Aluminum material machining and producing cutting equipment

A technology for cutting equipment and aluminum materials, applied in the direction of metal processing equipment, metal processing, metal processing machinery parts, etc., can solve problems such as troubles, melting of aluminum scraps, sticking to cutting pieces, etc., to prevent rolling, increase production quality, prevent The effect of excessive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

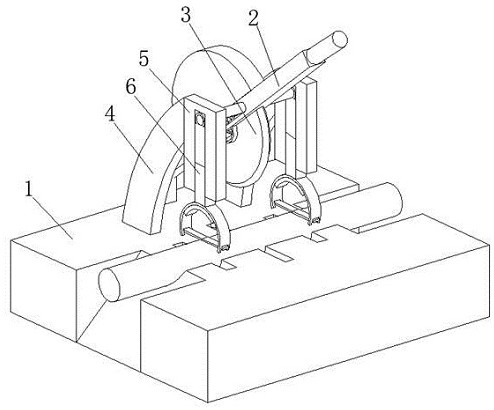

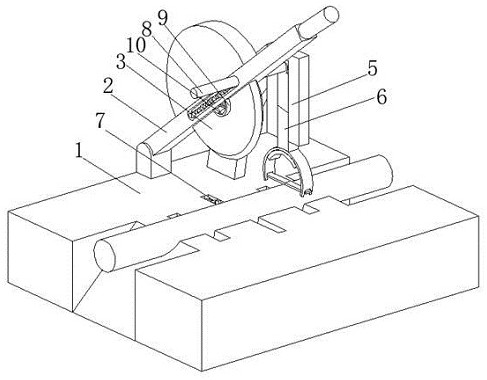

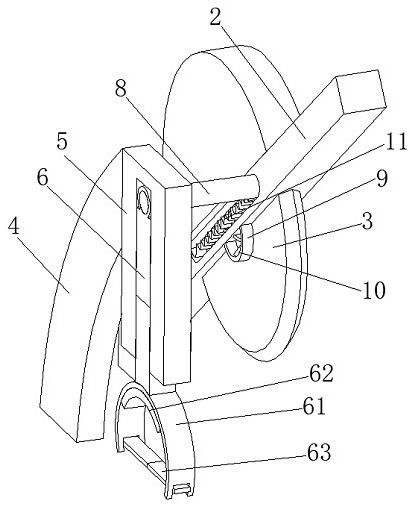

[0025] A kind of aluminum processing and production cutting equipment, such as Figure 1-Figure 6 As shown, it includes a workbench 1, the top of the workbench 1 is connected with a pressure bar 2 through a torsion spring, the surface of the pressure bar 2 is provided with a cutting machine 3, the top of the workbench 1 is fixedly connected with a support plate 4, and the support plate 4 The front part is fixedly connected with the limiting plate 5, and the inner wall of the limiting plate 5 is slidably connected with the telescopic rod 6, and the bottom of the telescopic rod 6 is fixedly connected with the arc plate 61, and the lower surface of the arc plate 61 is fixedly connected with the rubber block 62. The inner wall of the shaped plate 61 is rotatably connected with a rotating plate 63 through a torsion spring, the inner wall of the telescopic rod 6 is rotatably connected with a transmission rod 8, and the surface of the transmission rod 8 is fixedly connected with a shr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com