Side edge rubber buckling chain belt

A tape and plastic chain technology, applied in the field of machinery, can solve the problems of easy falling off of leak-proof strips, tape deviation and tearing, complex casting cost, etc., to increase power consumption and layout space, improve tear resistance and tensile strength, The effect of saving facility investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

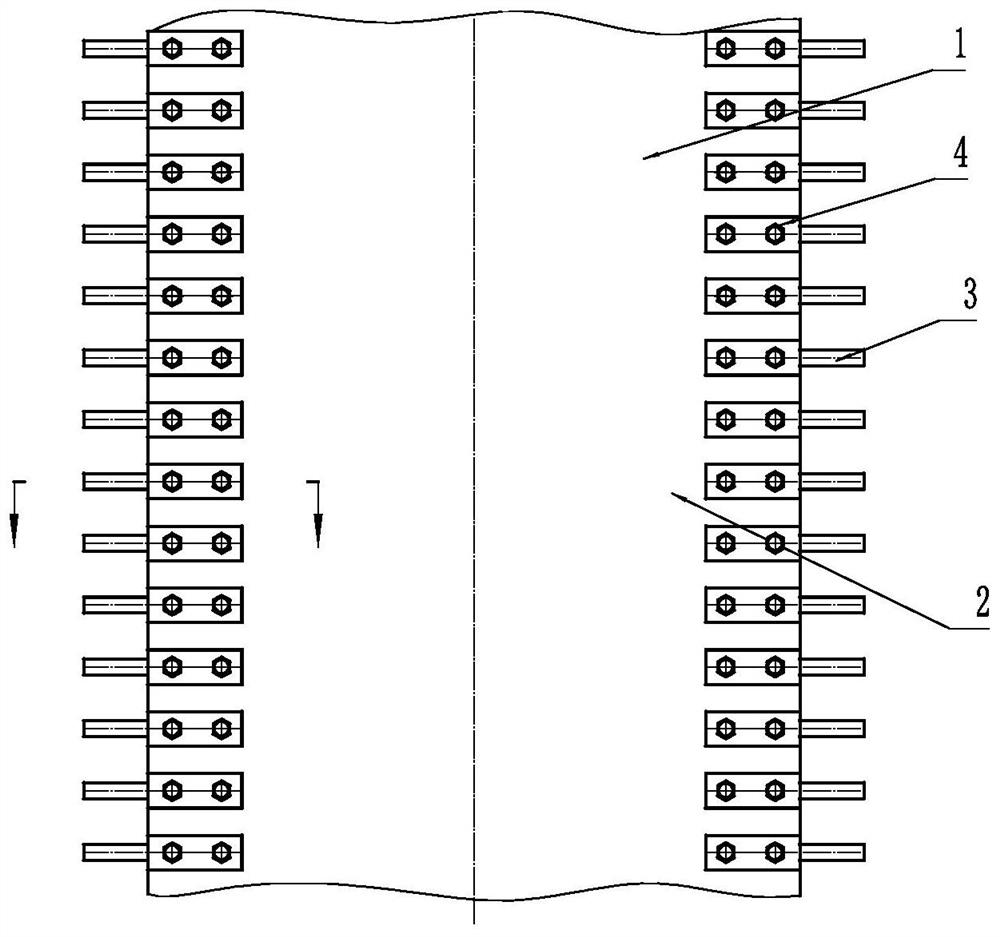

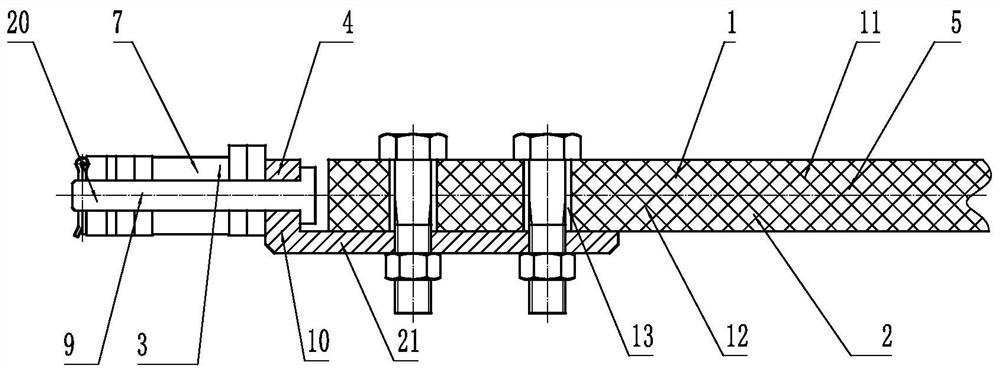

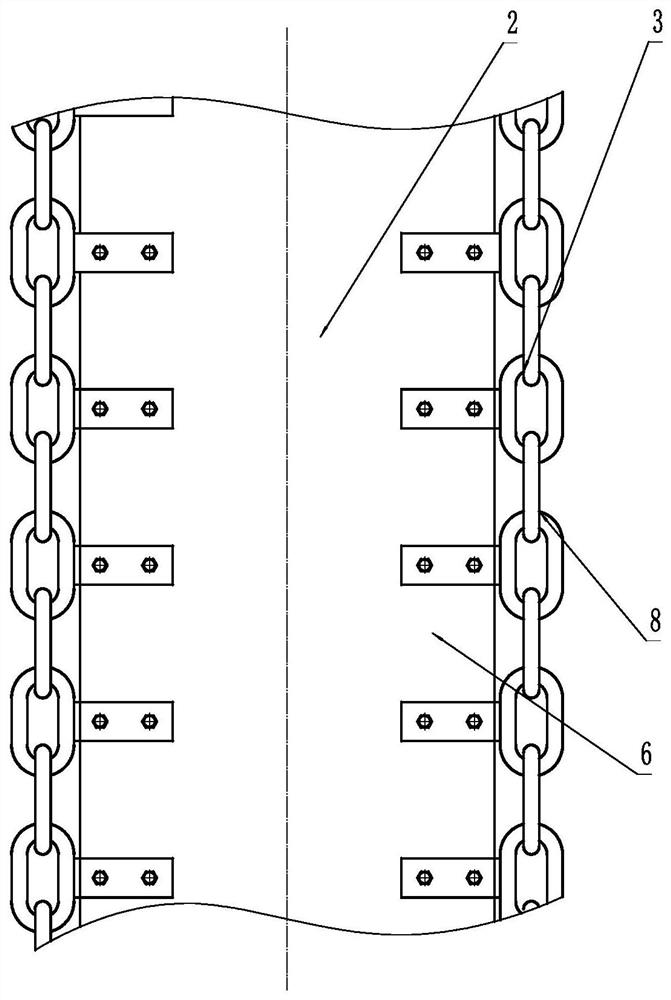

[0216]1-buckle side rubber chain belt, 2-conveyor belt, 3-drive chain, 4-chain connecting conveyor belt parts, 5-fixed link shaft tape, 6-fixed ring chain tape, 7-roller chain, 8- Ring chain, 9-buckle sprocket shaft, 10-fixed buckle sprocket shaft, 11-ring chain, 12-side shaft rubber chain belt, 13-fixed chain link shaft through hole, 14-fixed chain link shaft blind hole, 15-Fixed chain link shaft seam edge, 16-Fixed chain link shaft buckle edge, 17-Fixed chain link shaft bonding edge, 18-Fixed chain link shaft nut, 19-Fixed chain link shaft warp and weft cloth, 20-Fixed chain Knuckle shaft side overlapping belt, 21-steep turn guide wheel, 22-ring chain buckle, 23-buckle connection ring chain structure, 24 side ring chain tape, 25-side buckle belt, 26-fixed chain link Shaft and screw parts, 27 connecting ring chain through hole, 28-nut, 29-screw rod, 30-screw, 31-folding belt, 32-bucket plate, 33-square buckle plate, 34-circular buckle plate, 35 -Chain piece, 36-Double hole c...

specific Embodiment approach

[0217] Example 1

