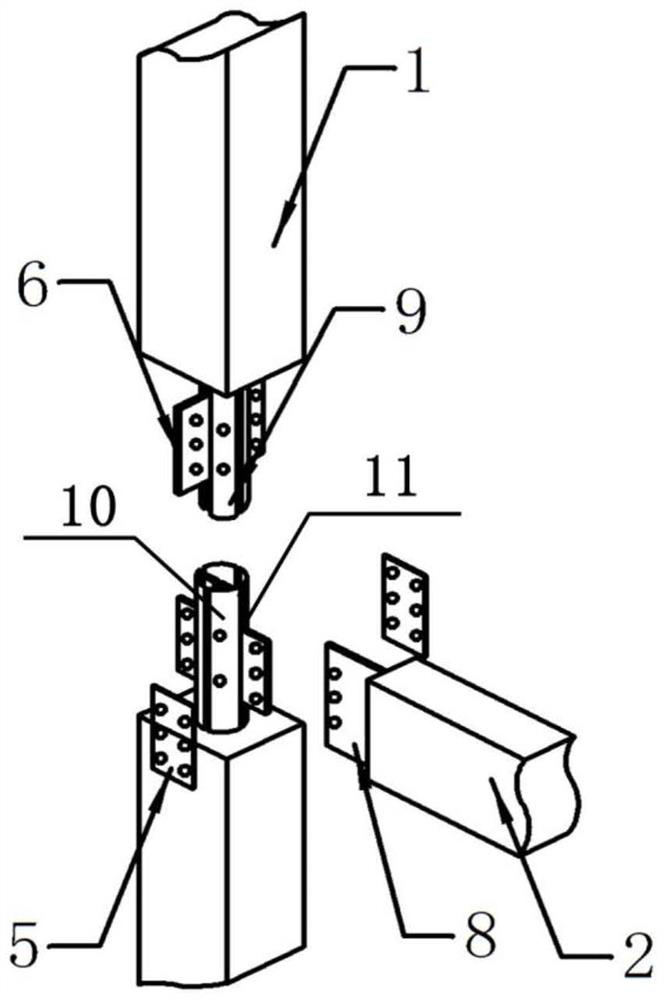

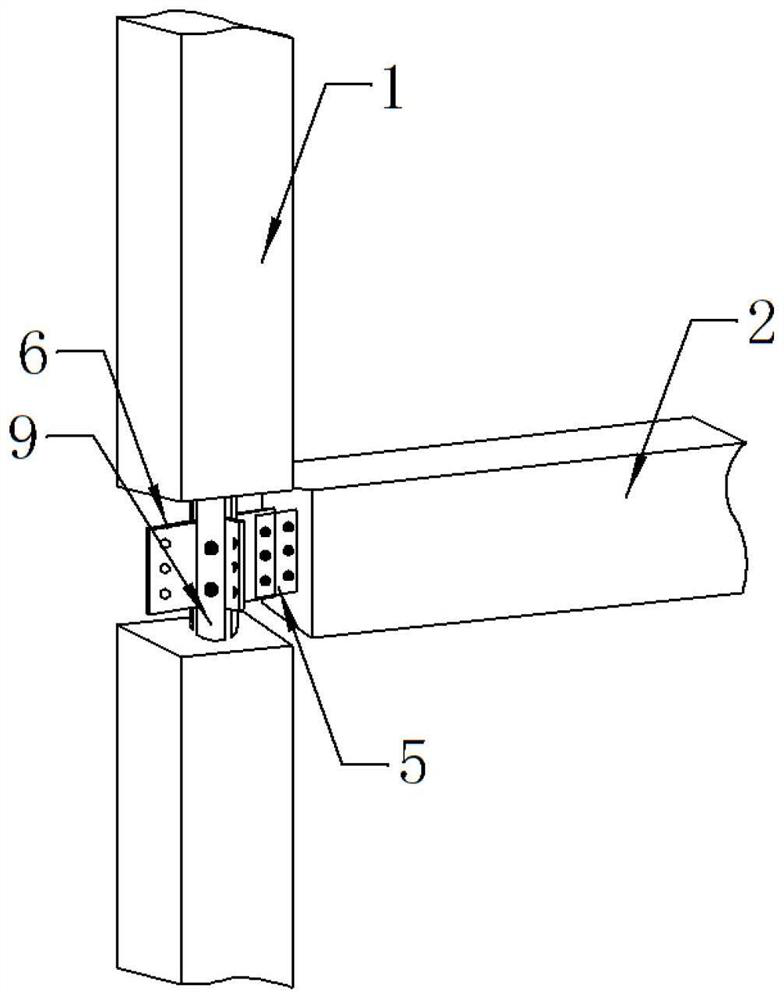

[0037] The central fixture includes a cross tube and a cross plate; both ends of the cross tube are fixedly connected to one end of two prefabricated concrete columns 1 respectively; the cross plate is inserted in the cross tube;

[0038] Auxiliary fixtures include I-beam 8 and two connecting cover plates 5; the sides of I-beam 8 are fixed with reinforcement frames, which are integrally formed with precast concrete beam 2, and the two ends of I-beam 8 protrude from precast concrete beam 2 respectively. Both ends form a fixed end; one end of the I-beam 8 is fixedly connected to the cross plate through two connecting cover plates 5 with screws;

[0039] Further, the steel bar frame is a cage-shaped structural member fixedly connected by a ...

Embodiment 2

[0059] Such as Figure 8-9 As shown, the difference between the fixed piece 10 and the cross plate of this embodiment and the first embodiment is that not only the two fixed pieces 10 that fit together are screwed together, but also the four fixed pieces fixed at intervals on the steel pipe 9 The sheets 10 are fastened together by a long bolt 19 . The long bolts 19 pass through the two gusset plates 6 and are fixedly connected with the two gusset plates 6 , preferably by welding, which can improve the overall strength.

[0060] The two gusset plates 6 are inserted into each other through the slots 13. After being plugged in place, the two gusset plates 6 are also welded along the slots 13, so that the two gusset plates 6 become a whole, and the resistance of the two gusset plates 6 is improved. tensile strength.

Embodiment 3

[0062] A connection method of a prefabricated concrete beam-column connection node in this embodiment also includes the following steps:

[0063] Grouting: After all the structures in Embodiment 1 are connected, concrete is poured on the part between the opposite sides of the two prefabricated concrete columns 1, the cross cylinder and the cross plate, and at the same time the two gusset plates 6 and the I-beam 8 The fixed ends protrude from the cast concrete block. By casting concrete, the two prefabricated concrete columns 1, the cross tube and the cross plate are connected into a whole, and the cross tube and the cross plate are used as the skeleton, and the concrete is used as the frame. Filling improves the connection strength and tensile strength of the connection points of concrete beams and columns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com