Method and system for correcting water flow inertia time constant in water turbine and diversion system model

A water diversion system and water flow inertia technology, applied in data processing applications, special data processing applications, instruments, etc., can solve problems such as the deviation between the actual value of the water flow inertia time constant and the design value, and achieve simple test methods, accurate test values, and improved The effect of efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

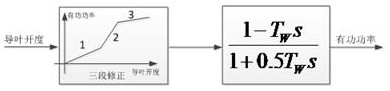

Method used

Image

Examples

example

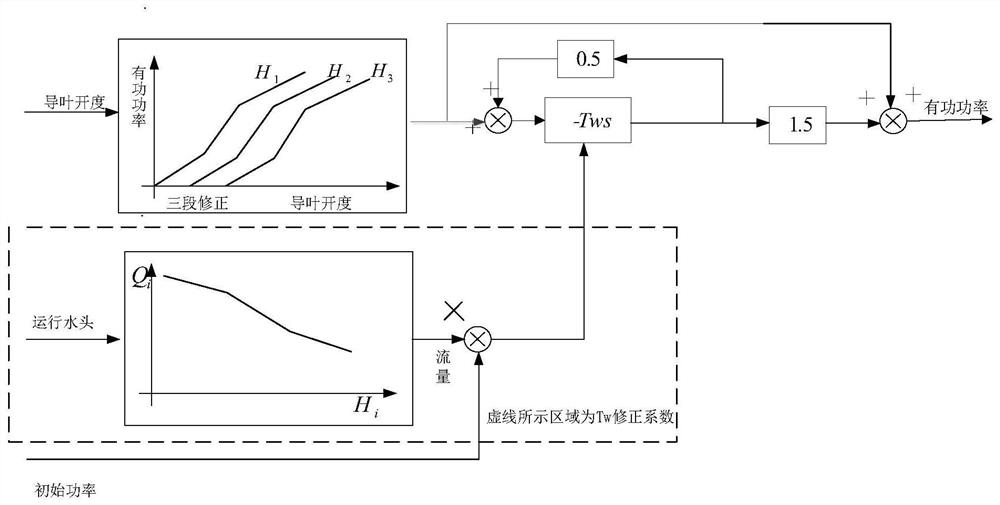

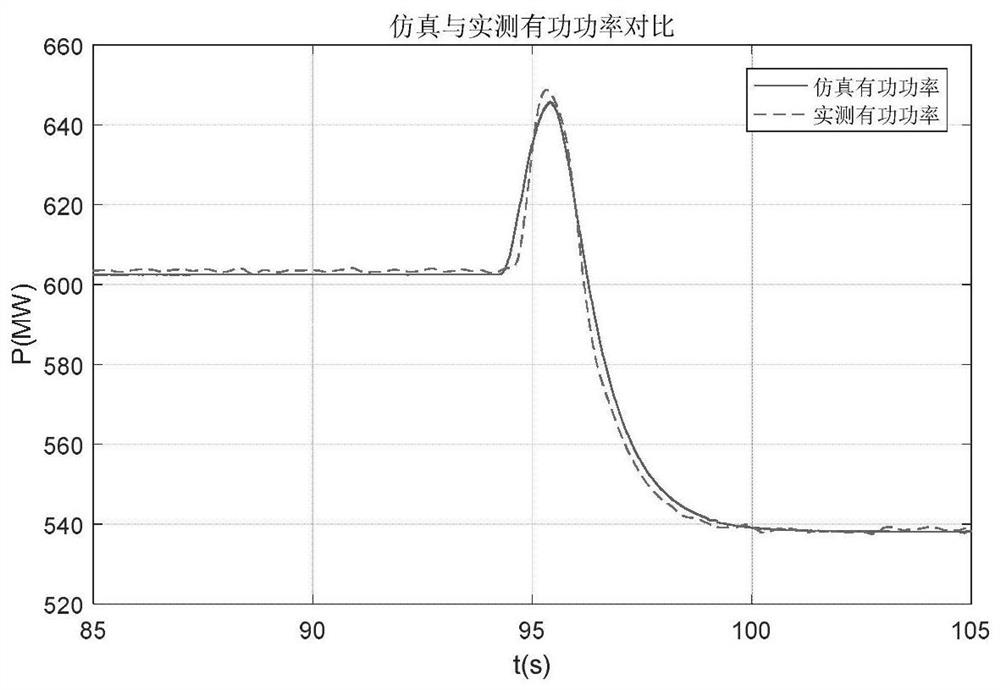

[0082] A giant hydropower station, the hydraulic turbine type is vertical shaft mixed flow, the water diversion system adopts single-pipe stand-alone mode, rated power is 600MW, rated water head is 111m, and rated flow rate is 597.95m 3 / s, the design value of water flow inertia time constant is 2s.

[0083] Under three operating water heads of 108m, 113.8m, and 117m respectively, the unit has active power of 240MW, 480MW, and 600MW, and a given step of the guide vane is applied to the governor, and the actual active power reverse curve is measured; the statistics of the unit under the three water heads When the rated load is 600MW, the flow rate is 601.32m 3 / s, 561.72m 3 / s, 548.49m 3 / s, substitute the head and flow data into figure 2 The model shown (f(H i )=Q i (i=1, 2, 3...)), then the three-stage correction model of the water flow inertial time constant coefficient can be obtained.

[0084] The water flow inertia time constant correction coefficient is:

[0085]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com