GCP assistant injection molding machine capable of improving surface quality of plastic product

A surface quality and injection molding machine technology, applied in the field of GCP auxiliary injection molding machines, can solve problems such as clogging and uneven air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

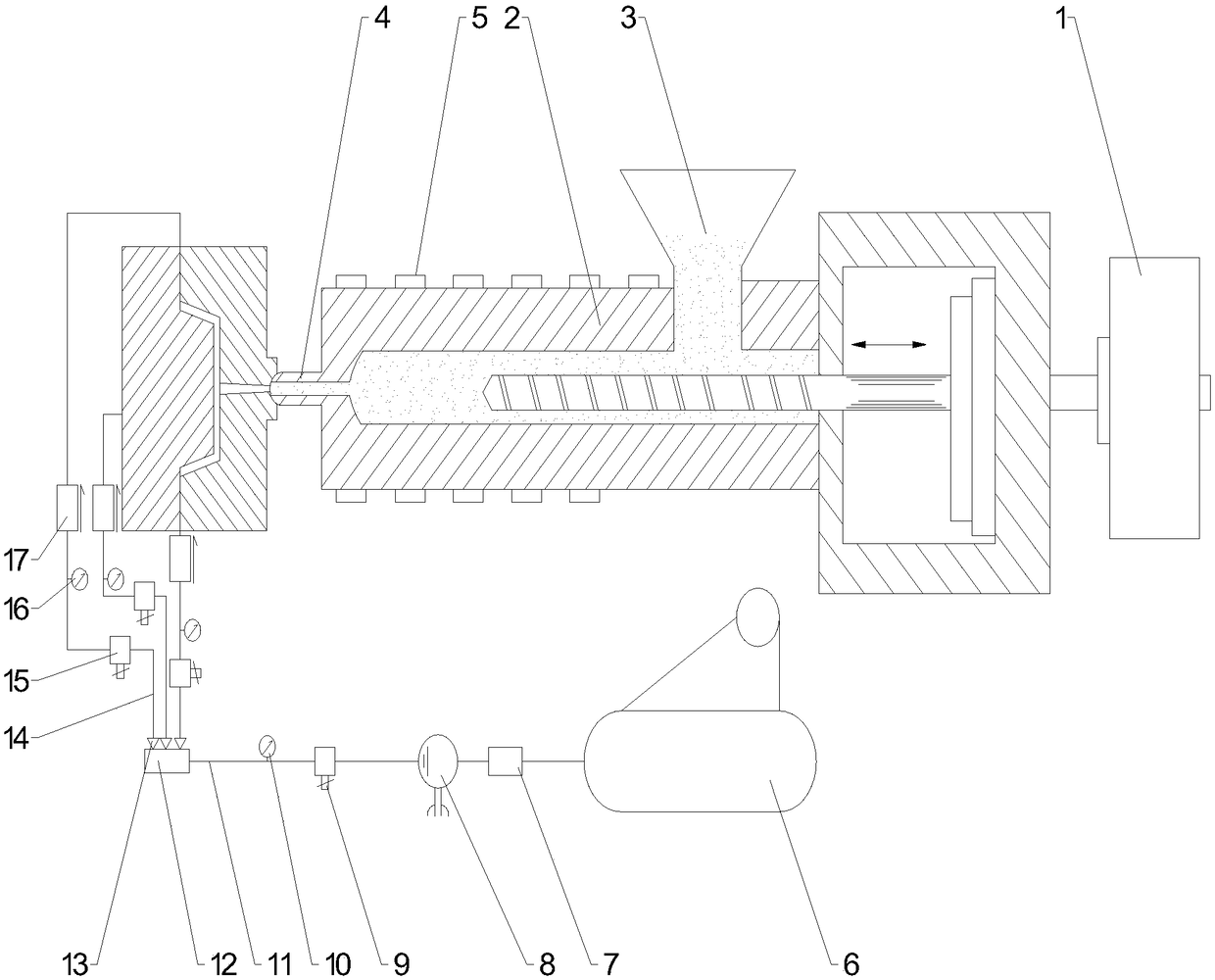

[0017] The concept, specific structure and specific effects of the present invention will be clearly and completely described below in conjunction with the embodiments and drawings, so as to fully understand the purpose, features and effects of the present invention. The various technical features created by the present invention can be combined interactively on the premise of not conflicting with each other.

[0018] see figure 1 , a GCP auxiliary injection molding machine capable of improving the surface quality of plastic parts, is characterized in that it includes an injection molding structure and a gas back pressure device, and the injection molding structure includes a driving device 1, an injection cavity 2, a feed hopper 3, a nozzle 4 and a heating device 5, the injection chamber 2 is cylindrical, the driving device 1 is arranged at the rear of the injection chamber 2, the nozzle 4 is arranged at the front of the injection chamber 2, and the feeding hopper 3 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com