Aminated modified lignin-based polyurethane foam, and preparation method and application thereof

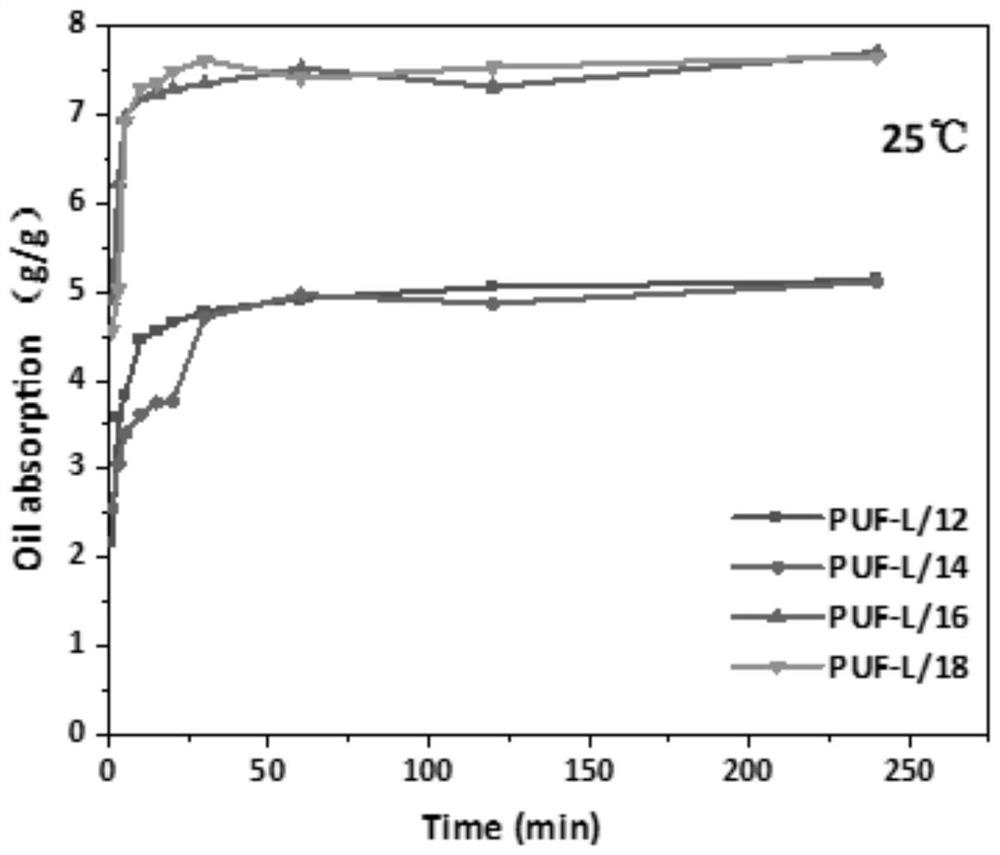

A technology of polyurethane foam and aminated lignin, which is applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of poor lipophilicity and hydrophobicity, poor adsorption effect of oil substances, etc., achieve high adsorption and improve hydrophobicity lipophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

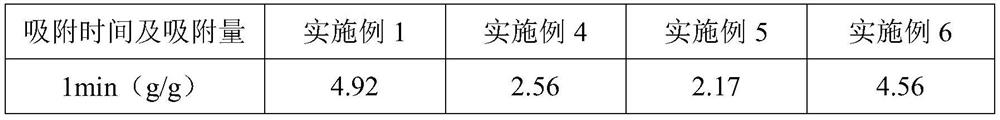

Examples

Embodiment 1

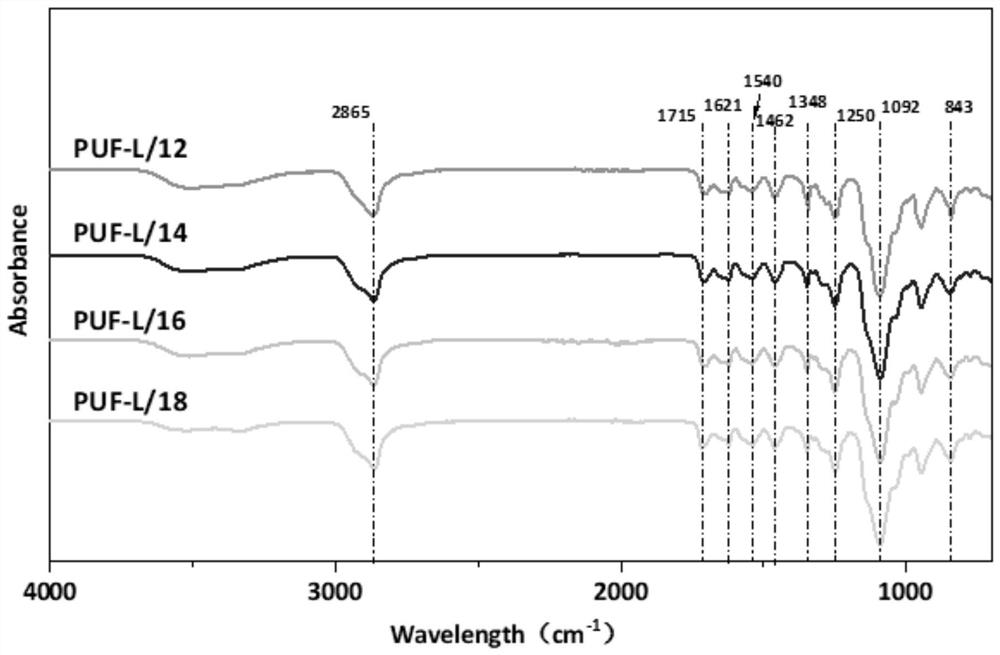

[0032] A preparation method of aminated modified lignin-based polyurethane foam, comprising the following steps:

[0033] S1. Weigh 10g of lignin into a 250mL beaker, add 200mL of ultrapure water, adjust the pH of the lignin solution to 8 with sodium hydroxide, add the lignin solution into a 250mL three-necked flask, and stir at 50°C for 30min to make the lignin solution The element is fully dissolved, and then the temperature is raised to 90 ° C, and 2 g of formaldehyde solution is added dropwise. After 10 minutes of reaction, 2 g (20%) of hexadecylamine is added and kept for 4 hours. After the reaction is completed, the reaction solution is added to 1000 mL of 90 ℃ hot water, adjust pH = 2, stand overnight and then filter with suction, and continuously add water to wash until the filtrate is neutral, place the solid at 40 ℃ and vacuum dry to constant weight to obtain aminated modified wood white;

[0034] S2. Weigh 20g of PEG400, 0.1g of dibutyltin dilaurate, 0.1g of A33 (t...

Embodiment 2

[0036] The amount of cetylamine added in step S1 of Example 2 is 15% (1.5 g) of the lignin mass, and the others are the same as in Example 1.

Embodiment 3

[0037] The amount of cetylamine added in step S1 of Example 3 is 25% (2.5 g) of the lignin mass, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com