[0218] like Figure 1 to Figure 2 As shown, the buckle side rubber chain belt 1 includes a conveyor belt 2, a drive chain 3 and a chain connecting conveyor belt piece 4, the conveyor belt 2 includes a fixed link shaft tape 5, and the drive chain 3 includes a roller chain 7, and the roller chain 7 Including buckle sprocket shaft 9, chain connection conveyor belt part 4 includes fixed buckle sprocket shaft part 10, fixed buckle sprocket shaft part 10 connects buckle sprocket shaft 9 and fixed chain link shaft tape 5 to form side shaft rubber chain belt 12, fixed buckle The sprocket shaft part 10 and the buckle sprocket shaft 9 are integrated, and the side of the fixed chain link shaft tape 5 is provided with a fixed chain link shaft through hole 13. When using the fixed chain link shaft through hole 13, the fixed buckle sprocket shaft part 10 will buckle The sprocket shaft 9 is fixed on both sides of the fixed chain link shaft adhesive tape 5, and the fixed c...

Embodiment 2

[0224] like Figure 12 As shown, when the fixed chain link shaft nut 18 is used, the fixed chain link shaft nut 18 is arranged on the side of the fixed chain link shaft tape 5, and the fixed chain link shaft screw member 26 is set on the drive chain 3, so that the fixed chain link shaft screw Part 26 fixes the sprocket shaft 9 on both sides of the fixed chain link shaft adhesive tape 5, and the fixed chain link shaft screw part 26 is connected with the chain sprocket shaft 9 splits.

[0225] It is also possible to fix the sprocket shaft 9 on one side of the fixed chain link shaft tape 5 by the fixed chain link shaft screw member 26 .

[0226] can also be as Figure 13 As shown, the fixed chain link shaft screw member 26 is integrated with the chain wheel shaft 9 .

[0227] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com