High-stability ink and preparation method thereof

A high-stability, ink technology, used in inks, household appliances, applications, etc., can solve the problems of slow drying speed, difficult to overcome the dryness of ink printing, reverse printing of printed materials, etc., to reduce the emission of VOCs and promote the effect of penetration and drying. , Improve the effect of printing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

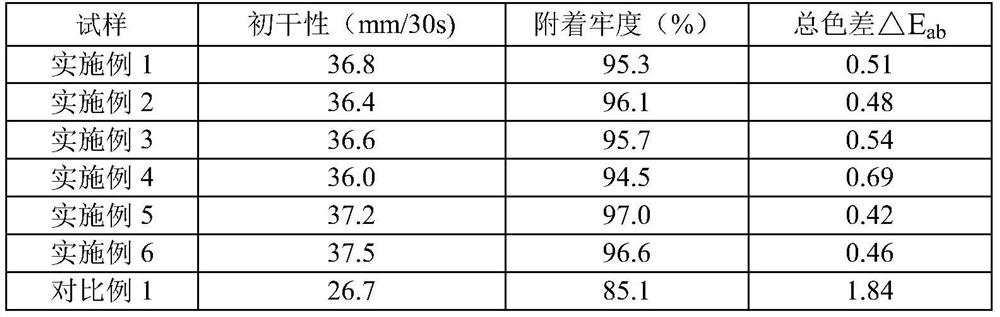

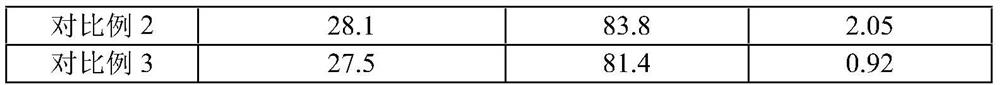

Examples

preparation example 1

[0035] A kind of vegetable oil for high stability printing ink, its preparation method is as follows:

[0036] Take 20kg of castor oil into the reactor, heat up to 55±2°C, add 6kg of maleic anhydride, stir at 60r / min for 5min, then add 0.5kg of CaO-ZrO 2 The catalyst was reacted for 2 hours, and the filtrate was filtered to obtain esterified modified castor oil. Weigh 9kg of esterified modified castor oil, 3kg of linseed oil and 3kg of palm oil into a stirring tank, stir and disperse evenly to obtain final product.

preparation example 2

[0038] A kind of vegetable oil for high stability printing ink, its preparation method is as follows:

[0039] Take 20kg of castor oil into the reactor, heat up to 55±2°C, add 6kg of maleic anhydride, stir at 60r / min for 5min, then add 0.5kg of CaO-ZrO 2 The catalyst was reacted for 2 hours, and the filtrate was filtered to obtain esterified modified castor oil. Weigh 6kg of esterified modified castor oil, 2kg of linseed oil and 2kg of palm oil into a stirring tank, stir and disperse evenly to obtain final product.

preparation example 3

[0041] A kind of vegetable oil for high stability printing ink, its preparation method is as follows:

[0042] Take 20kg of castor oil into the reactor, heat up to 55±2°C, add 4kg of maleic anhydride, stir at 60r / min for 5min, then add 0.5kg of CaO-ZrO 2 The catalyst was reacted for 3 hours, and the filtrate was filtered to obtain esterified modified castor oil. Weigh 7kg of esterified modified castor oil, 2.5kg of linseed oil and 2.5kg of palm oil into a stirring tank, stir and disperse evenly to obtain final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com